Material winding double-taper control method

A control method and double-taper technology, applied in thin material processing, coiling strips, sending objects, etc., can solve the problems of inconsistent deformation of inner and outer coils, wrinkling of the core, and the winding effect cannot meet technical requirements. , to achieve the effect of improving the winding effect, improving the pass rate and neatly winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

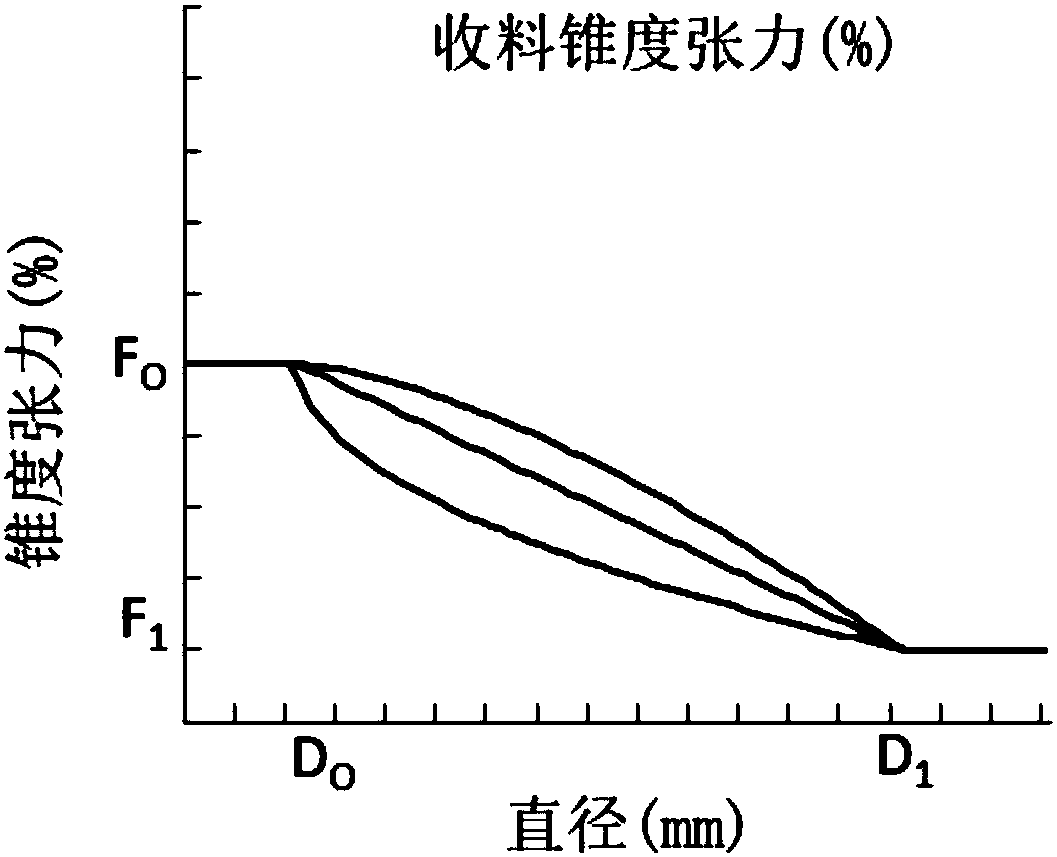

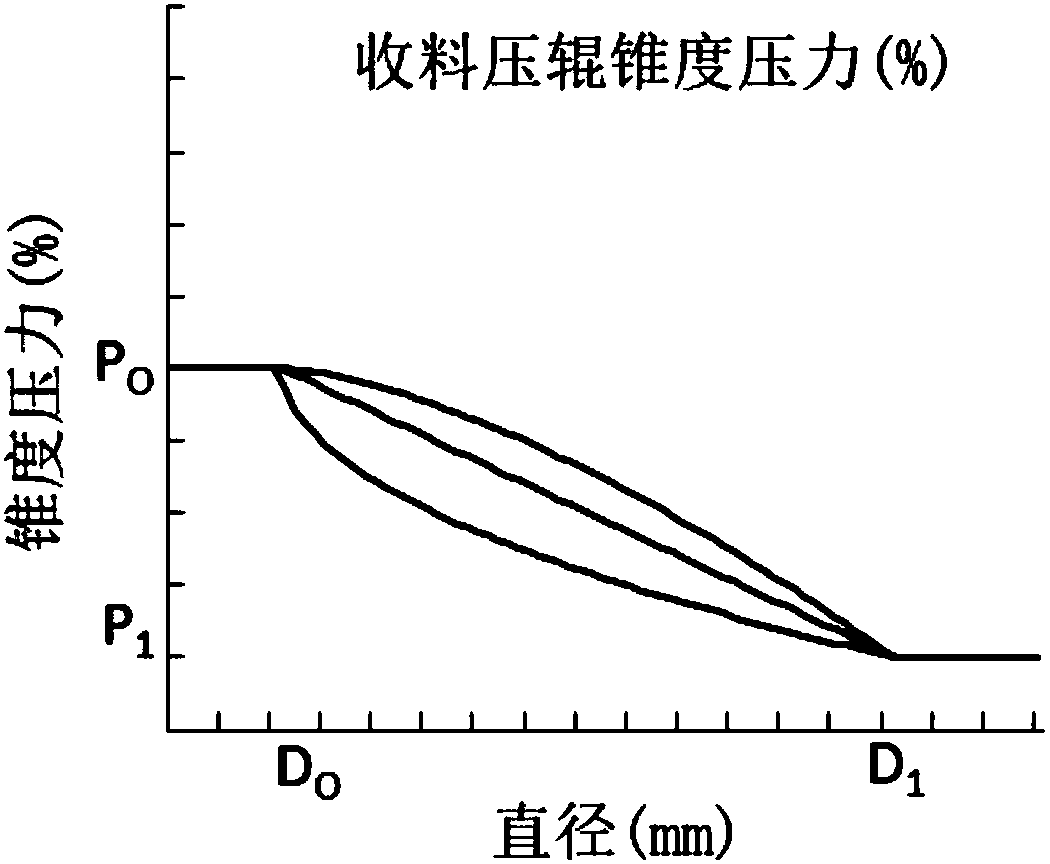

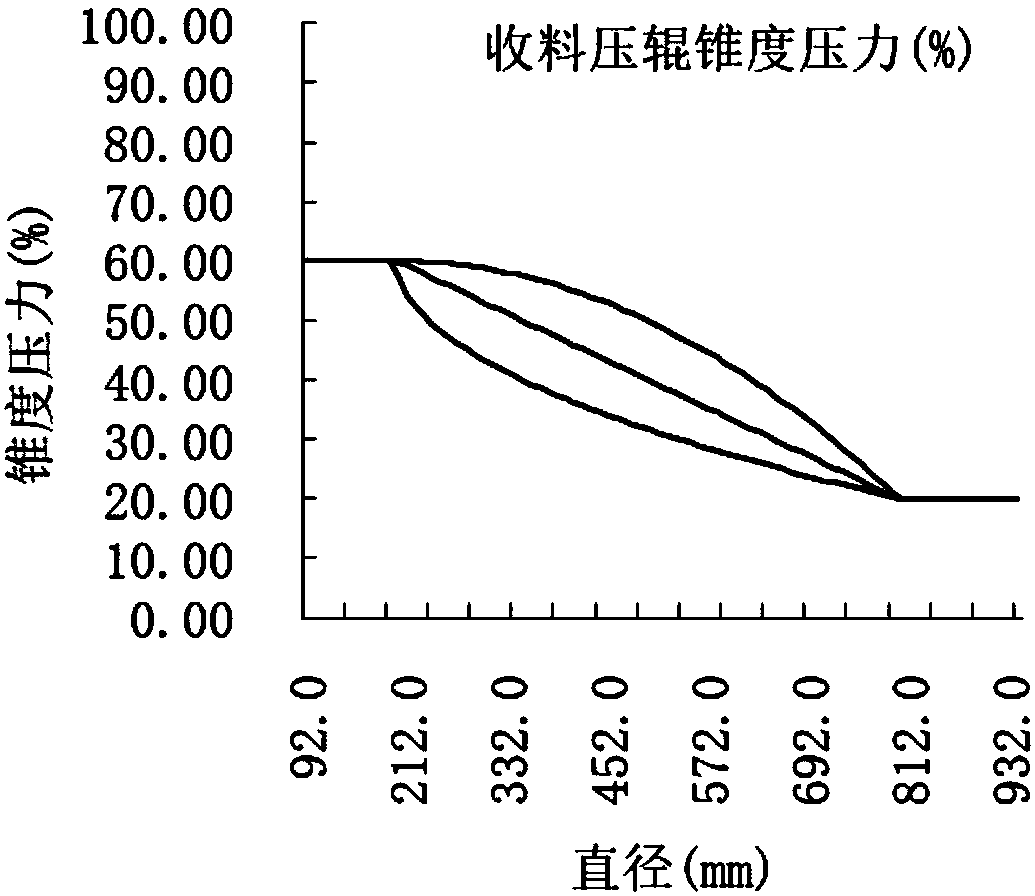

[0040]The following four examples are used to describe the control conditions of different four composite materials. As shown in Table 1, four composite materials are selected, and the initial winding data of the four groups of composite materials are respectively set, and then the winding data of the four composite materials are set. The relational formulas (1), (2) and (3) of the roller pressure and the roll diameter can be obtained from their respective expressions, and the curves of the pressure of the receiving roller and the roll diameter corresponding to each group of materials can be obtained image 3 , Figure 4 , Figure 5 with Image 6 .

[0041] Table 1 sets the initial data for the four materials

[0042]

[0043]

[0044] by the curve image 3 , Figure 4 , Figure 5 with Image 6 It can be seen that the variation law and the function diagram of the four groups of embodiments figure 2 Basically match, therefore the pressure taper control system of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com