Wear-resisting winding apparatus

A wear-resistant and yarn-winding technology, used in textiles and papermaking, looms, textiles, etc., can solve the problem of large damage to the weft, and achieve the effect of solving the large damage, enhancing the anti-wear ability and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

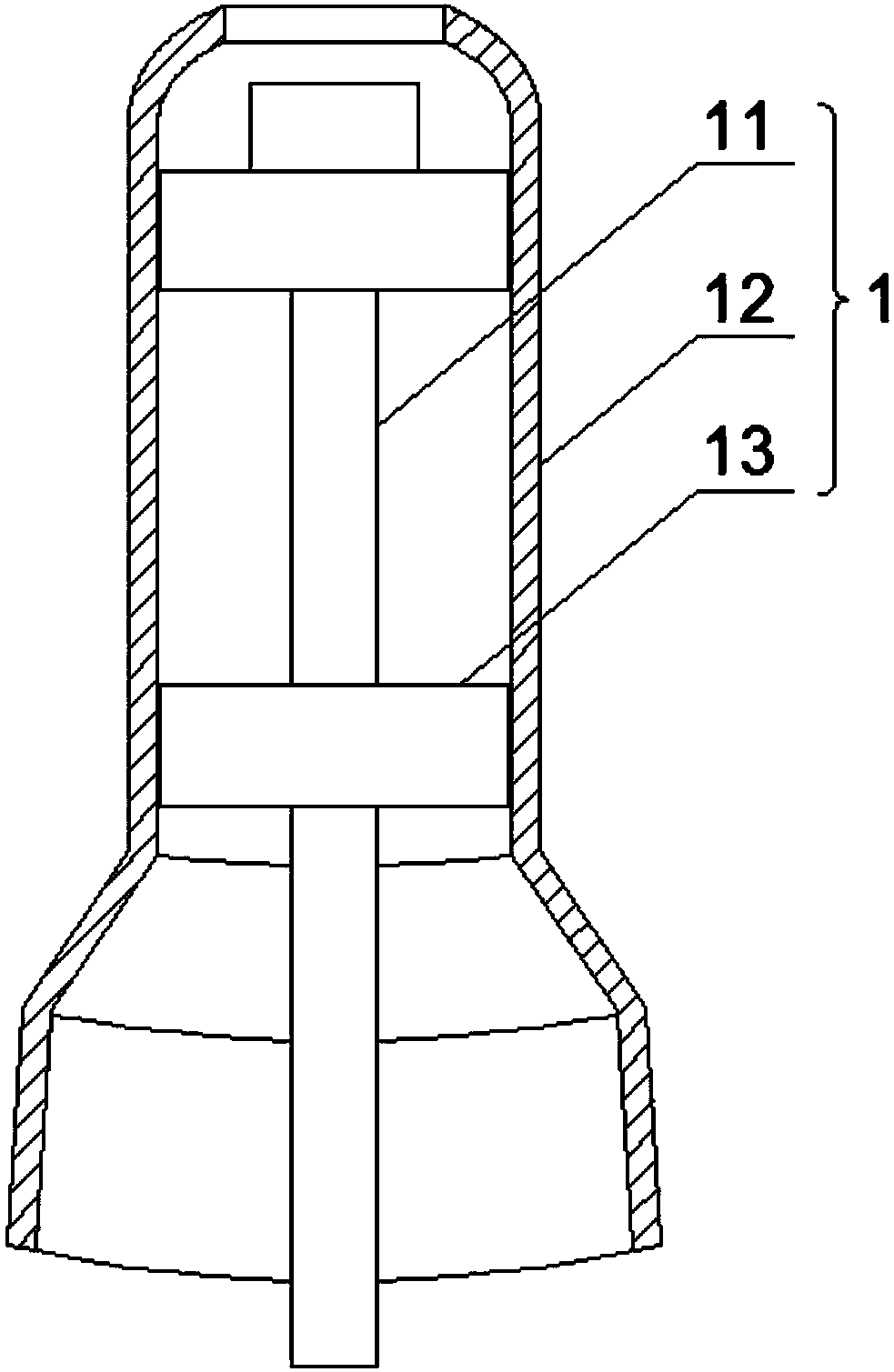

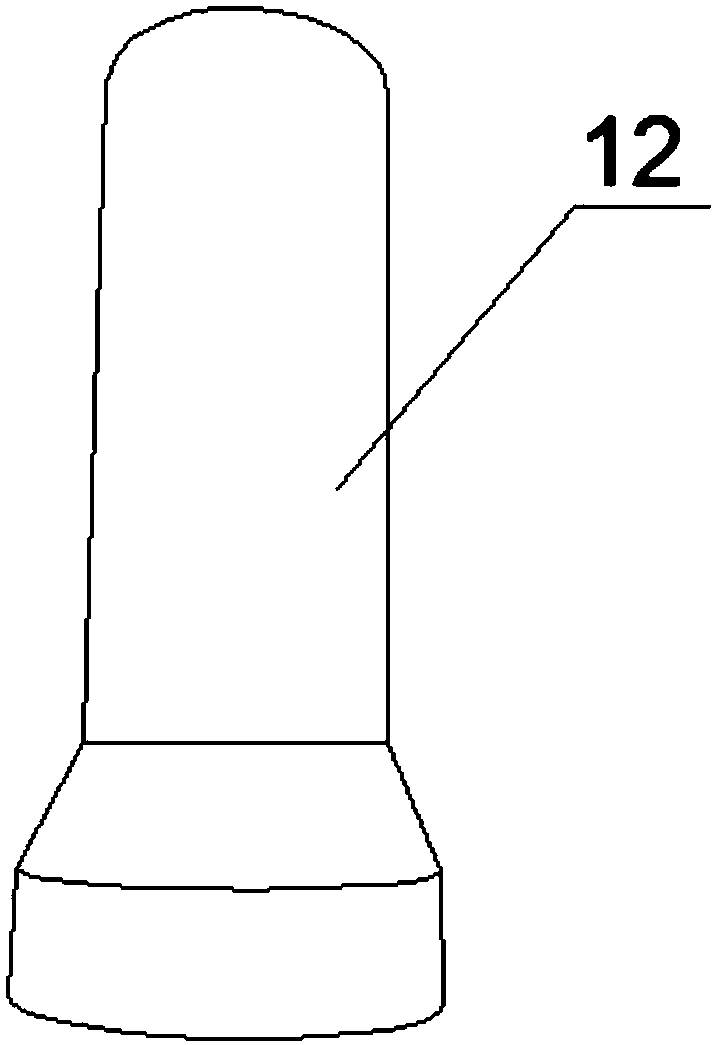

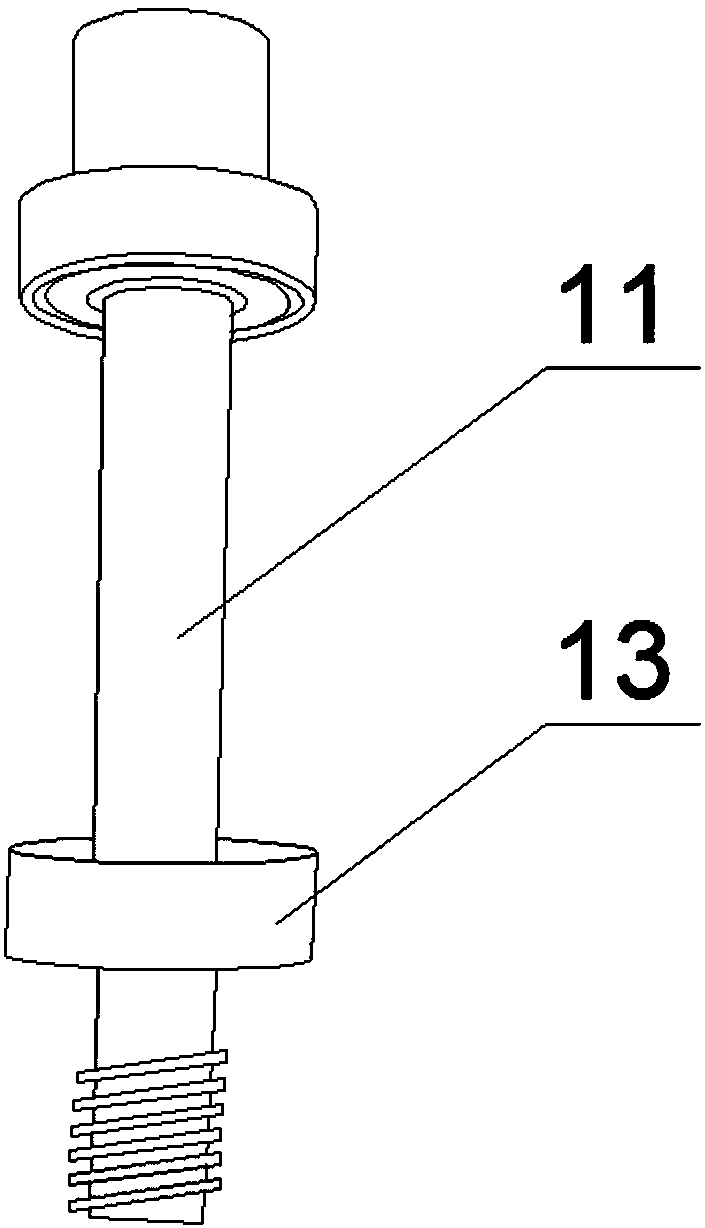

[0038] In the optional scheme of this embodiment, such as Figure 1 to Figure 4 As shown, an anti-abrasion yarn winding device provided in this embodiment includes a yarn winding disk 2 and six winding guide rollers 1; the six yarn winding guide rollers 1 are arranged on the yarn winding disk 2 along the 2; the winding guide roller 1 includes a guide roller shaft 11 and a guide roller sleeve 12; the guide roller sleeve 12 is movably sleeved on the guide roller shaft 11, and the guide roller sleeve 12 can rotate around the axis of the guide roller shaft 11; the guide roller sleeve 12 includes an anti-wear layer.

[0039] In this embodiment, six yarn winding guide rollers 1 are evenly distributed on the yarn winding disk 2 in a ring shape, and the connecting lines form a regular hexagon to wind yarn together; the guide roller sleeve 12 is movably sleeved on the guide roller shaft 11 , the guide roller sleeve 12 can rotate with a fixed axis relative to the guide roller shaft 11....

Embodiment 2

[0065] In the optional solution of this embodiment, an anti-abrasion yarn winding device provided by this embodiment includes a yarn winding disk 2 and four winding guide rollers 1; Circumferentially arranged on the yarn winding disc 2; the yarn winding guide roller 1 includes a guide roller shaft 11 and a guide roller sleeve 12; The axis rotates; the guide roller sleeve 12 includes an anti-wear layer.

[0066] In this embodiment, four yarn winding guide rollers 1 are evenly distributed in a ring shape on the yarn winding disk 2, and the connecting lines form a square, and the yarn is wound together; the guide roller sleeve 12 is movably sleeved on the guide roller shaft 11, and The roller cover 12 can rotate with a fixed axis relative to the guide roller shaft 11. When the yarn is wound or unwound, the guide roller cover 12 can rotate together with the movement of the weft yarn, which reduces the friction on the weft yarn and also reduces the tension of the weft yarn , the d...

Embodiment 3

[0072] In the optional solution of this embodiment, an anti-abrasion yarn winding device provided by this embodiment includes a yarn winding disk 2 and two winding guide rollers 1; Circumferentially arranged on the yarn winding disc 2; the yarn winding guide roller 1 includes a guide roller shaft 11 and a guide roller sleeve 12; The axis rotates; the guide roller sleeve 12 includes an anti-wear layer.

[0073] In this embodiment, two yarn winding guide rollers 1 are parallel to form a yarn winding plane for yarn winding; the guide roller sleeve 12 is movably sleeved on the guide roller shaft 11, and the guide roller sleeve 12 can be positioned relative to the guide roller shaft 11 Fixed axis rotation, when winding or unwinding, the guide roller sleeve 12 can rotate together with the movement of the weft yarn, which reduces the friction on the weft yarn, and also reduces the tension of the weft yarn, and the damage to the weft yarn is small. The cloth is flat and evenly colore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com