Thread screw joint structure

A threaded screw and structure technology, applied in the field of screw thread structure, can solve the problems of difficulty in reducing labor and time costs, high cost, loosening, etc., to improve the convenience and efficiency of assembly, reduce labor and time costs, and improve screw The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

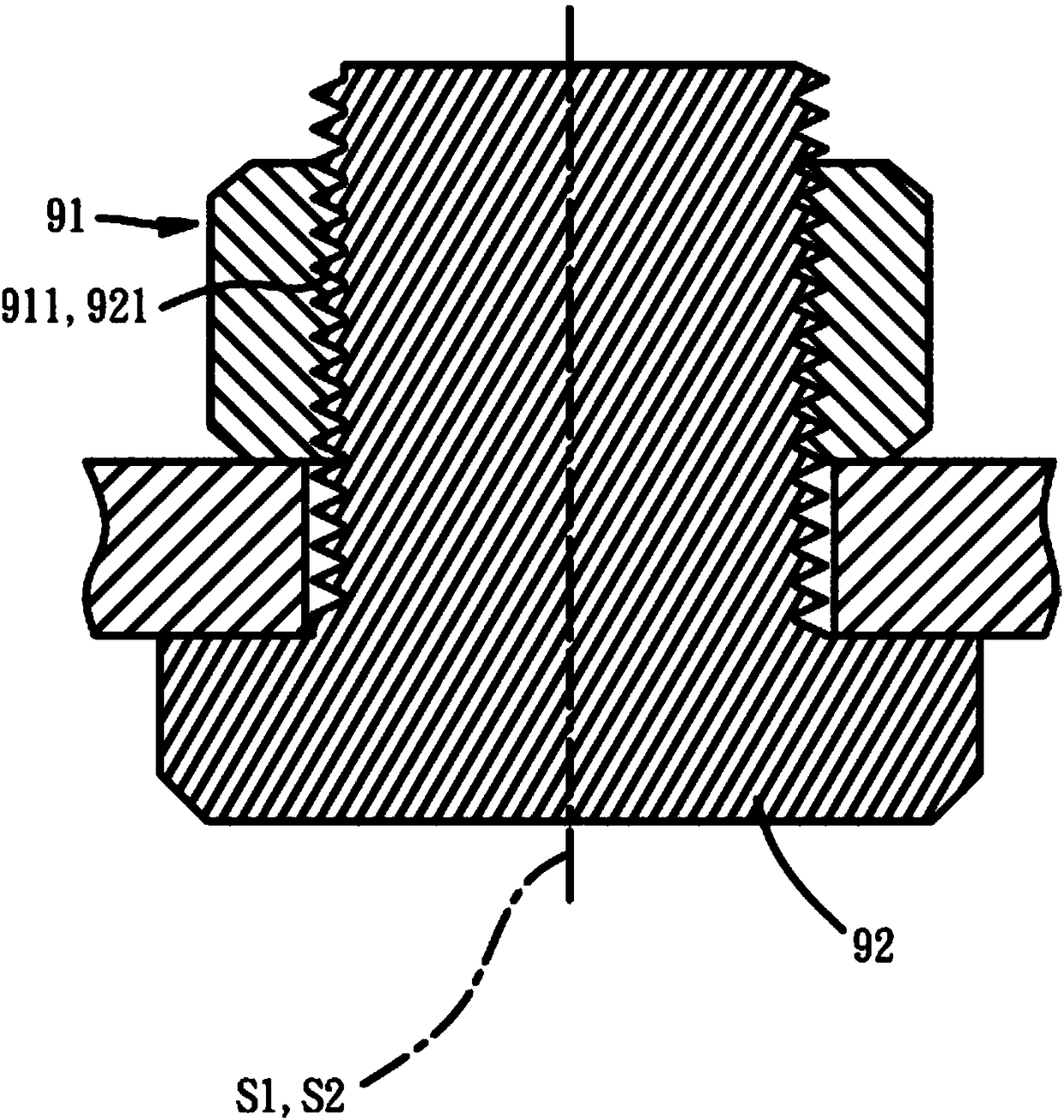

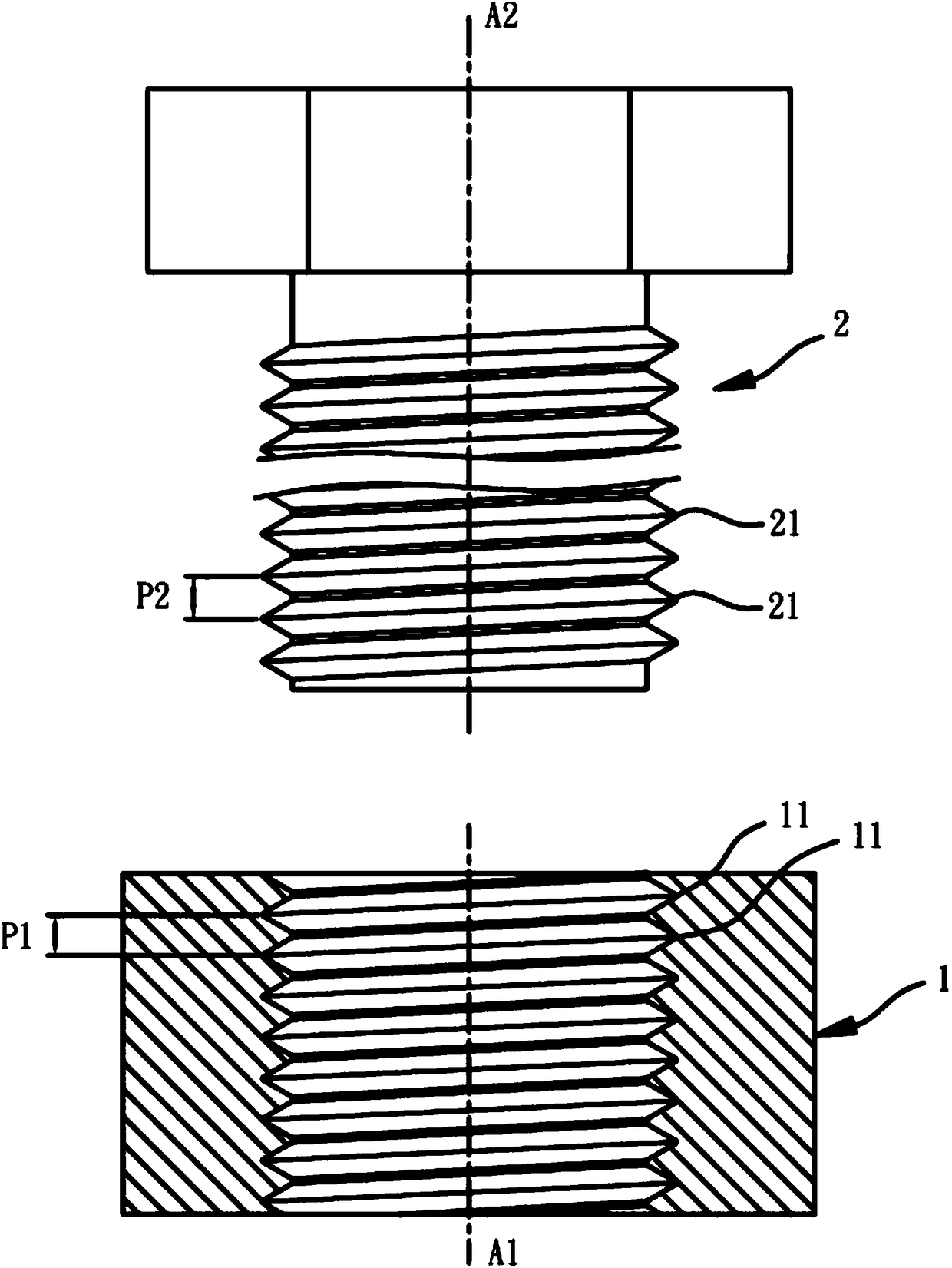

[0044] Please refer to Figure 4 , Which is the second embodiment of the threaded screw structure of the present invention. The main difference between the second embodiment of the present invention and the above-mentioned first embodiment is: in addition to the aforementioned pitch difference, the second embodiment of the present invention also makes the internal thread 11 and the external thread 21 has a slight thread height difference.

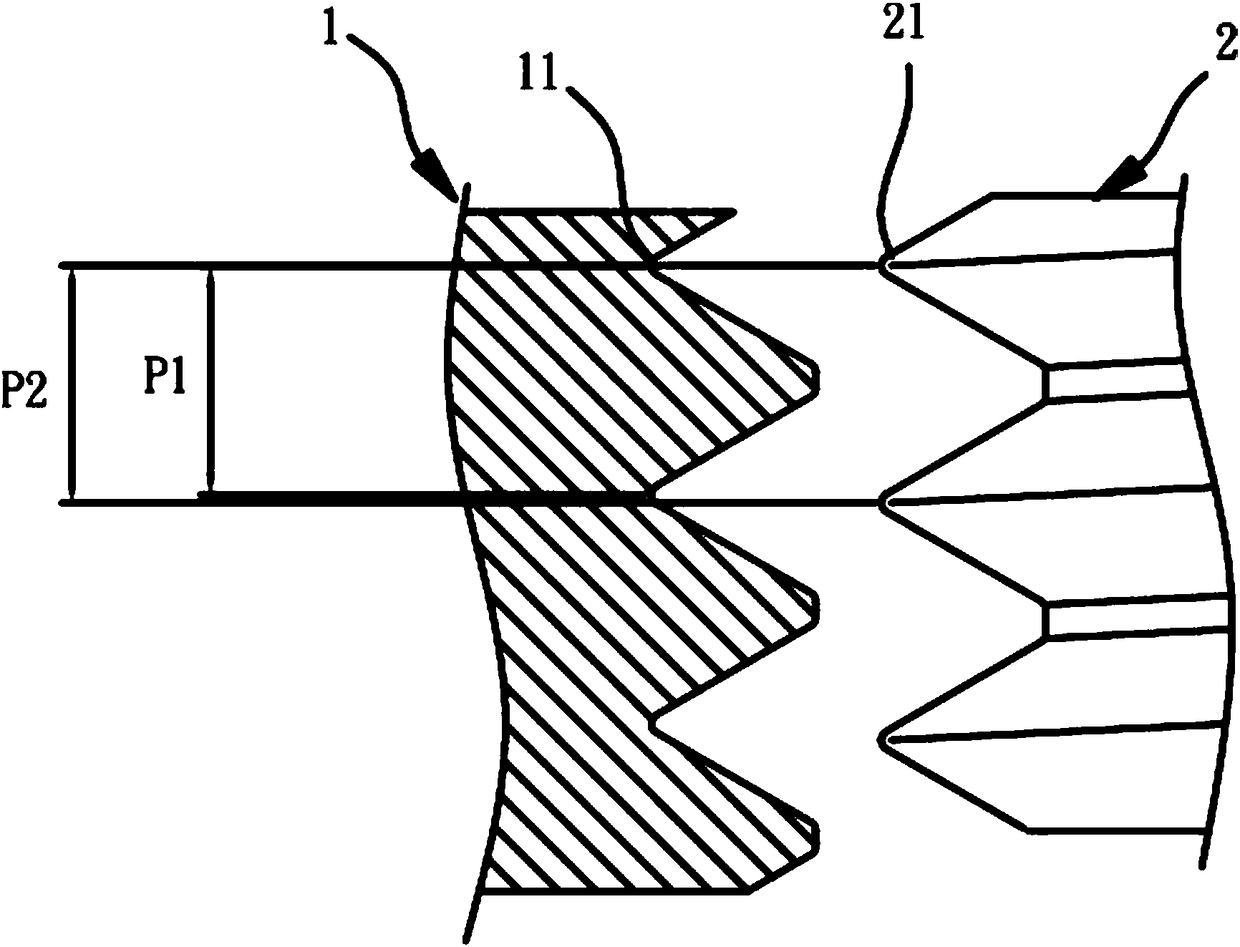

[0045] For example, please refer to Figure 4 , 5 , The minor diameter of the internal threads 11 of the internally threaded part 1 (the width of the peak diameter of each internal thread 11) and the minor diameters of the external threads 21 of the externally threaded part 2 (each of the external threads 21 is equal to the diameter and width of the screw valley, and the thread height H1 (the straight line distance between the screw peak and the screw valley in the direction orthogonal to the central axis A1) of the internal thread 11 of the in...

Embodiment 3

[0047] Please refer to Figure 7 , Which is the third embodiment of the threaded screw structure of the present invention. The main difference between the third embodiment of the present invention and the above-mentioned first embodiment is: in addition to the aforementioned pitch difference, the third embodiment of the present invention also makes the internal threaded member 1 The thread angle θ1 of each of the internal threads 11 is the same, the thread angle θ2 of each of the external threads 21 of the externally threaded component 2 is the same, and the thread angle θ1 of each of the internal threads 11 of the internally threaded component 1 is smaller than that of the The thread angle θ2 of each external thread 21 of the external thread member 2. Moreover, in the third embodiment of the present invention, the nut and the screw that can be screwed and locked with each other are still described, but it is not limited thereto.

[0048] Please refer to Figure 7 , 8 According t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com