Rotary evaporator capable of automatically controlling continuous feeding and discharging

A rotary evaporator, feeding and discharging technology, applied in the field of rotary evaporators, can solve the problems of low degree of automation, inseparable from experimenters, and inability to continuously feed and discharge materials, so as to reduce workload, avoid manual operations, and ensure continuous and efficient work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

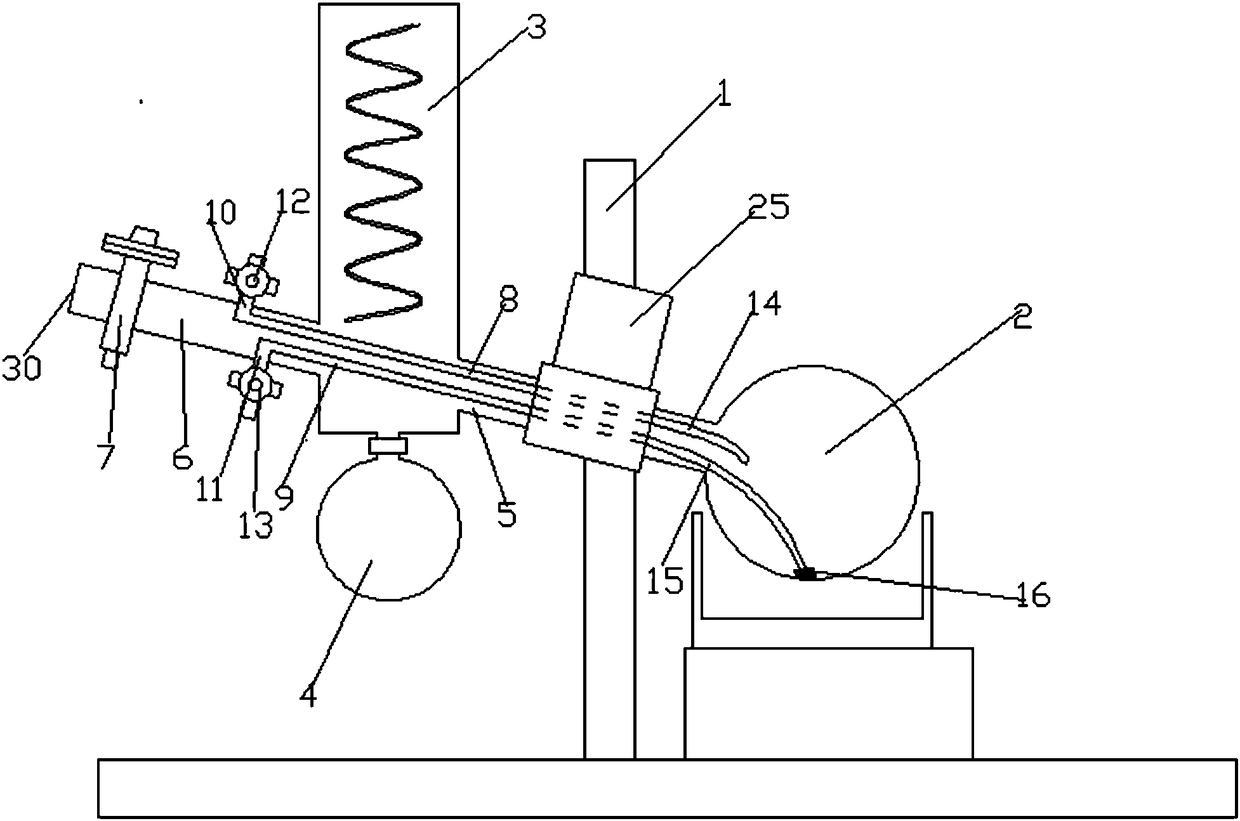

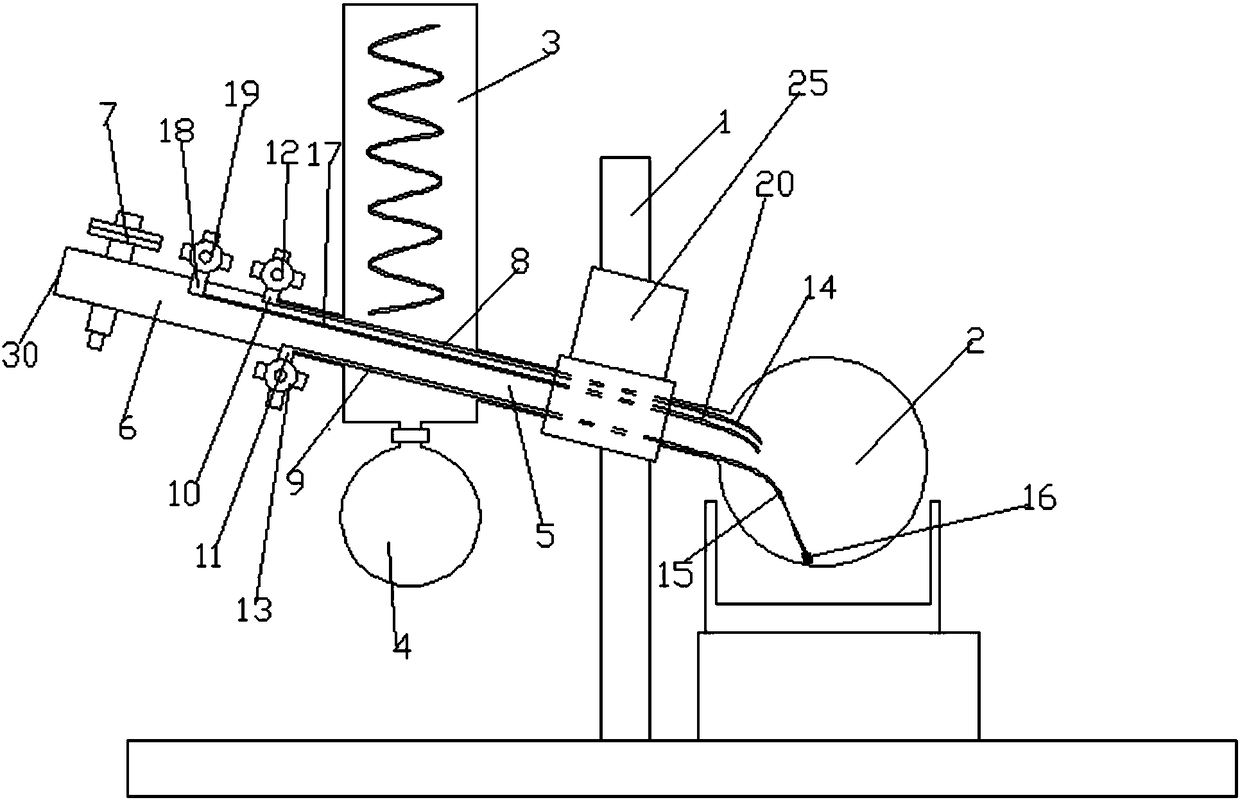

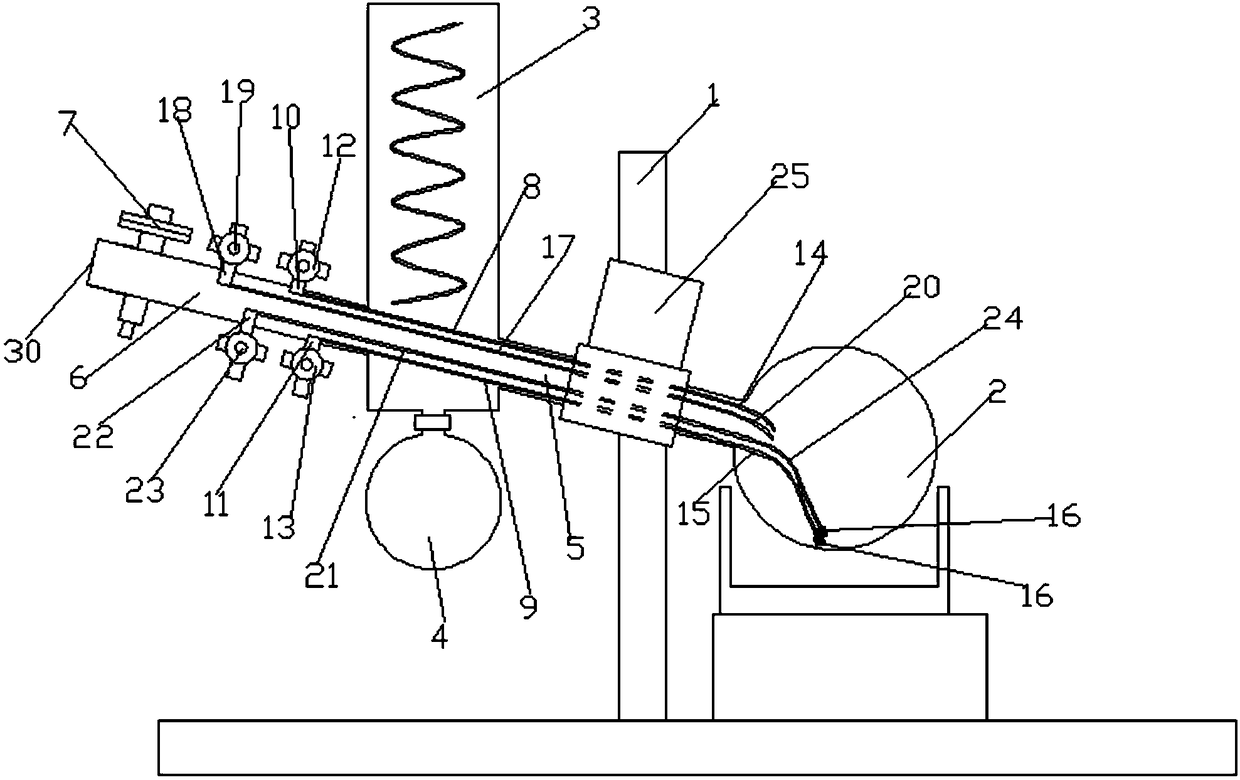

[0033] Such as figure 1 As shown in the structure, the rotary evaporator of the present invention includes a support 1, and a rotary motor 25 for controlling the rotation of the rotary evaporator (the rotary evaporator of the present invention can also be provided with a control for controlling the parameter speed of the rotary evaporator. panel, not shown). A detachable distillation bottle 2 and a condenser 3 are fixed on the support 1, the distillation bottle 2 and the condenser 3 are connected to realize liquid distillation, and the bottom of the condenser is connected with a receiving bottle 4 for receiving evaporation solvent. The bottom of the receiving bottle 4 may be provided with a channel for discharging fractions and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com