Integrated stamping forming process for attached plate of film clamping chain

A technology of stamping forming and external attachment plate, applied in the field of sandwich chain, can solve the problems of occupying a lot of equipment, reducing stamping forming accuracy, reducing the quality of parts, etc., to shorten the product processing process, ensure stamping stability, and ensure dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to facilitate the understanding of the present invention, the present invention will be described in detail below with reference to the preferred embodiments of the present invention given in the drawings.

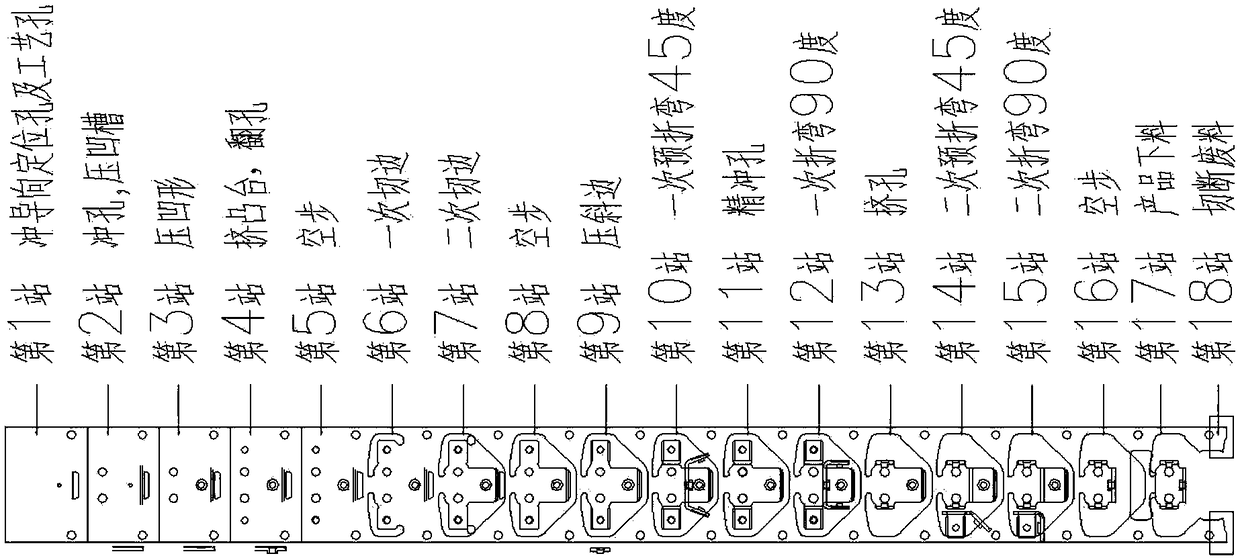

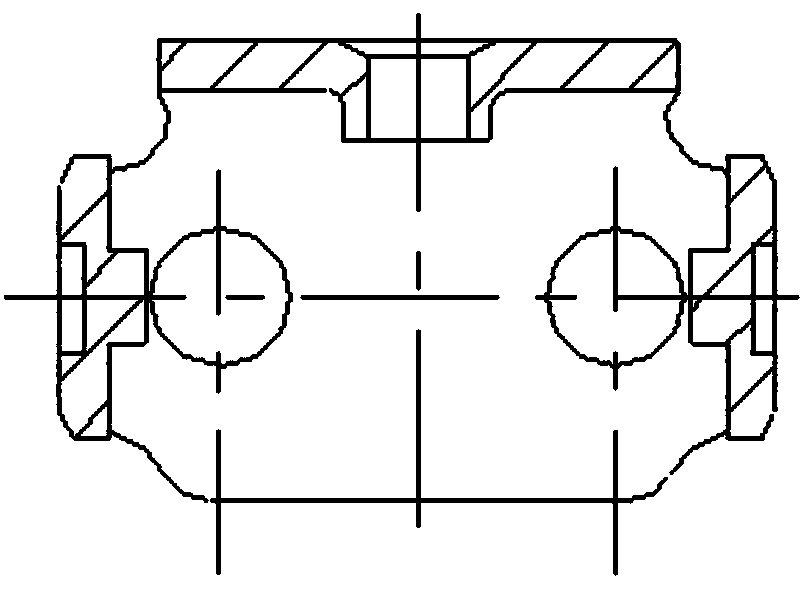

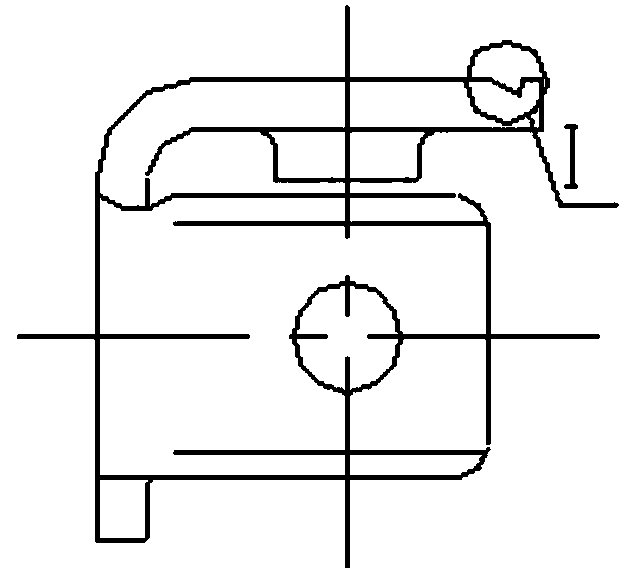

[0045] See Figure 1 to Figure 5 In an embodiment of the present invention, an integrated stamping and forming process for the outer attachment plate of a sandwich film chain. During the automatic feeding process of the steel belt, the outer attachment plate parts are combined with the steel belt through an intermediate carrier, and the continuous die is used to automatically and continuously complete the outer attachment on the punching machine. In the plate stamping forming process, a stamping forming processing line is set on the continuous die, and the automatic feeding mechanism on the stamping forming processing line continuously advances and sequentially realizes the following processing steps:

[0046] a. Punching guide positioning holes and process hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com