Lightweight shield shelter wallboard with infrared stealth function and preparation method thereof

A bulkhead panel and functional technology, applied in chemical instruments and methods, shielding materials, magnetic field/electric field shielding, etc., can solve the problems that are difficult to meet the requirements of high shielding shelters, high structural foam density, and does not involve infrared stealth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a method for preparing a shielded shelter panel with infrared stealth function described in the above technical solution, comprising the following steps:

[0045] The honeycomb core material coated with the temperature control coating, the first panel coated with the temperature control coating and the second panel coated with the temperature control coating are bonded to obtain a shielding party with infrared stealth function. bulkhead plating;

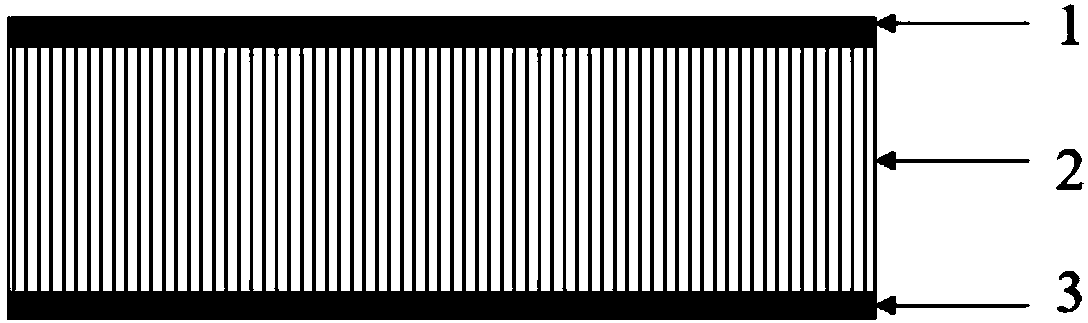

[0046] Both the first panel layer and the second panel layer include multiple layers of surface metallized fiber fabrics.

[0047] In the present invention, the honeycomb core material layer whose surface is coated with a temperature control coating is preferably prepared according to the following method:

[0048] The fiber raw paper coated with the temperature-control coating on the surface is glued, laminated, hot-pressed, stretched, dipped and cured to obtain a honeycomb core material layer ...

Embodiment 1

[0066] (1) Copper and nickel are plated on the surface of carbon fiber filaments by electroless plating, the thickness of the copper plating layer is 2 μm, and the thickness of the nickel layer is 0.5 μm;

[0067] (2) Each bundle containing 1000 carbon fiber filaments is bidirectionally alternately woven into a plain weave bidirectional 1K carbon fiber fabric;

[0068] (3) The carbon fiber fabric in step (2) is impregnated with epoxy resin, and then the multi-layer carbon fiber prepreg is laid on the flat mold by hand lay-up process. After curing and molding, the required first panel and second panel are obtained by demolding , the curing temperature is 130°C, the curing time is 90min, and the thickness of the first panel and the second panel are both 1mm;

[0069] (4) The surface of the panel prepared above is polished, and the temperature control coating is coated on the surface by spraying process. The temperature control coating includes paraffin and SiO with a mass ratio ...

Embodiment 2

[0075] (1) Deposit metal copper on the surface of twill carbon fiber and glass fiber fabric by vacuum evaporation process, the thickness of the metal copper layer is 100nm, and then electroplate metal nickel, the thickness of the metal nickel layer is 2 μm;

[0076] (2) Impregnating metallized carbon fiber fabrics and glass fiber fabrics with polyimide resin, then laying a layer of metallized carbon fiber fabrics and metallized glass fiber fabrics alternately on a flat mold, and then demoulding after vacuum bag pressure curing to obtain For the required first and second panels, the curing temperature is 150°C, the curing time is 90 minutes, and the thickness of the first and second panels are both 1.2mm;

[0077] (3) Both the first panel and the second panel prepared above are subjected to surface grinding treatment, and the surface is coated with a temperature-controlling coating using a scraping process, and the temperature-controlling coating includes a mass ratio of 8:15:55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com