Rotary type hanging tool

A rotary and hanger technology, applied in tools, manufacturing tools, casting and molding equipment, etc., can solve problems such as the inability to meet the needs of rapid and efficient drying in mass production, uneven drying degree of mold shells, and different drying degrees. Easy to manufacture, simple rotating structure, and the effect of improving drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

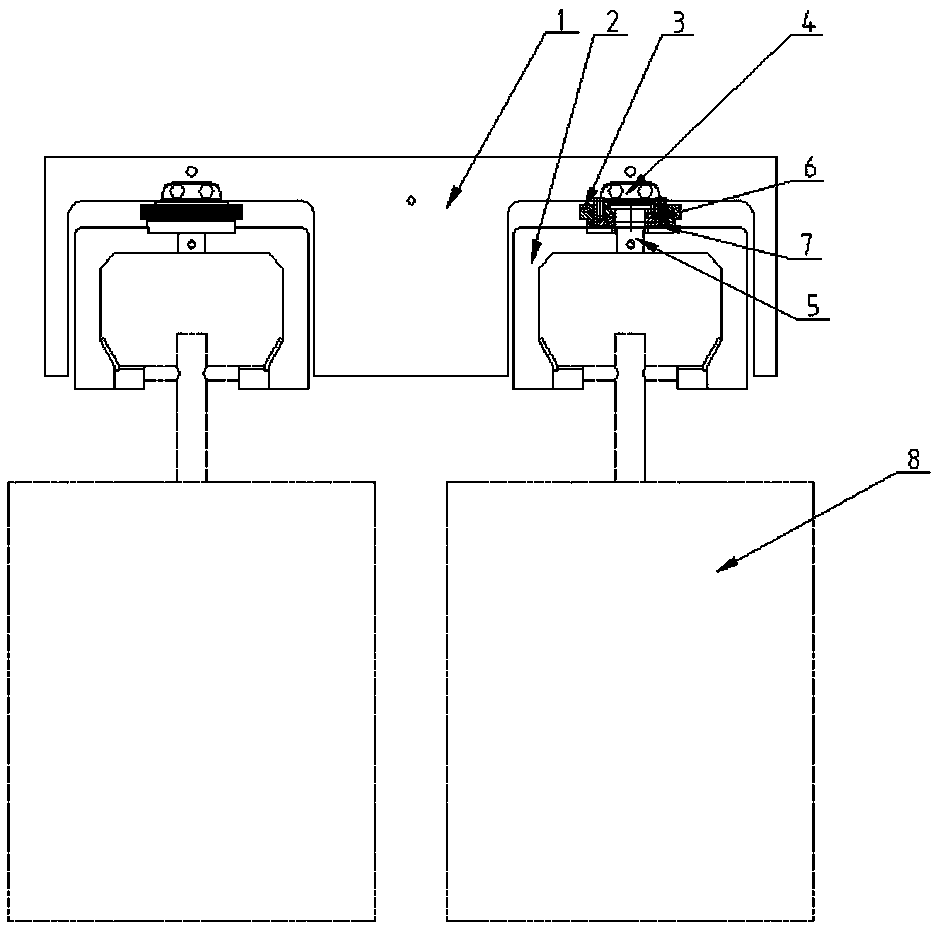

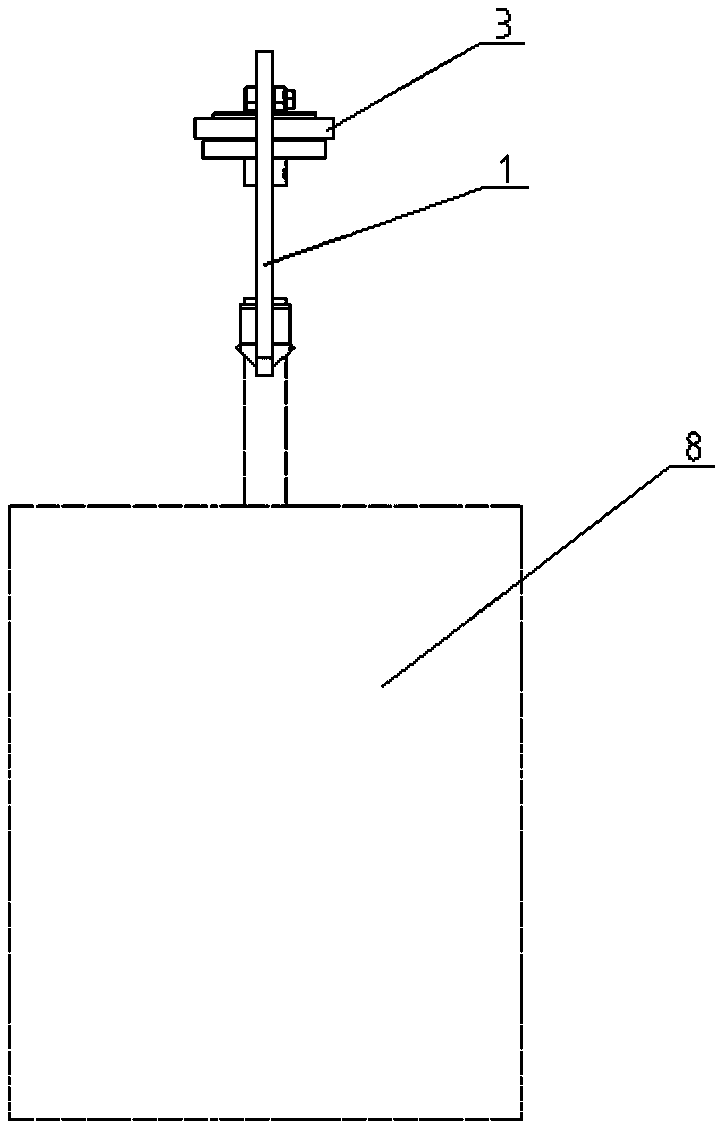

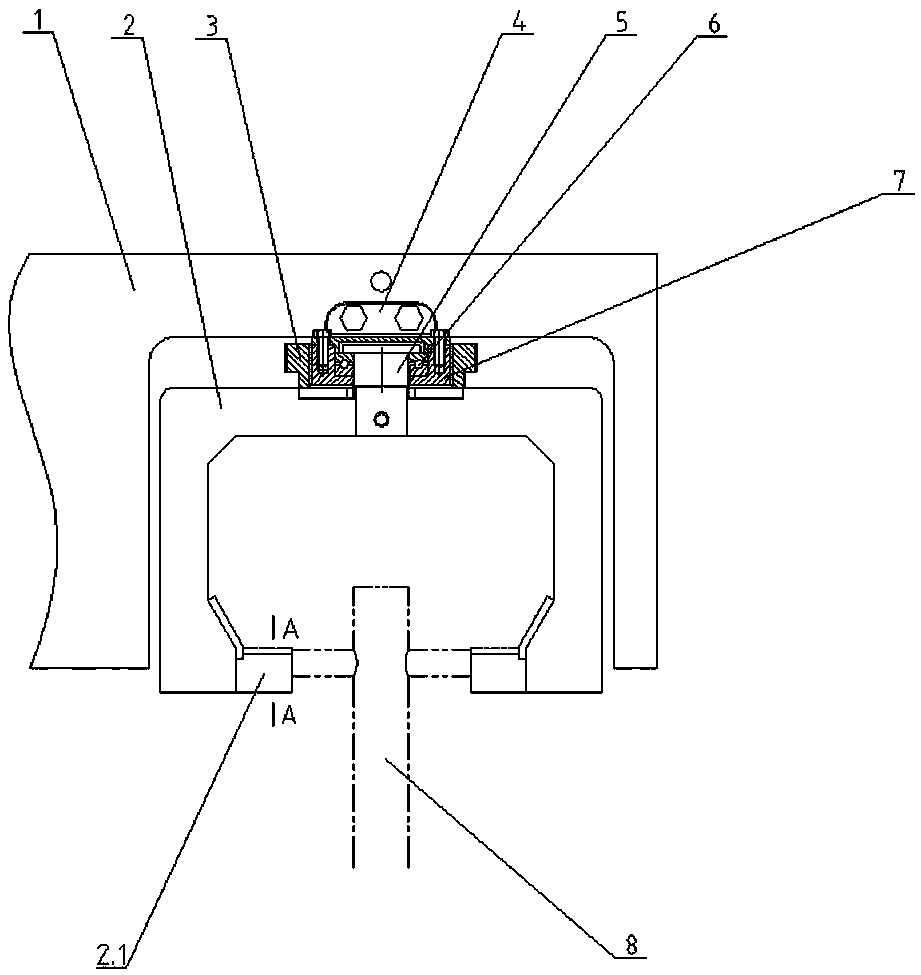

[0017] The rotary hanger shown in the accompanying drawing is a hanger for precision casting to hang the workpiece formwork, and it includes a base 1, a hook 2, a friction wheel 3, an upper cover 4, a mandrel 5, a bearing 6 and a bearing 7. The base 1 is a carrier component of the hanger, which is a horizontally vertical rectangular plate, and the bases 1 arranged in sequence in the formwork drying production line are connected by a chain. Each base 1 is used as a transmission unit. In the present embodiment, two rectangular grooves with symmetrical positions and opening downwards are provided on the bottom side of the base 1 , and the grooves are used for placing the hook 2 . Described hook 2 shapes C-shaped plate frame, and the two sides of the gap reserved in the middle of the bottom form a pair of equal-length inner hooks 2.1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com