Post-grouting precast hollow pipe root pile structure and construction method

A technology of hollow tubes and tree root piles, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of complex construction and long construction period, and achieve the effect of protecting integrity and maintaining verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

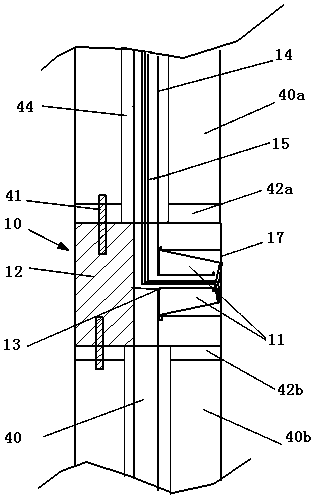

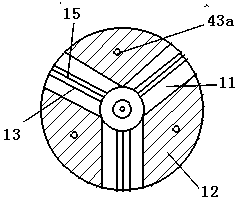

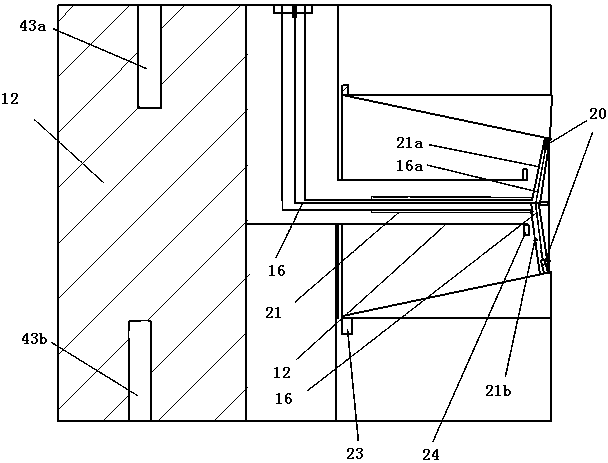

[0037] A post-grouting prefabricated tubular stump structure, figure 1 It is a schematic diagram of the longitudinal section of the prefabricated hollow tubular body along the left and right direction. figure 2 is a schematic diagram of the cross-sectional structure of the upper part of the connector 10 . The post-grouting prefabricated pipe stump structure includes a prefabricated hollow pipe and a connecting pin 41 at the butt joint of the prefabricated hollow pipe. A grout pouring pipe 14 is arranged inside the prefabricated hollow pipe, and a conduit 15 is arranged therebetween. The electric wire 16 runs through the conduit 15. The prefabricated hollow pipe The pipe butt joint part is provided with a connector 10, and the middle of the connector 10 is provided with a grout pouring pipe 14, a conduit, an electric wire and an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com