Maintenance troubleshooting method based on TFM three-dimensional information flow model

A technology of information flow and models, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of poor model versatility, inability to meet the requirements of complex and large-scale system fault diagnosis, and heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The content of the present invention will be described below in conjunction with specific embodiments.

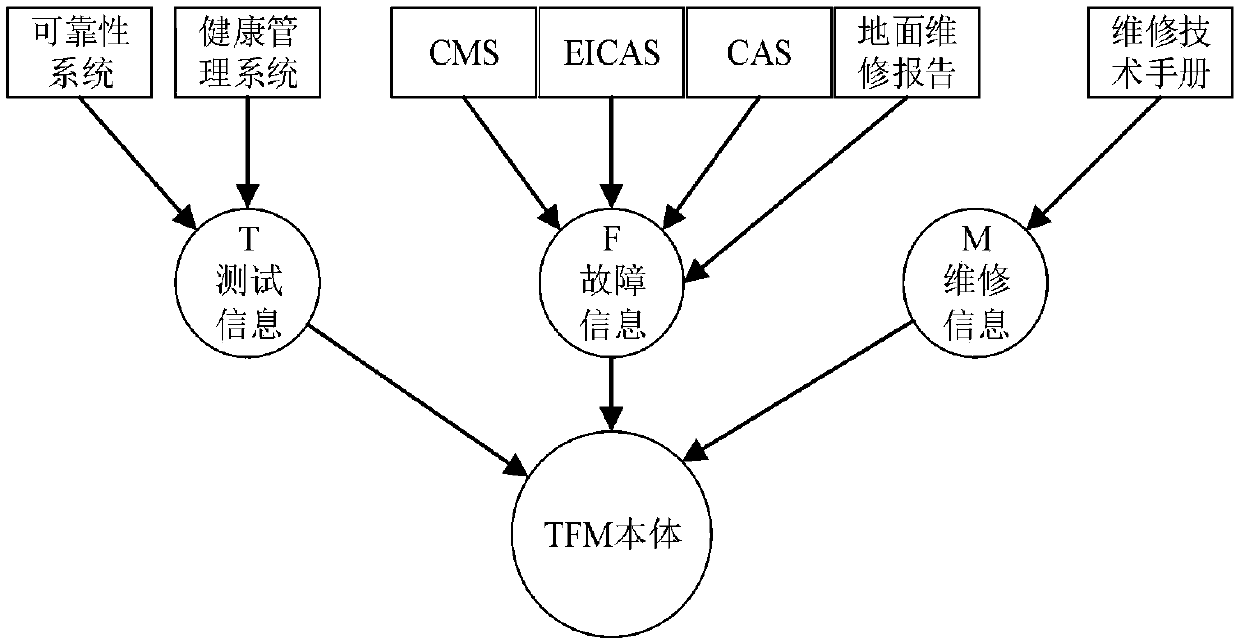

[0065] Such as Figure 1-12 As shown, it is a schematic diagram of the flow and operation steps of the maintenance and troubleshooting method based on the TFM three-dimensional information flow model of the present invention.

[0066] The basic idea of maintenance and troubleshooting based on the TFM three-dimensional information flow model is to aim at the collaborative optimization of fault diagnosis and troubleshooting, based on the comprehensive analysis of aircraft system principles, system reliability design, and maintenance technical manuals, and to "test, fault, "Maintenance" low-dimensional information is integrated and mapped to the "test-fault-maintenance" three-dimensional information model to achieve efficient diagnosis and troubleshooting (as shown in the attached manual figure 1 shown).

[0067] In order to explain the implementation method of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com