High-strength and high-toughness plastic building formwork

A technology for building formwork and tough plastic, applied in the field of construction equipment, can solve the problems of poor toughness, single function, poor flame retardancy of building formwork, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

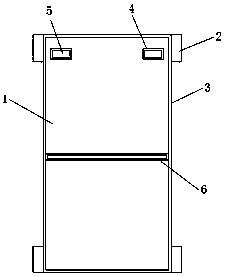

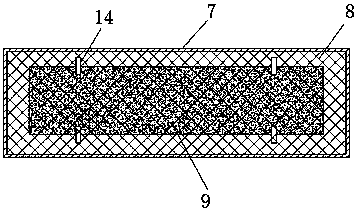

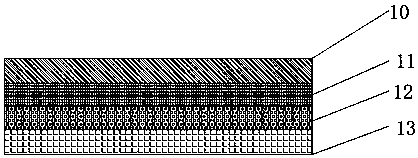

[0020] See Figure 1-3 , The present invention provides a technical solution: a high-strength and high-toughness plastic construction template, including a plastic template body 1, the plastic template body 1 is configured as a square structure as a whole, and the four corners of the plastic template body 1 There is a connecting convex column 2, the outer side of the plastic template body 1 is provided with a square convex ring 3, the top of the plastic template body 1 is provided with two square groove columns 4 symmetrically on the left and right sides, and the inner side of the square groove column 4 A square groove 5 is provided, and the middle position of the plastic template body 1 is provided with a strip-shaped convex column groove 6; the plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com