Improved high-molecular cluster pipe cable sleeve

A technology of pipeline lines and polymers, applied in the field of pipeline cable sleeves, can solve the problems of reducing the profitable area of large pipelines, high construction cost, and a lot of increase in construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

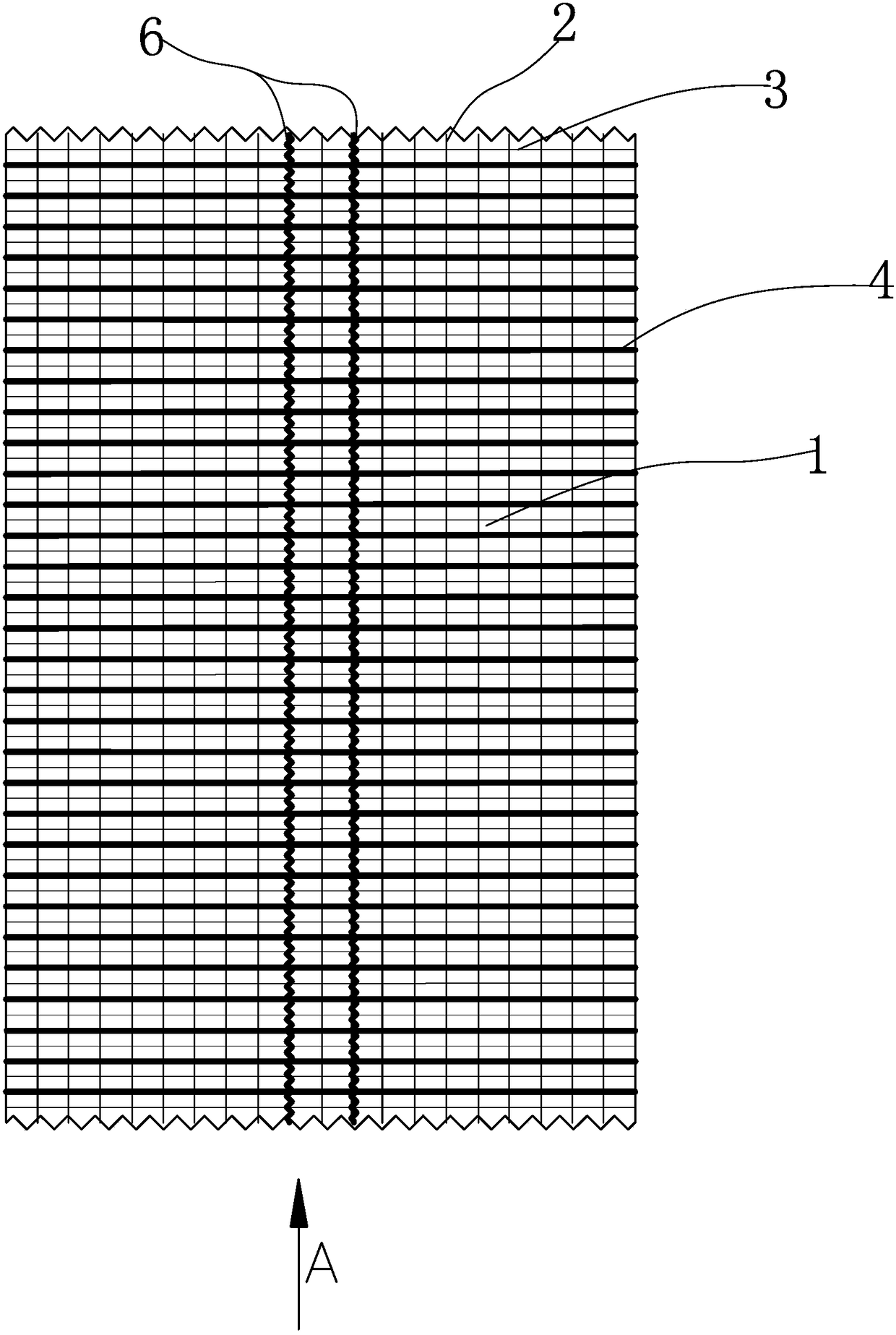

[0017] see figure 1 , a polymer cluster pipeline cable cover, including a cylindrical mesh cover 1 with openings at both ends, the cylindrical mesh cover 1 is surrounded by a mesh sheet, and the mesh sheet is formed by interweaving warp threads 2 and weft threads 3 , The mesh can be in various shapes such as rectangle and rhombus, and the cable sleeve is made into a mesh shape, which can save materials, reduce costs, and reduce weight at the same time. The mesh sheet is made of polymer materials, the selected polymer materials have the characteristics of corrosion resistance, high temperature resistance and wear resistance, such as nylon, PET, etc. In order to make the structure of the cable cover firm, the weft 3 contains a network Silk 4, in the present embodiment: warp thread 2 adopts PET silk, weft thread 3 adopts nylon silk and network silk to arrange at intervals, and the elasticity and strength of PET silk and nylon thread are higher, can guarantee the fastness of cable...

Embodiment 2

[0020] The difference between this embodiment and embodiment 1 is:

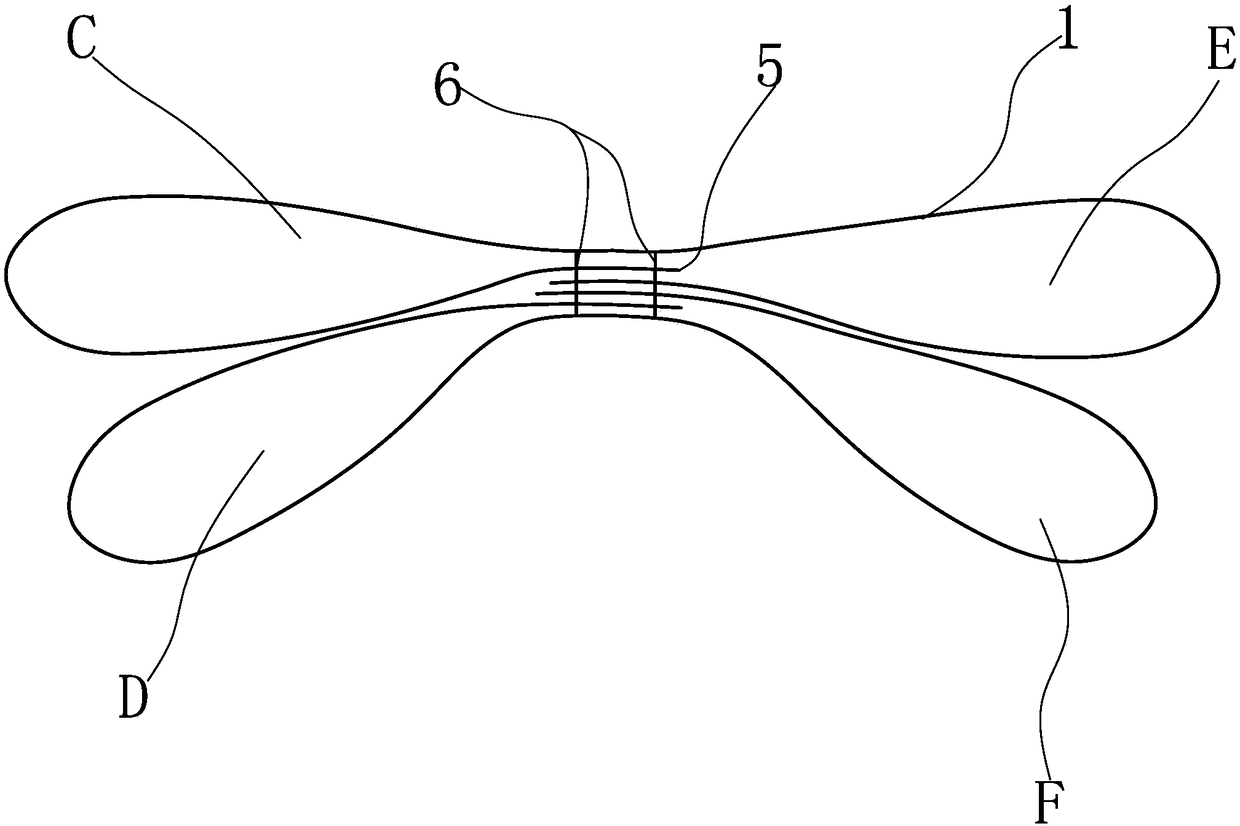

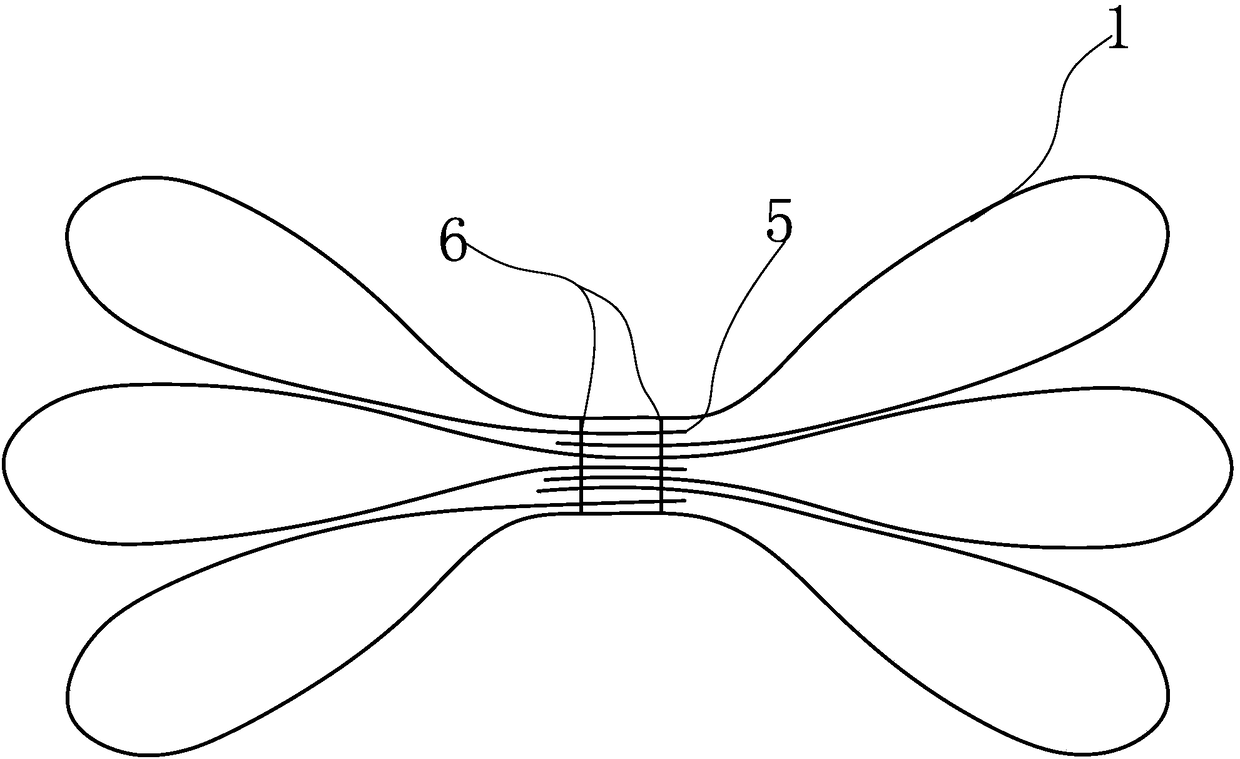

[0021] see Figure 4 and Figure 5 , at least two superimposed mesh covers 1 are sewn together at the edge seam 5 of the mesh sheet, and the suture line 6 is located on one side of the mesh cover, and the outermost mesh sheet wraps the inner mesh cover side seam.

[0022] The cable sleeve made in this way has an increased winding length, the length can be several kilometers or even longer, and it can withstand high temperatures above 220 degrees. It can be folded, and the occupied area is relatively reduced, which improves the utilization rate of the pipeline. After being folded, it can be rolled into a roll, which is very convenient for transportation. In addition, after using polymer materials, the weight of the cable cover 1 is further reduced, and the service life is also longer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com