Manipulator system and hardware cap production line provided with same

A technology of manipulators and production lines, applied in the directions of manipulators, program-controlled manipulators, chucks, etc., to achieve the effect of convenient grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

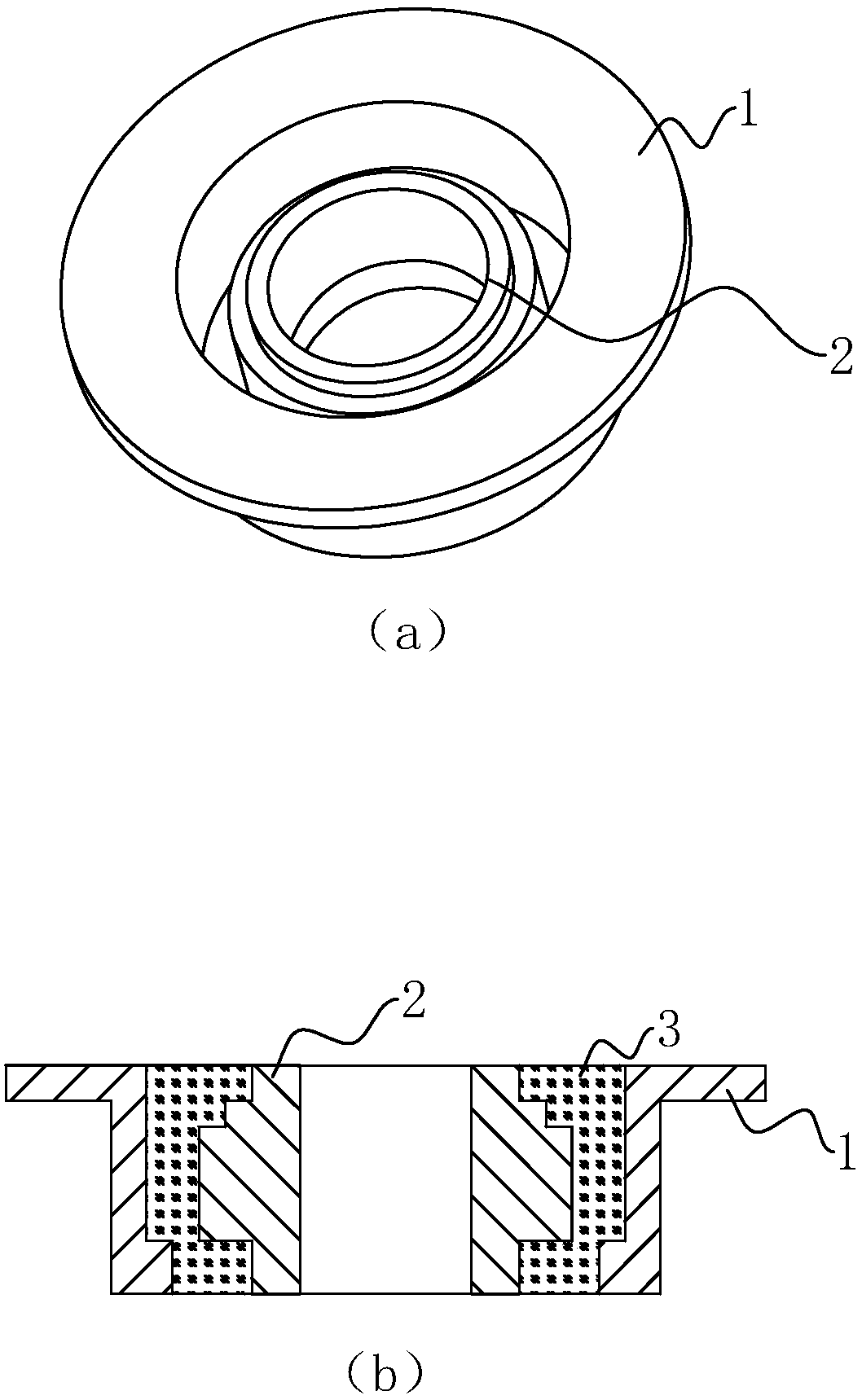

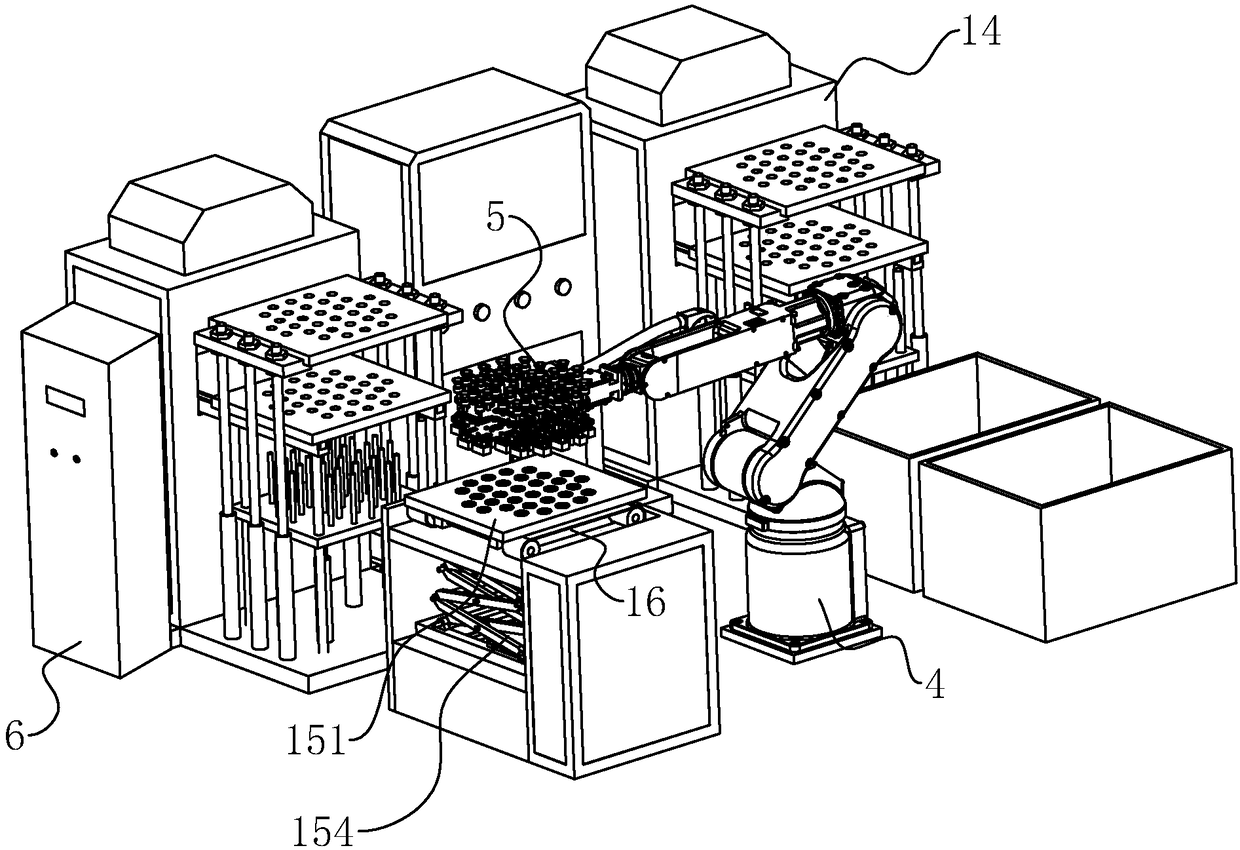

[0046] refer to image 3 and Figure 4 As shown, a manipulator system includes a manipulator 4, a mount 5, and a control box 6 for controlling the movement of the manipulator 4. The control box 6 includes a PLC controller, so that the easy-to-program PLC controller can control the manipulation of the manipulator 4. Mounting seat 5 travels back and forth between the hot press beer machine 14 and the parts transfer box. A magnetic suction device 8 is arranged on one side of the mounting base 5, and a vacuum suction device 7 is arranged on the other side of the mounting base 5. The vacuum suction device 7 corresponds to the magnetic suction device 8 one by one, and the magnetic suction device 8 is used for transferring the bowl. Shaped cap 1, vacuum suction device 7 is used for transferring rubber block.

[0047] refer to Figure 4 and Figure 5As shown, the magnetic attraction device 8 is composed of an electromagnet, and the PLC controller can control the on-off of the circ...

Embodiment 2

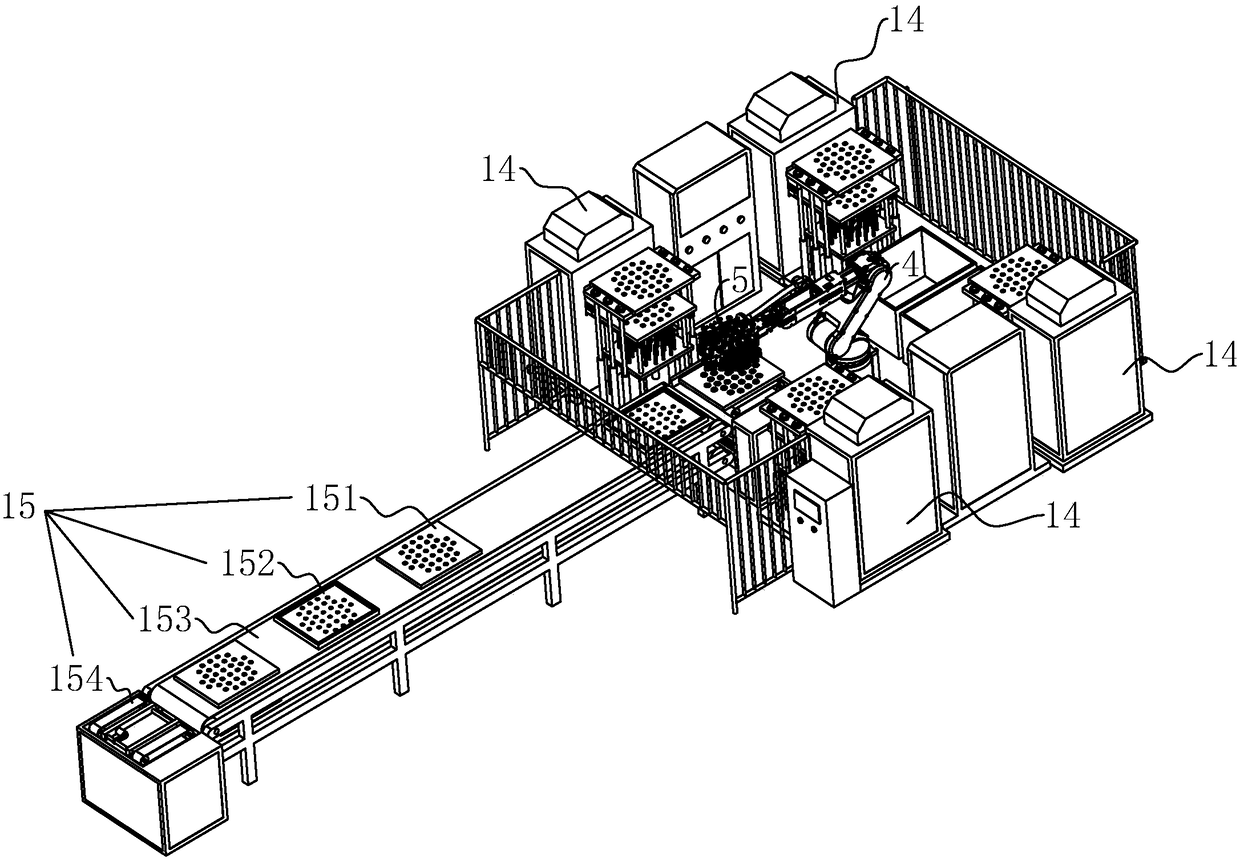

[0051] A production line for hardware caps, including the manipulator system in Embodiment 1, four hot-pressed beer machines 14 located within the graspable range of the manipulator are arranged at intervals in the circumferential direction of the manipulator, and on the side of the manipulator is also provided with a bowl-shaped Conveyor system 15 for caps 1 and rubber blocks.

[0052] refer to figure 2 and Figure 4 As shown, the conveying system 15 includes a first pallet 151 for placing bowl-shaped caps 1 in batches, a second pallet 152 for placing rubber blocks in batches, and an upper and lower pallet for transporting the first pallet 151 and the second pallet 152. The double-layer conveyor belt 153 arranged in layers, the hydraulic lifter 154 arranged at both ends of the conveyor belt, the first tray 151 and the second tray 152 are arranged with accommodating chambers corresponding to the magnetic suction device 8 one by one, so that the magnetic suction device 8 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com