PCB quick plate-making machine with parallel structure

A plate making machine, parallel technology, applied in the direction of printed circuit manufacturing, electrical components, printed circuits, etc., can solve problems such as large relative position error between pad and scribe line, disconnection or connection between lines, accumulated motion error, etc. Improve efficiency and quality, no cumulative error, fast movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

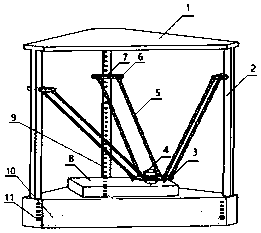

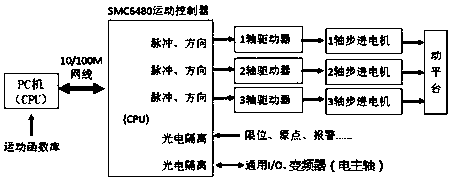

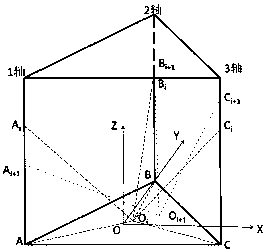

[0023] A parallel structure PCB rapid plate-making machine, frame, workbench, moving platform, slider, synchronous belt and motor, the described workbench is set on the platform of the frame, the number of the synchronous belts is 3, the 3 The three synchronous belts are respectively arranged on the frame through pulleys, and the three synchronous belts are respectively connected with the motor, that is, one synchronous belt is connected with one motor, and is driven by the motor to rotate, and the three synchronous belts are respectively connected with the workbench Vertically, the three synchronous belts are distributed on the frame in a triangular structure, and the sliders are three, and the three sliders are respectively fixed on the synchronous belt, and each slider is fixed on one synchronous belt , the moving platform is connected to the three sliders through connecting rods, and the connecting rods are respectively connected to the sliding blocks and the moving platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com