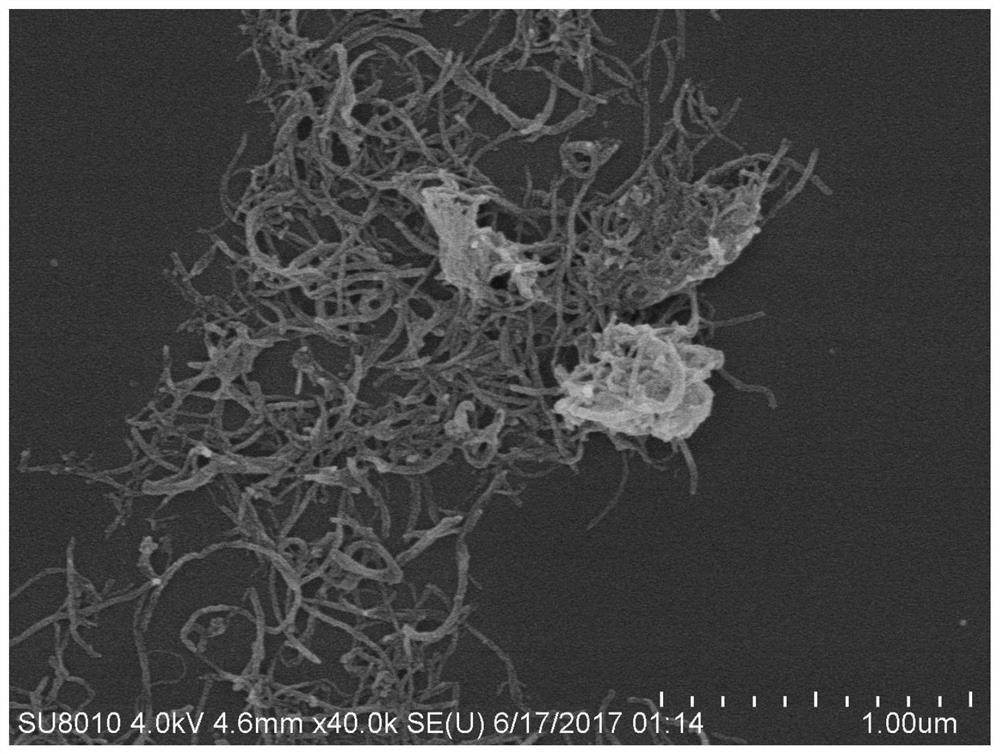

Preparation method of trimanganese tetraoxide/nitrogen-doped carbon nanotube composite material

A technology of trimanganese tetraoxide and nitrogen-doped carbon, which is applied to structural parts, electrical components, battery electrodes, etc., can solve the problems of poor conductivity, poor stability, and low catalytic performance, and achieve superior performance and good ORR performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention proposes a preparation method of trimanganese tetraoxide / nitrogen-doped carbon nanotube composite material, which specifically includes the following steps:

[0051] S1: Preparation of oxidized exfoliated carbon nanotubes;

[0052] S2: preparing the exfoliated carbon nanotubes in step S1 into a certain concentration of exfoliated carbon nanotube dispersion, and then adding a certain amount of concentrated ammonia water to make the dispersion solution into an alkaline dispersion solution with alkalinity;

[0053] S3: Make the manganese salt into a certain concentration of manganese salt solution, and add the manganese salt solution and nitrogen source to the alkaline dispersion solution in step S2, after stirring for a certain period of time, put the alkaline dispersion solution into a constant temperature ultrasonic The reactor device reacts for a certain period of time to obtain a dispersed solution;

[0054] S4: The dispersion solution in step S...

Embodiment 1

[0082]将100mL浓硫酸倒入500mL的圆底烧瓶中,然后加入1g多壁碳纳米管,通过磁力搅拌器搅拌得到酸性分散溶液。

[0083] 然后再向烧瓶中加入100mL的浓硫酸并搅拌,向分散液中缓慢地加入3g高锰酸钾,搅拌30min得到紫红色的混合物。

[0084] 将上述紫红色的混合物放置在80℃水浴中加热2h并保持搅拌,而后向混合物中缓慢加入20mL的过氧化氢和体积为300mL的冰块,得到黄色的分散溶液;将上述黄色溶液通过离心、10%的盐酸、二次水洗涤多次再离心,最终冷冻干燥得到剥离碳纳米管。

[0085] 往100mL的玻璃瓶中加入50mL 1mg / mL的剥离碳纳米管水分散液后,加入2mL的浓氨水并充分搅拌,再加入20mL 1mg / mL的高锰酸钾溶液,混合均匀后再滴加1.0mL的联氨,盖上玻璃瓶盖子后将玻璃瓶放置于超声反应器装置的80℃水浴溶液中超声反应10h。

[0086] 最后将反应得到的混合物通过反复抽滤、二次水洗涤多次,最后真空干燥得到氮掺杂剥离的碳纳米管负载四氧化三锰材料。

[0087] 实施例子2

[0088] 将300mL浓硫酸倒入装有2g多壁碳纳米管的500mL的圆底烧瓶中,通过磁力搅拌器搅拌得到分散溶液。

[0089] 向分散液中缓慢加入6g高锰酸钾,搅拌30min得到紫红色的混合物。

[0090] 将上述的紫红色混合物放置在80℃水浴中加热2h并保持搅拌,再向混合物中缓慢加入20mL的过氧化氢和体积为500mL的冰块,得到黄色溶液,将黄色溶液通过离心、10%的盐酸、二次水洗涤多次再离心,最后冷冻干燥得到剥离碳纳米管。

[0091] 往100mL的玻璃瓶中加入50mL 1mg / mL的剥离碳纳米管水分散液,加入2mL的浓氨水并充分搅拌,再加入15mL2mg / mL的高锰酸钠溶液,混合均匀后加入1.0g尿素,盖上玻璃瓶盖子后将玻璃瓶放置于超声反应器装置的85℃的水浴溶液中超声反应12h。

[0092] 最后将反应得到的混合物通过反复抽滤、二次水洗涤多次,最后真空干燥得到氮掺杂剥离的碳纳米管负载四氧化三锰材料。

[0093] 实施例子3

[0094] 将300mL浓硫酸倒入装有2g多壁碳纳米管的500mL的圆底烧瓶中,通过磁力搅拌器搅拌得到分散溶液。

[0095] 向...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com