Lens module and assembling method of lens module

A switcher and filter technology, applied in the direction of instruments, optics, optical components, etc., can solve the problems of focus forward, expansion, imaging blur, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

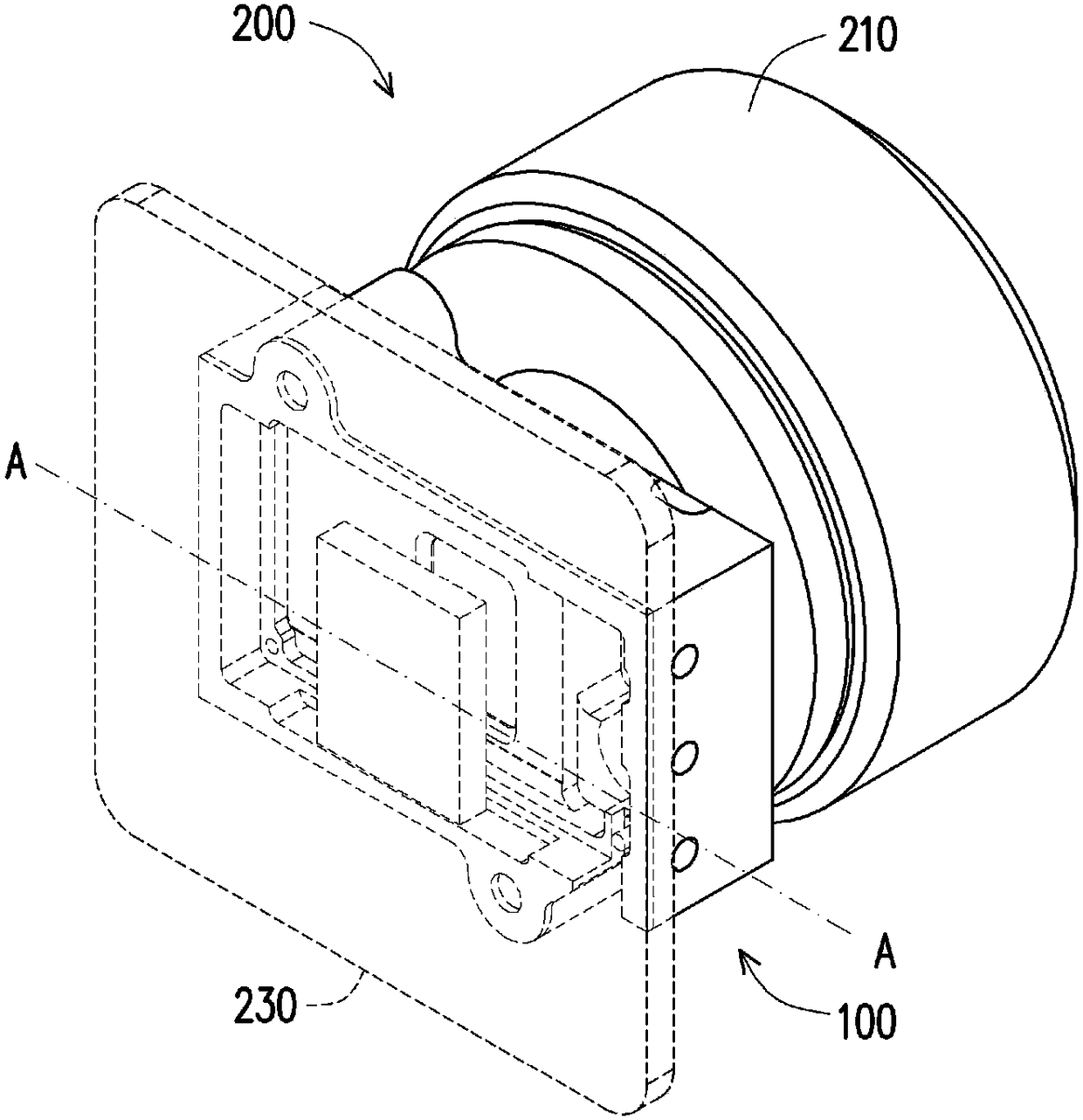

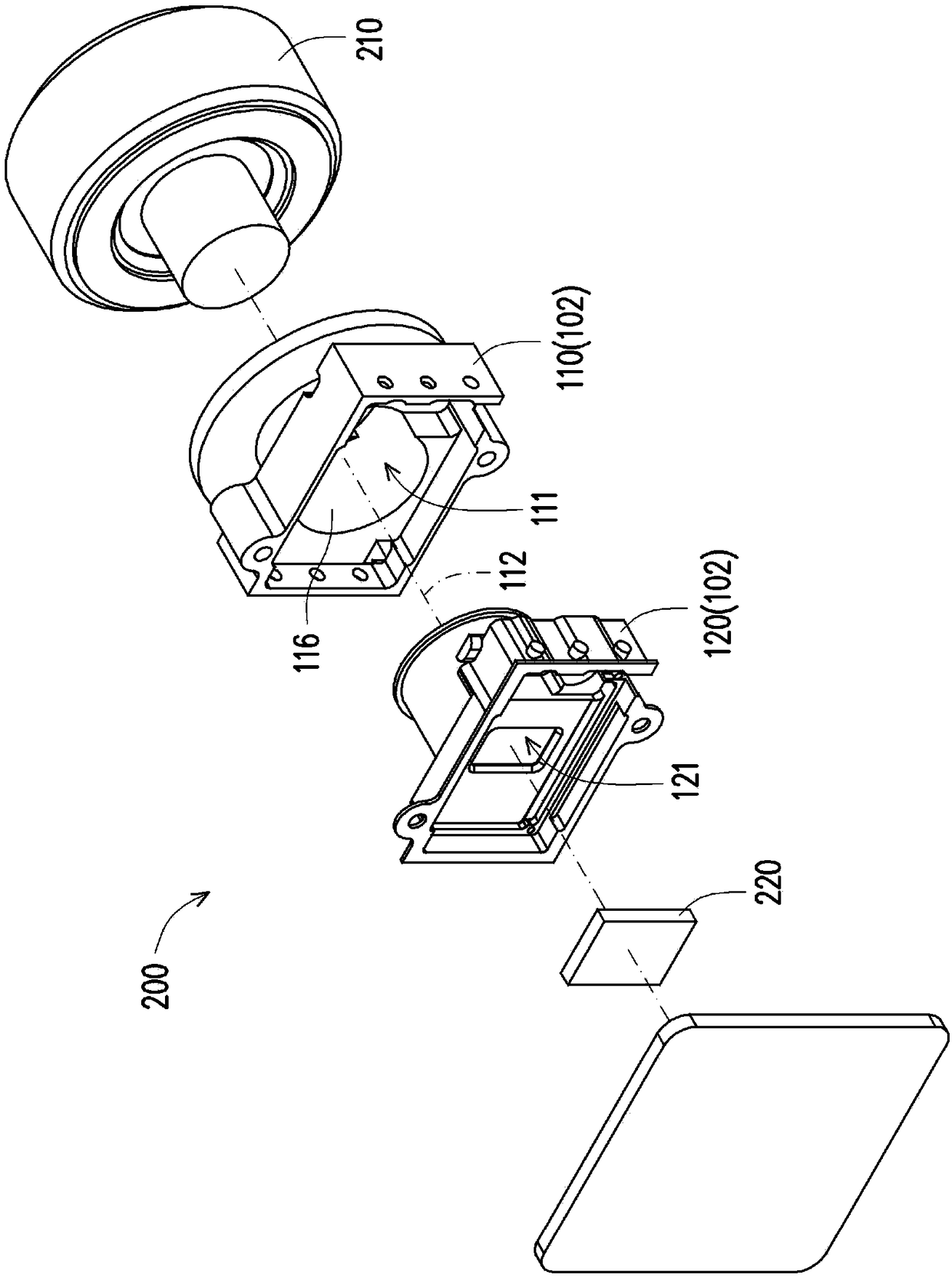

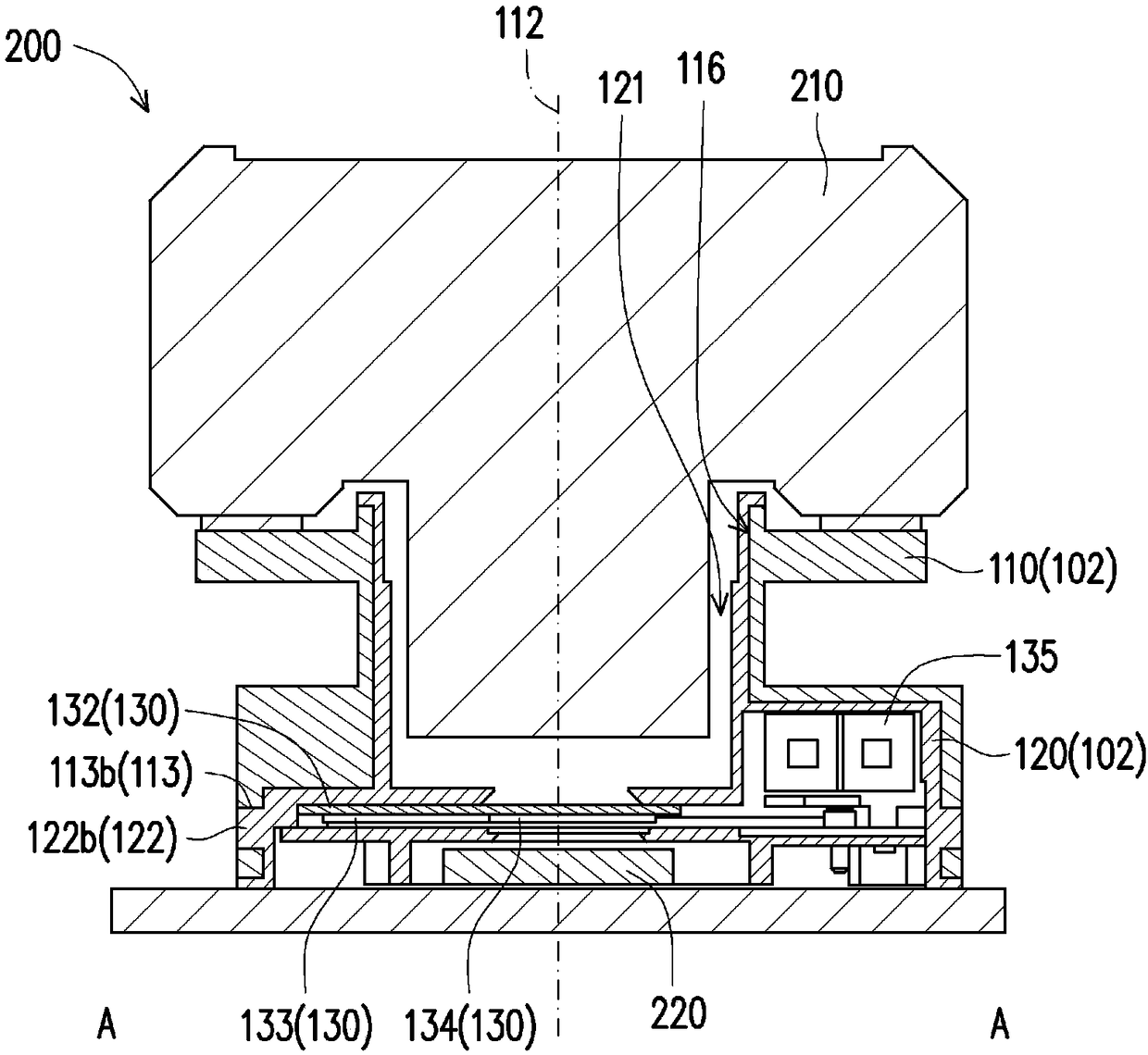

[0057] figure 1 It is a schematic diagram of an embodiment of the present invention in which the lens integrates and hides the filter switcher. figure 2 yes figure 1 exploded view of the lens integration. image 3 yes figure 1 A sectional view of the lens integration along section line A-A. figure 1 The circuit board 230 is shown in dotted lines, and structures obscured by the circuit board 230 are shown in dotted lines. For clean lines, figure 1 and figure 2 A filter switcher 130 is hidden in the middle. image 3 It is shown that the filter switcher 130 is disposed in the second housing 120 . Please refer to Figure 1 to Figure 3 , the lens integration 200 includes a filter switcher module 100, a lens 210 disposed on one side of the filter switcher module 100, and an image sensor 220 and a circuit board 230 disposed on the other side of the filter switcher module 100, and The image sensor 220 is located at the focal point of the lens 210 and is electrically connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com