Method and system for forecasting local anode effect in aluminum electrolytic bath

An anode effect, aluminum electrolytic cell technology, applied in the field of aluminum electrolysis, can solve the problems of inability to eliminate the effect in "sprouting, unable to detect local anode effect in time, and achieve the effect of reducing the occurrence of global anode effect and accurate forecasting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Such as figure 1 As shown, the present invention provides a method for predicting the local anode effect of an aluminum electrolytic cell comprising the following steps:

[0047] Step 1: Collect the anode current of each anode block in the aluminum electrolytic cell at the sampling point in the first time window, and select the anode current at the corresponding sampling point in the second time window from the collected anode current in the first time window ;

[0048] Wherein, the first time window of the first preset duration is selected forward with the t moment as the end point, and the second time window of the second preset duration is selected in the first time window, and the end point of the second time window is t time and the first preset duration is longer than the second preset duration, time t is the time to be measured; the first time window and the second time window both use time t as the end point of the time window and have different starting points...

Embodiment 2

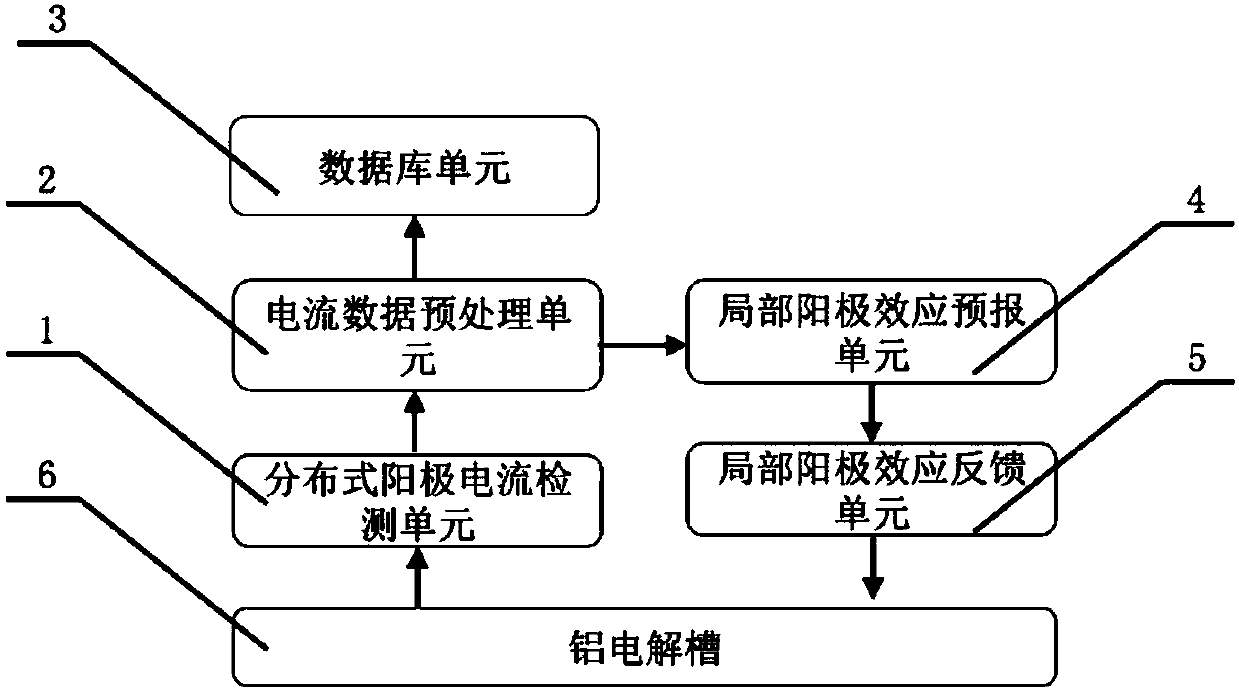

[0060] Such as figure 2 with image 3 As shown, the present invention provides a local anode effect forecasting system for an aluminum electrolytic cell, which adopts a distributed collection method to collect the anode current of the anode block. Specifically, the forecast system includes: a distributed anode current detection unit 1 , a current data preprocessing unit 2 , a local anode effect forecast unit 4 , a database unit 3 and a local anode effect feedback unit 5 .

[0061] Among them, the distributed anode current detection unit 1 is used to collect the anode current on each anode block in the aluminum electrolytic cell. Specifically, the distributed anode current detection unit 1 includes several detection elements, and each anode block is provided with a detection element . The distributed anode current detection unit 1 is connected to the current data preprocessing unit 2 , and the distributed anode current detection unit 1 sends the collected anode current to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com