Multi-layer co-extruded packaging bag film for drinking water and production method thereof

A multi-layer co-extrusion and production method technology, which is applied in the field of multi-layer co-extrusion packaging bag film for drinking water and its production, can solve the problems of difficult to guarantee hygiene indicators, cross-contamination, incomplete disinfection and sterilization, etc., and achieve the best results Good, fast packing, good tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

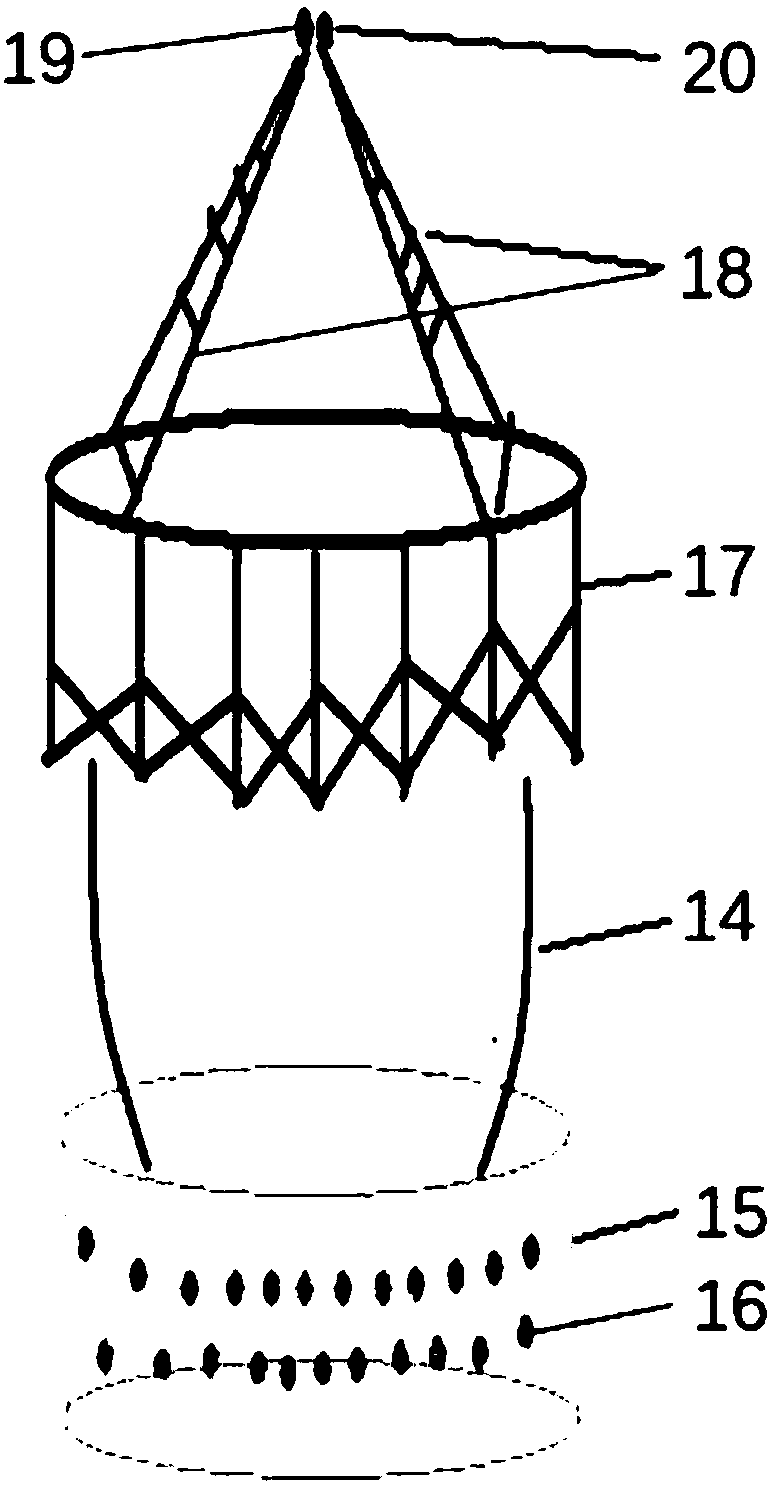

[0039] (1) Preparation and weighing of raw materials: prepare raw material granules according to the components of the nine-layer structure of the multi-layer co-extrusion packaging bag film, and send the raw material granules into the corresponding feeding hopper 10 through a suction device and a weighing device;

[0040] (2) Extruder 11 shear heating: nine extruders 11 respectively shear and heat the raw material particles in the hopper 10 to obtain the raw material in a molten state, and transport it to the die head 13 through the interface;

[0041] (3) Die head 13 extrusion inflation: Extrude and fuse nine layers of molten raw materials at the extrusion port of circular die head 13, and have a film blowing machine inflation device to inflate the film to obtain film bubble 14;

[0042] (4) Air ring 15 cooling: 48 heating points 16 are arranged on the air ring 15, and the film bubble 14 moves upward under the action of traction. 14 The thickness data of one week is transmit...

Embodiment 2

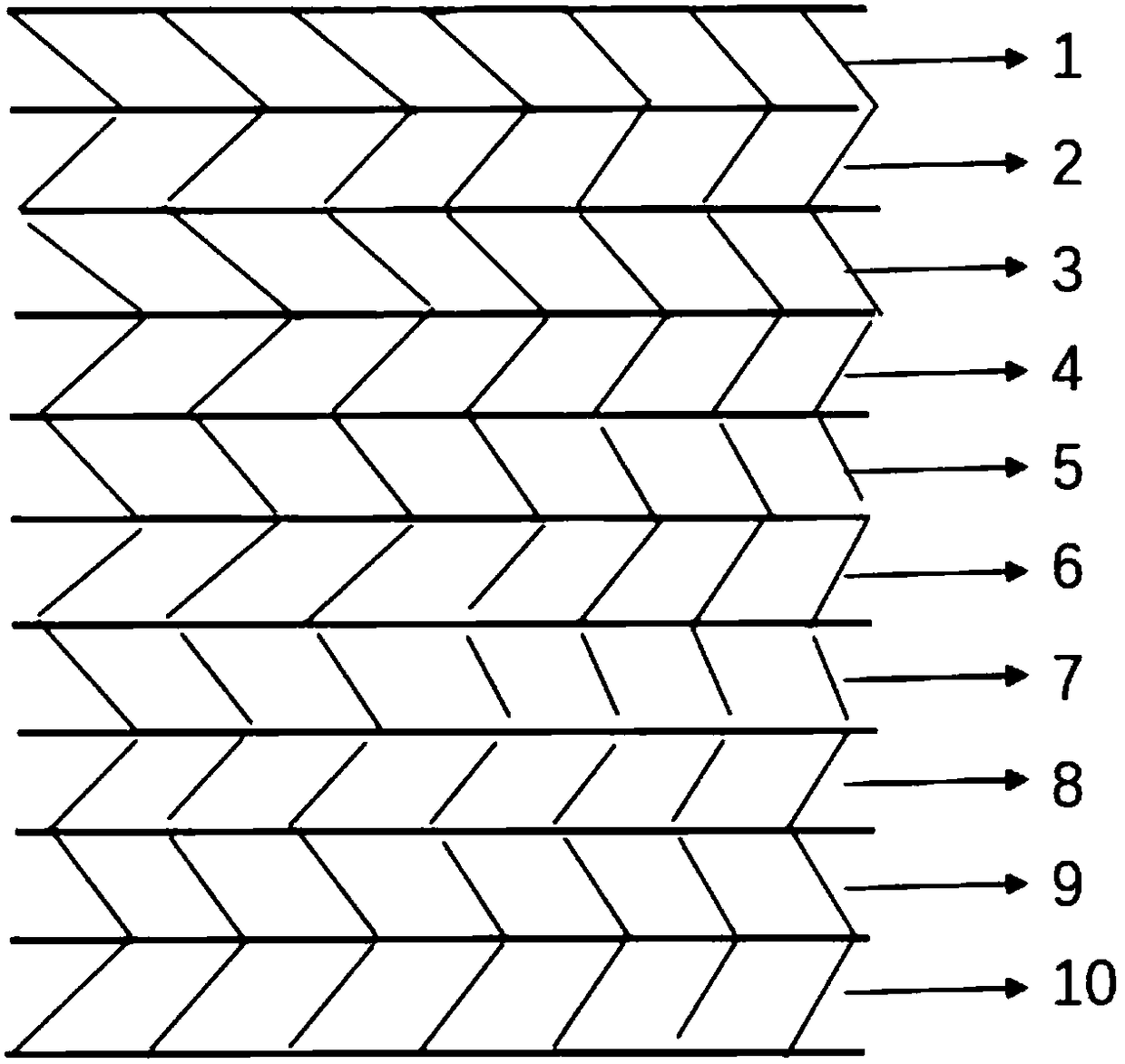

[0062] A kind of multi-layer co-extrusion packaging bag film for drinking water prepared by the preparation method of Example 1, the multi-layer co-extrusion packaging bag film has a total of nine layers of structure, from top to bottom are the first PE layer 1, The second PE layer 2, the third adhesive layer 3, the fourth PA layer 4, the fifth EVOH layer 5, the sixth PA layer 6, the seventh adhesive layer 7, the eighth PE layer 8 and the ninth PE Layer 9.

[0063] The thickness of the first PE layer 1 is 12 μm, the thickness of the second PE layer 2 is 12 μm, the thickness of the third adhesive layer 3 is 6 μm, the thickness of the fourth PA layer 4 is 7 μm, and the fifth EVOH layer 5 The thickness of the PA layer 6 is 5 μm, the thickness of the sixth PA layer 6 is 7 μm, the thickness of the seventh adhesive layer 7 is 6 μm, the thickness of the eighth PE layer 8 is 12 μm, and the thickness of the ninth PE layer 9 is 13 μm.

[0064] The first PE layer is a heat-sealing layer...

Embodiment 3

[0067] A kind of multi-layer co-extruded packaging bag film for drinking water prepared by the preparation method of Example 1, the thickness of the first PE layer 1 is 8 μm, the thickness of the second PE layer 2 is 6 μm, and the third bonding The thickness of the agent layer 3 is 6 μm, the thickness of the fourth PA layer 4 is 4 μm, the thickness of the fifth EVOH layer 5 is 4 μm, the thickness of the sixth PA layer 6 is 4 μm, and the thickness of the seventh adhesive layer 7 is 6 μm , The thickness of the eighth PE layer 8 is 6 μm, and the thickness of the ninth PE layer 9 is 8 μm.

[0068] The first PE layer is a heat-sealing layer, the second PE layer is a protective layer, the third layer is an adhesive layer, the eighth PE layer is a protective layer, and the second PE layer is a protective layer. Nine PE layers are heat-sealing layers.

[0069] 3.5% of the mass of the second PE layer is added to the second PE layer, and the high-efficiency anti-ultraviolet material UV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com