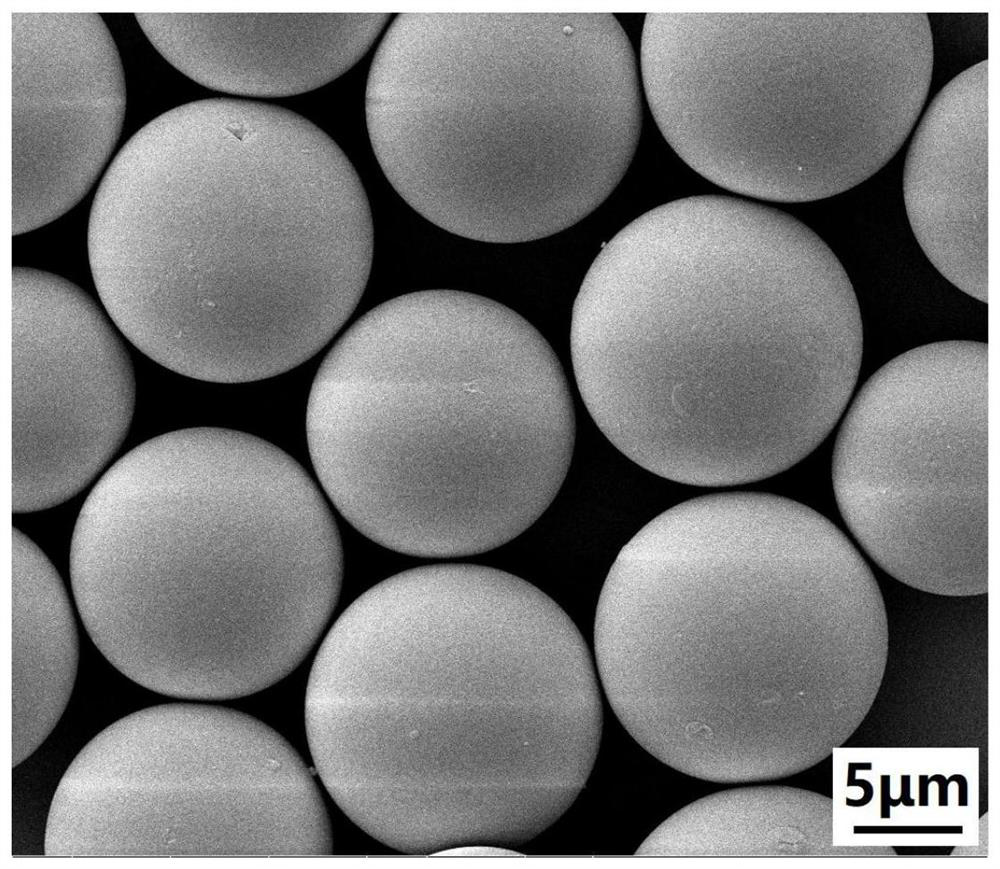

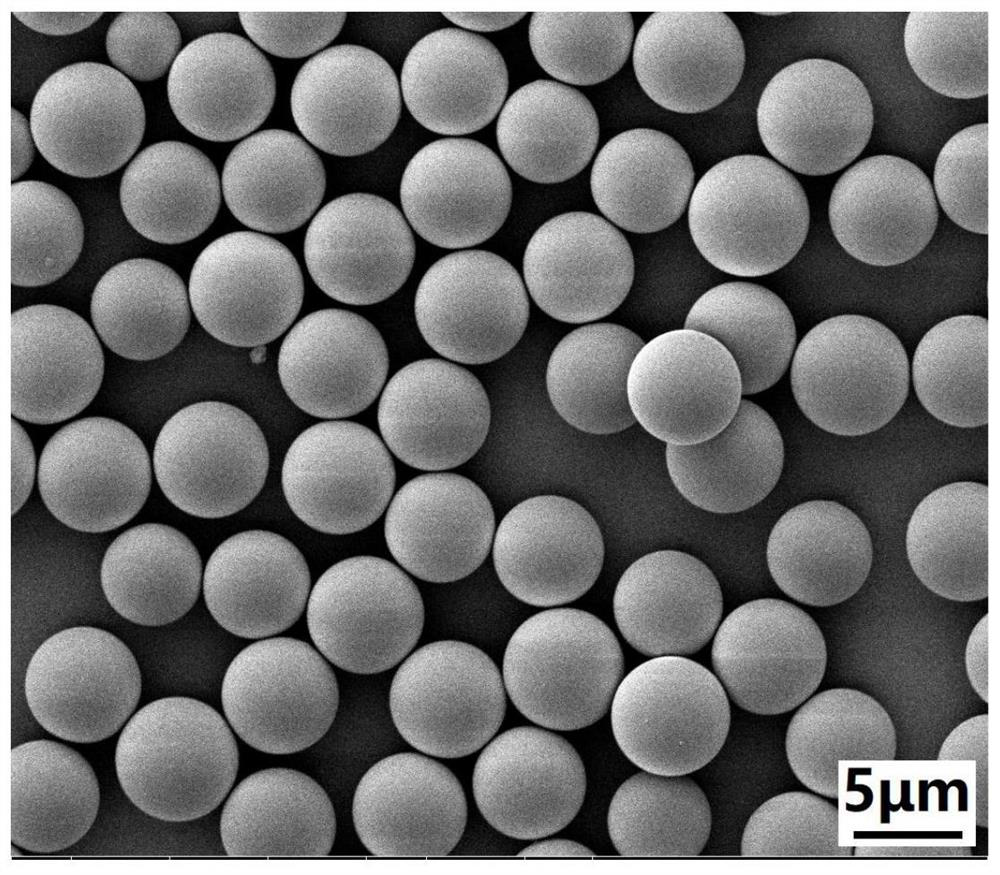

A method for preparing silicon-containing polyurea monodisperse microspheres with high yield by precipitation polymerization

A monodisperse microsphere, high-yield technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of low preparation efficiency and difficulty in realizing industrial-scale production, and achieve the effects of simple steps, efficient preparation, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Technical scheme of the present invention is as follows:

[0011] A method for preparing silicon-containing polyurea monodisperse microspheres with high yield by precipitation polymerization, comprising the steps of:

[0012] At room temperature, diisocyanate and polyamine are subjected to gradual precipitation polymerization in a reaction medium, wherein,

[0013] Silicon-containing polyamines account for 10-100% of the polyamines, and the remainder is ordinary polyamines that do not contain silicon;

[0014] The total amount of diisocyanate and polyamine monomer is 1-32% of the total mass of the system;

[0015] The molar ratio of the amine groups in the polyamine to the isocyanate groups in the diisocyanate (NH 2 / NCO) is 0.3~1.5:1;

[0016] After the diisocyanate and polyamine monomers are dissolved in the reaction medium, the reaction system is sealed, and the polymerization reaction is carried out at 20-80°C and the oscillation frequency is 0-300osc / min; after ...

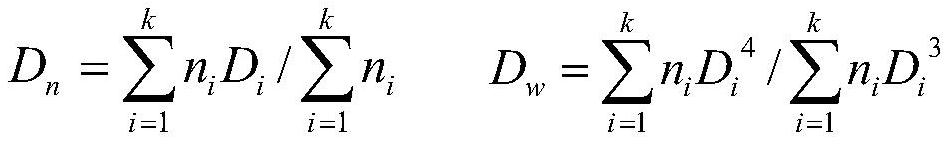

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com