Pile top buttress type retaining wall supporting structure and construction method

A technology of support structure and construction method, which is applied in the direction of basic structure engineering, excavation, construction, etc., can solve problems such as safety cannot be guaranteed, and achieve the effects of good slip resistance, good bearing capacity, and improved support capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments to facilitate the understanding of those skilled in the art.

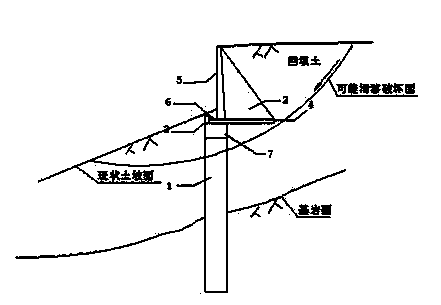

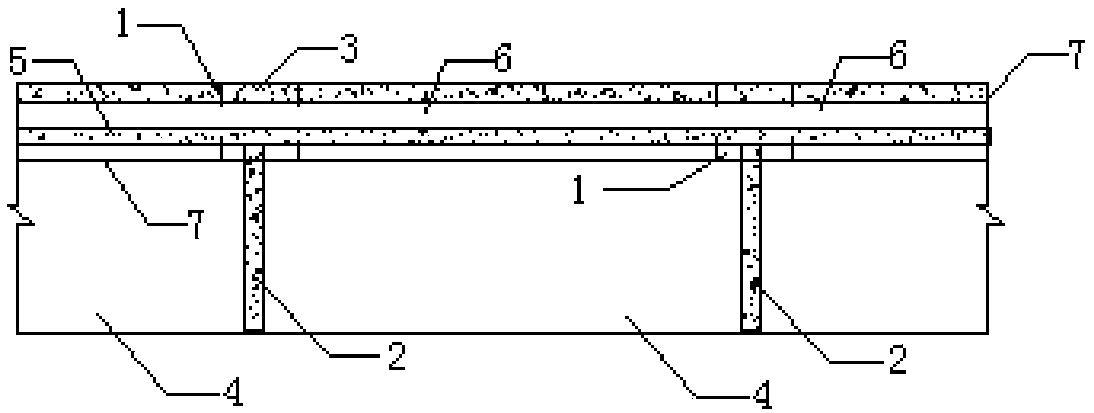

[0023] Figure 1-2 The pile top buttress retaining wall supporting structure shown in the supporting structure includes a pile 1 and a buttress retaining wall. The pile 1 is buried in the soil, and the pile 1 is buried 0.5m below the current soil slope. ~2.0m; the piles 1 are arranged in a straight line, connected by the connecting beam 7, and the connecting beam 7 is connected with the reserved steel bar of the pile 1 through the reinforcement. The buttress-type retaining wall has a height of 4m~15m, including rib 2, heel board 4, wall panel 5 and wall toe board 6, wherein wall panel 5, wall heel board 4, and wall toe board 6 are tied with steel bars The connecting beam 7 is connected by reserved steel bars, the wall panel 5 is perpendicular to the connecting beam 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com