Potassium aspartate compound electrolyte injection and preparation method thereof

A technology of potassium aspartate and compound electrolyte, which is applied in the field of potassium aspartate compound electrolyte injection and preparation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

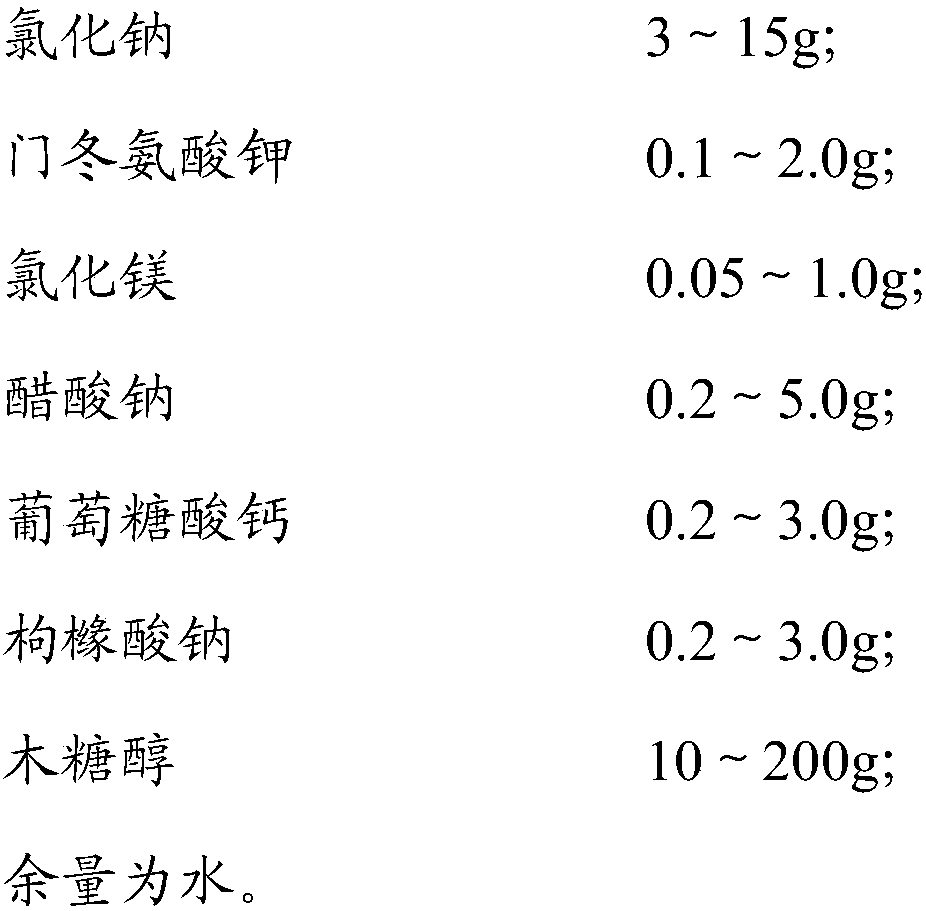

[0046] Composition of prescription:

[0047]

[0048] Preparation:

[0049] (1) Concentration: Place sodium chloride, potassium aspartate, magnesium chloride, sodium acetate, calcium gluconate, sodium citrate and xylitol in a concentration tank according to a predetermined ratio, and add according to the total amount of water for injection 60% water for injection, adjust pH to 7.2, circulate for 20 minutes;

[0050] (2) Pyrogen removal: add activated carbon for injection at 0.5% g / ml, circulate for 20 minutes, filter with 0.45um pore size filter to remove carbon;

[0051] (3) Dilute preparation: pump the concentrated solution into the solution tank, add water for injection to full volume, circulate for 40 minutes, filter with 0.22um pore size filter membrane to obtain filtrate;

[0052] (4) Filling: Filling into a multi-layer co-extrusion infusion bag, each bag is 500ml or 250ml;

[0053] (5) Sterilization: After filling, sterilize at 115°C for 30 minutes to obtain the product.

Embodiment 2

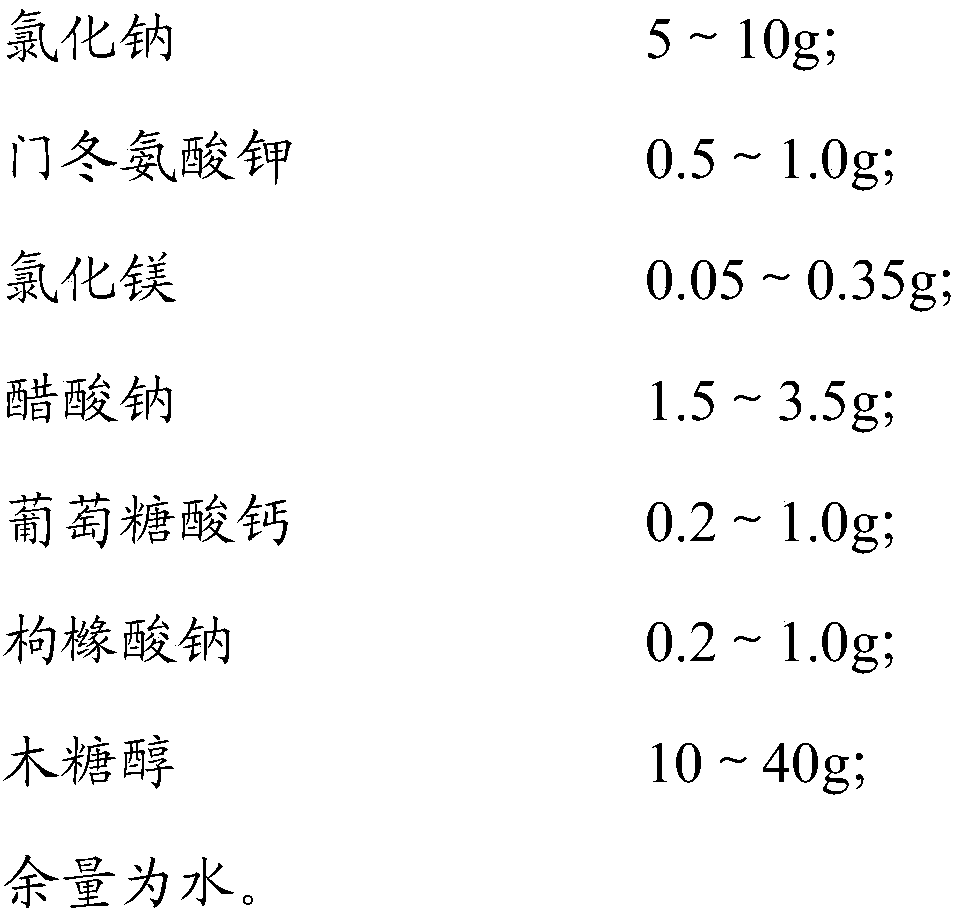

[0055] Composition of prescription:

[0056]

[0057] Preparation:

[0058] (1) Concentration: Place sodium chloride, potassium aspartate, magnesium chloride, sodium acetate, calcium gluconate, sodium citrate and xylitol in a concentration tank according to a predetermined ratio, and add according to the total amount of water for injection 80% water for injection, adjust the pH to 6.7, and circulate for 30 minutes;

[0059] (2) Pyrogen removal: add activated carbon for injection at 0.2% g / ml, circulate for 25 minutes, filter with 0.45um pore size filter to remove carbon;

[0060] (3) Dilute preparation: pump the concentrated solution into the solution tank, add water for injection to full volume, circulate for 30 minutes, filter with 0.22um pore size filter membrane to obtain the filtrate;

[0061] (4) Filling: Filling into a multi-layer co-extrusion infusion bag, each bag is 500ml or 250ml;

[0062] (5) Sterilization: After filling, sterilize at 121°C for 30 minutes to obtain the produ...

Embodiment 3

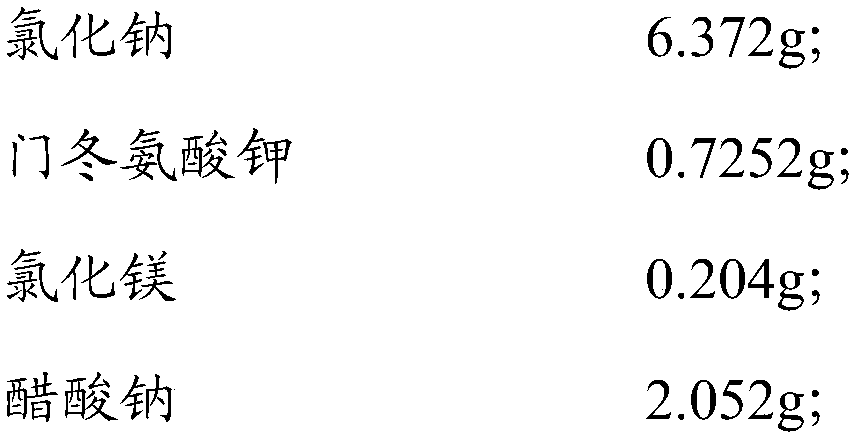

[0064] Composition of prescription:

[0065]

[0066]

[0067] Preparation:

[0068] (1) Concentration: Place sodium chloride, potassium aspartate, magnesium chloride, sodium acetate, calcium gluconate, sodium citrate and xylitol in a concentration tank according to a predetermined ratio, and add according to the total amount of water for injection 40% water for injection, adjust the pH to 4.3, and circulate for 40 minutes;

[0069] (2) Pyrogen removal: add activated carbon for injection at 0.1% g / ml, circulate for 30 min, filter with 0.45um pore size filter to remove carbon;

[0070] (3) Dilute preparation: pump the concentrated solution into the solution tank, add water for injection to full volume, circulate for 30 minutes, filter with 0.22um pore size filter membrane to obtain the filtrate;

[0071] (4) Filling: Filling into a multi-layer co-extrusion infusion bag, each bag is 500ml or 250ml;

[0072] (5) Sterilization: After filling, sterilize at 121°C for 15 minutes to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com