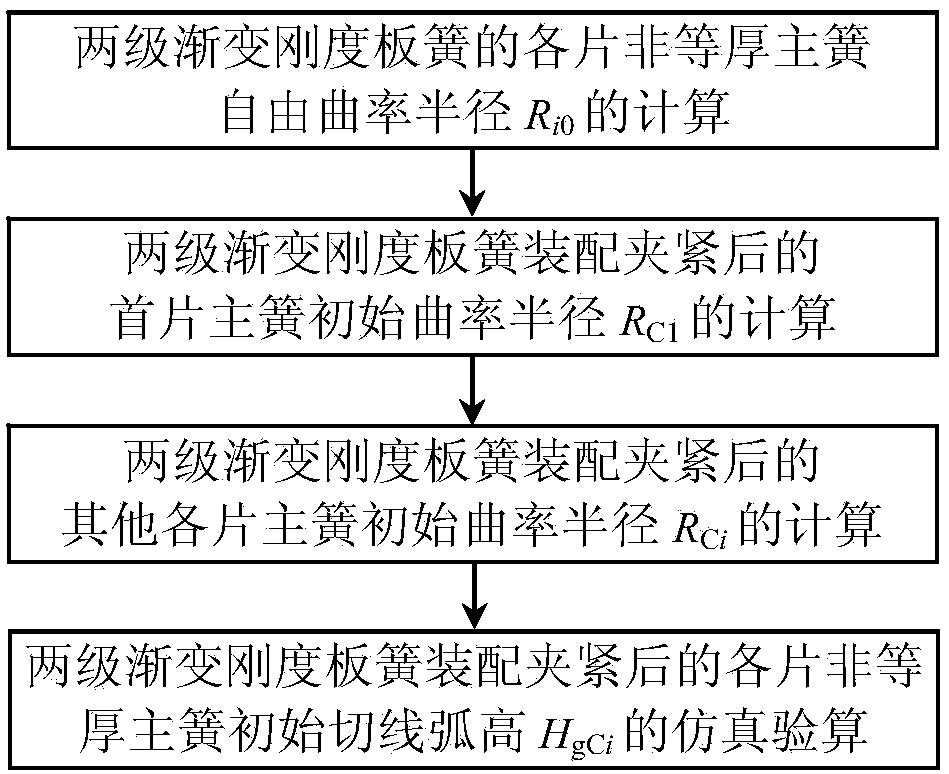

Simulation calculation method for initial tangent arc heights of unequally-thick main springs of two-stage gradual-rigidity leaf springs

A technology of non-uniform thickness and leaf springs, which is applied in the field of simulation algorithm of the initial tangent arc height of thick main springs, can solve the problem that accurate and reliable two-stage gradient stiffness leaf springs with non-uniform thickness main springs cannot be satisfied. Gradient rigidity plate springs and other problems, to reduce design and test costs, improve design level, speed up the effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

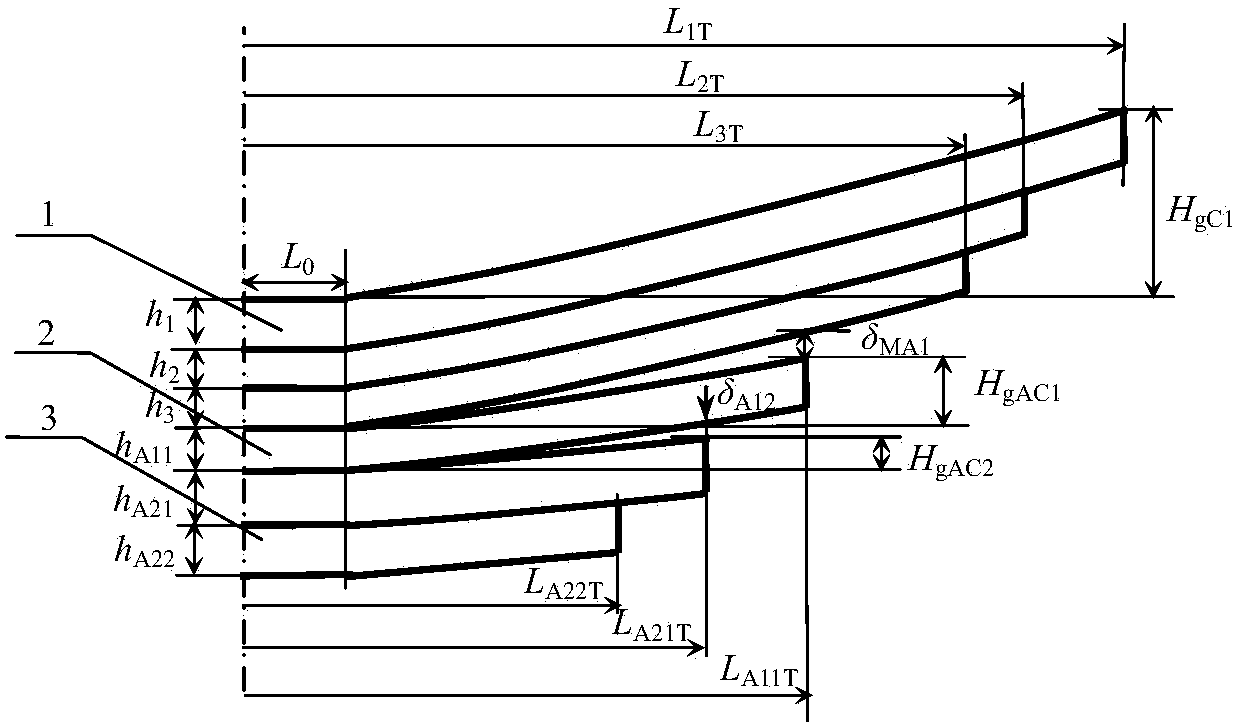

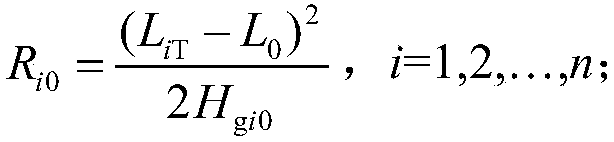

Embodiment 1

[0025] Embodiment 1, the width b=60mm of a certain two-stage gradient stiffness leaf spring, the thickness of each main spring is not equal, that is, the non-equal thickness superimposed main spring, half the length L of the straight section of the root 0 = 50mm. The number of main reeds is n=3, and the thickness of each main spring is h 1 = 9mm, h 2 = h 3 =8mm, half of the active length of each main spring is L 1T =525mm,L 2T =450mm, L 3T =350mm, the design value of the free tangent arc height of each main spring is H g10 =94.9mm,H g20 =70.4mm, H g30 = 42.2 mm. The number of sheets of the first secondary spring m 1 = 1 piece, the leaf spring thickness h of the first secondary spring A11 =13mm, the working length of half of the first secondary spring is L A11T =250mm. The number of pieces of secondary secondary spring m 2 =1, the leaf spring thickness h of the secondary secondary spring A21 =13mm, half the working length of the secondary secondary spring is L A2...

Embodiment 2

[0046] Embodiment 2, the width b=63mm of a certain two-stage gradient stiffness leaf spring, the thickness of each main spring is not equal, that is, the main spring is superimposed with non-equal thickness, half the length L of the straight section of the root clamped by the saddle bolt 0 = 55mm. The number of main reeds n=2 pieces, the thickness h of each main spring 1 = 10mm, h 2 =9mm, half of the active length of each main spring is L 1T =525mm,L 2T = 450mm, the design value of the free tangent arc height of each main spring is H g10 =90.0mm, H g20 =71.6mm. The number of sheets of the first secondary spring m 1 = 1 piece, the thickness h of the first secondary spring A11 = h 4 =13mm, the working length of half of the first secondary spring is L A11T =250mm. The number of pieces of secondary secondary spring m 2 = 1, the thickness h of the secondary secondary spring A21 =13mm, half the working length of the secondary secondary spring is L A21T = 150mm. Accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com