Method for producing a work piece through generative manufacturing, and corresponding work piece

A generative manufacturing, workpiece technology, applied in the field of manufacturing workpieces, workpieces or components, can solve the problems of limiting additive production and difficult manufacturing, and achieve the effect of improving resolution and improving production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

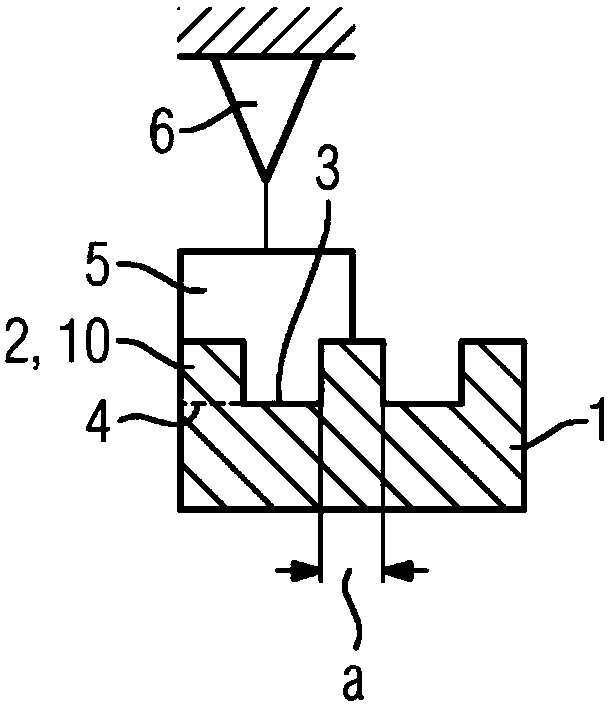

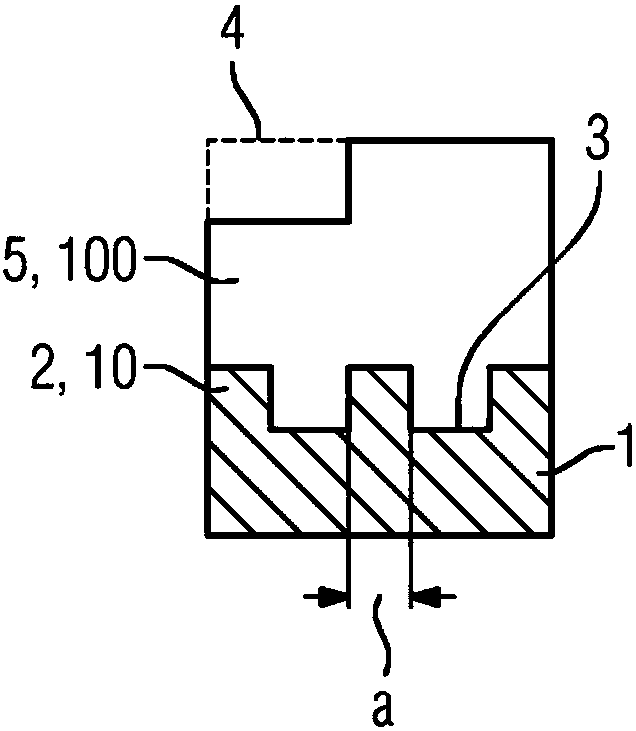

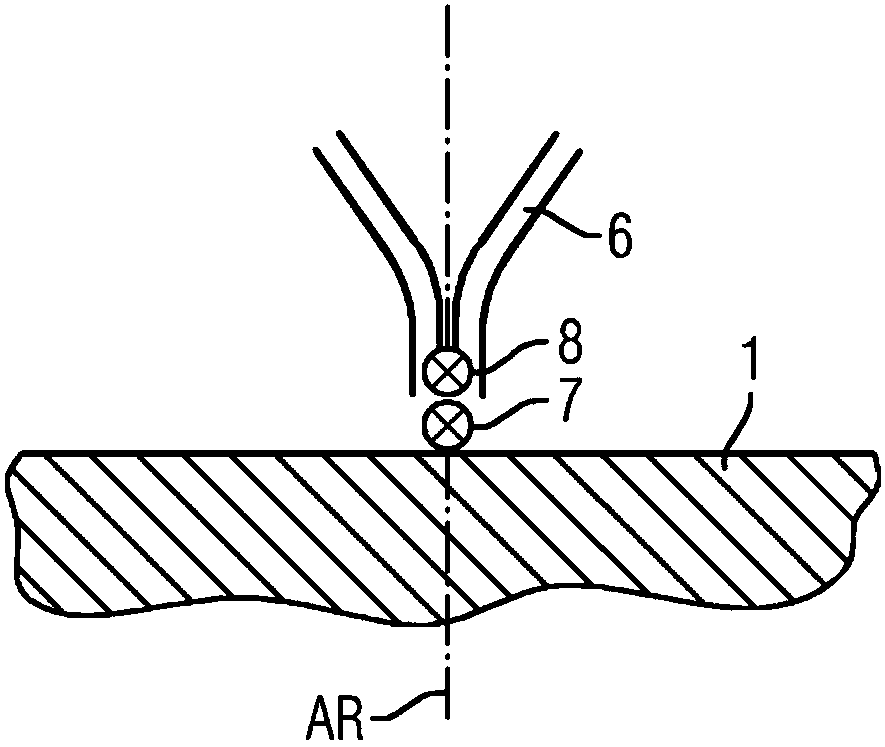

[0043] figure 1 Schematically shown for the manufacture of workpieces or components (see figure 2 Reference numeral 100 in ), for example a sequence of a method for a component of a fluid machine, such as a gas turbine. The workpiece 100 is preferably a high temperature resistant workpiece for use in connection with the hot air path of a gas turbine. The workpiece or component preferably consists of a nickel-based or cobalt-based superalloy or contains corresponding materials.

[0044] The method includes: providing a substrate 1, the substrate is in figure 1 or figure 2 Shown in side view or cross-sectional view. The substrate 1 comprises a predetermined surface structure 2 . The predetermined surface structure 2 is preferably a surface structure with surface structure units 10, as in figure 1 and 2 as indicated in. The surface structure units 10 each have a rectangular cross section. The surface structure units 10 are preferably microscopically small. In other wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com