Method for increasing crystallization yield of trichloro sucrose-6-acetate

A sucralose and crystallization technology, applied in the field of increasing the crystallization yield of sucralose-6-ethyl ester, can solve problems such as difficulty in crystallization solvent recovery, poor safety, etc., and achieve reduced product cost, increased crystallization yield, and good purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

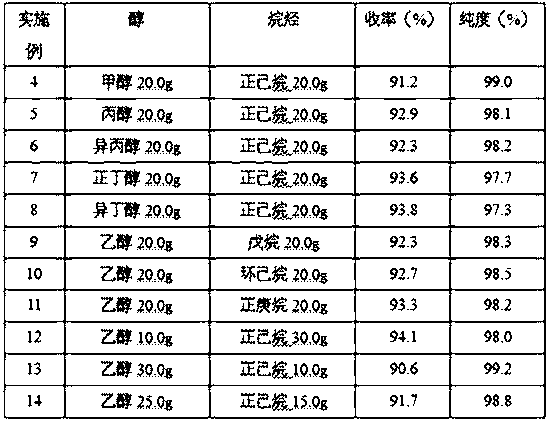

Examples

Embodiment 1

[0011] Embodiment 1: A method for improving the crystallization yield of sucralose-6-ethyl ester mentioned in the present invention comprises the following steps:

[0012] At room temperature, add 30.0 g of crude sucralose-6-ethyl ester (purity 89.0%), 20.0 g of methanol, and 20.0 g of n-hexane into a 100 ml three-necked flask, then raise the temperature to 60°C and stir at this temperature for 1 hour, then Stir at low speed and cool down to room temperature naturally, then cool the above solution to 0°C and let it stand for crystallization for 3 hours, finally filter and dry to obtain 27.6g of sucralose-6-ethyl ester crystals (crystallization yield 92.0%, liquid chromatography detection The purity is 98.5%. The present invention significantly improves the crystallization yield and reduces the product cost under the premise of ensuring the product purity).

Embodiment 2

[0013] Embodiment 2: A method for improving the crystallization yield of sucralose-6-ethyl ester mentioned in the present invention comprises the following steps:

[0014] At room temperature, add 30.0 g of crude sucralose-6-ethyl ester (purity 89.0%), 20.0 g of ethanol, and 20.0 g of n-hexane into a 100 ml three-necked flask, then raise the temperature to 60°C and stir at this temperature for 1 hour, then Stir at low speed and naturally cool down to room temperature, then cool the above solution to 10°C and let it stand for crystallization for 3 hours, finally filter and dry to obtain 26.0 g of sucralose-6-ethyl ester crystals (crystallization yield 86.7%, liquid chromatography detection The purity is 99.3%).

Embodiment 3

[0016] At room temperature, add 30.0g of crude sucralose-6-ethyl ester (purity 89.0%), 20.0g of propanol, and 20.0g of n-hexane into a 100ml three-necked flask, then raise the temperature to 60°C and stir at this temperature for 1 hour. Then stir at low speed and naturally cool down to room temperature, then cool the above solution to -10°C and let it stand for crystallization for 3 hours, finally filter and dry to obtain 28.6g of sucralose-6-ethyl ester crystals (95.3% crystallization yield, liquid phase Chromatographically detected purity was 95.7%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com