Battery box system with temperature automatically adjusted

An automatic adjustment and battery box technology, applied in the field of battery box systems, can solve problems such as shortened life, failure to work normally, imperfect fault detection and alarm technology, etc., to achieve the effect of prolonging service life and ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

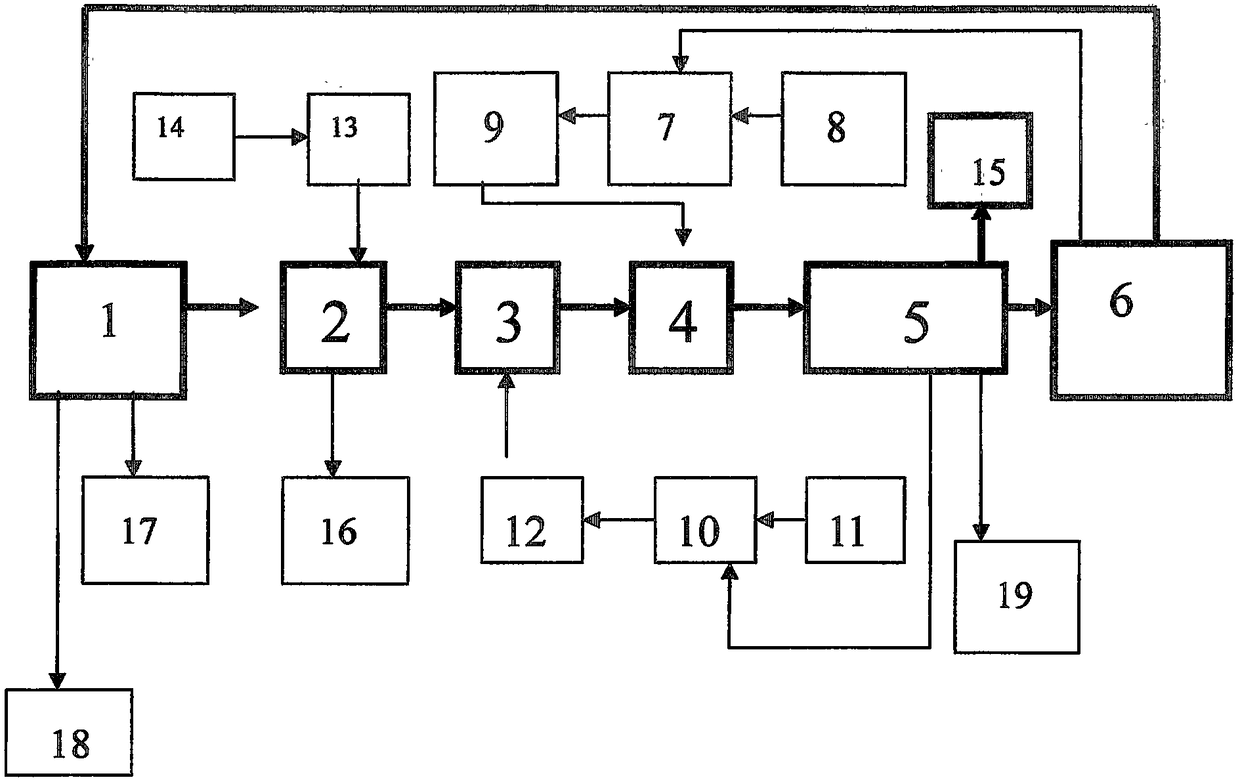

[0022] Such as figure 1 As shown, a closed medium tank 1 that can withstand a certain pressure is connected to a medium pump 2 through a pipe. The medium pump 2 is connected to a heat exchanger 3 through a pipe. The heat exchanger 3 is connected to a splitter 4 through a pipe. The splitter 4 is connected through a pipe. Connected to the battery box 5, the battery box 5 is connected to the current collector 6 through a pipe, and the current collector 6 is connected to the medium box 1 through the pipe; the medium pump 2 is connected to the medium pump controller 13 through a wire, and the medium pump controller 13 is connected to the medium The pump power supply 14 is connected; the heat exchanger 3 is connected in series in the medium circuit, the medium in the medium tank 1 passes through the flow passage of the heat exchanger 3, and the flow passage of the heat exchanger 3 is connected to the air outlet of the fan 12, and the power supply of the fan 12 The wire is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com