Rockburst danger-relieving method based on hydraulic mechanical splitting

A technology of hydraulic machinery and rockburst, applied in the field of mining and geotechnical engineering safety prevention and control, can solve the problems of unavoidable strength of rockburst, difficult to guarantee cracking effect, and difficult to control strong rockburst, etc. The effect of rock integrity and rockburst tendency, intuitive and controllable splitting effect, and low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

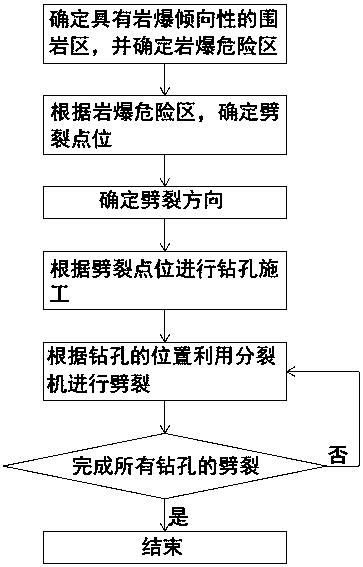

[0026] figure 1 It is the best embodiment of the present invention, below in conjunction with attached figure 1 The present invention will be further described.

[0027] Such as figure 1 As shown, a rockburst hazard relief method based on hydraulic mechanical splitting includes the following steps:

[0028] Step 1, determine the surrounding rock area with rockburst tendency, and determine the rockburst dangerous area;

[0029] Determine the surrounding rock area with rockburst tendency, delineate the high stress area of the surrounding rock, and determine the rockburst dangerous area.

[0030] Step 2, determine the splitting point according to the rockburst danger zone;

[0031] According to the hazard level of the rockburst hazard area, the splitting point is determined on the surrounding rock.

[0032] When determining the splitting point, the splitting point can be arranged in a square or quincunx shape, and the distance between the splitting points increases sequent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com