A method for solving the thickness distribution of abrasive grains and its application in grinding process design

A technology of grinding dosage and abrasive grains, applied in the field of grinding, can solve problems such as difficulty in optimization and difficulty in achieving results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

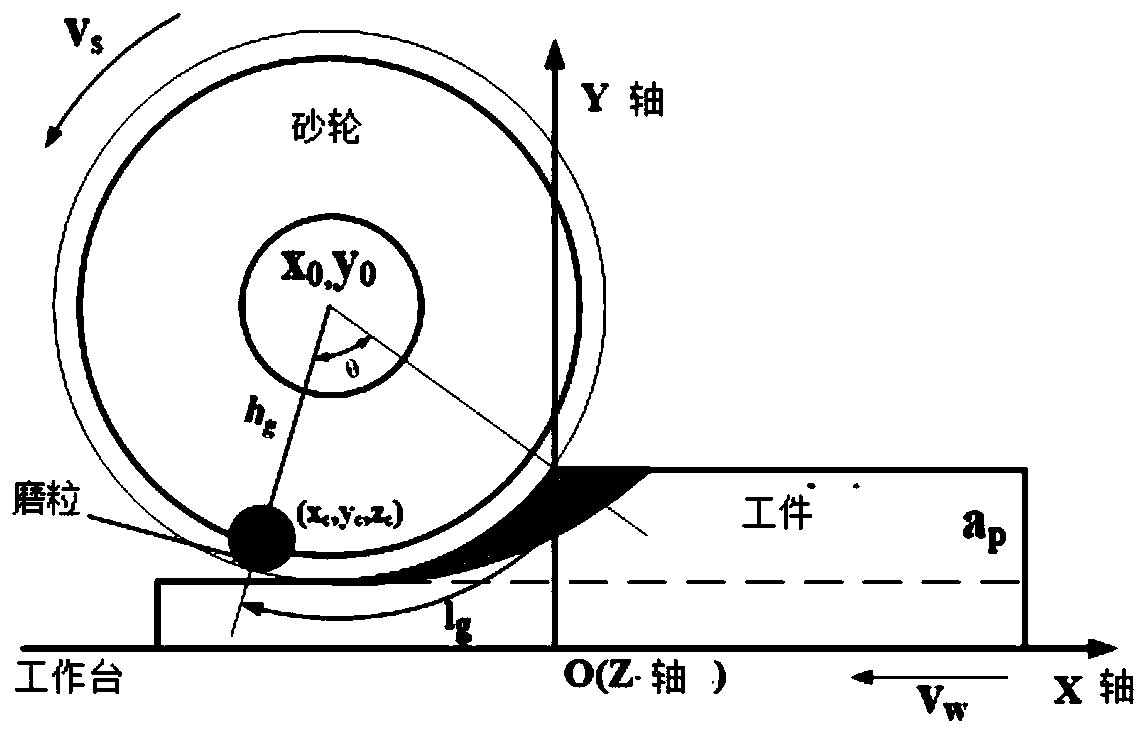

[0052] The method for solving the thickness distribution of abrasive grains is described in detail below in conjunction with the accompanying drawings:

[0053] Grinding wheel parameters are adopted: grinding wheel diameter ds=300cm, width 10cm, abrasive particle parameters are expressed by distribution function, particle size, position and edge height are all normal distribution, distribution parameters are: particle size N(550,0.25), position N(0.1 ,0.4) and edge height N(67,0.15), the grinding amount is: grinding speed vs=78m / s, feed speed vw=15m / min, grinding depth is 8um.

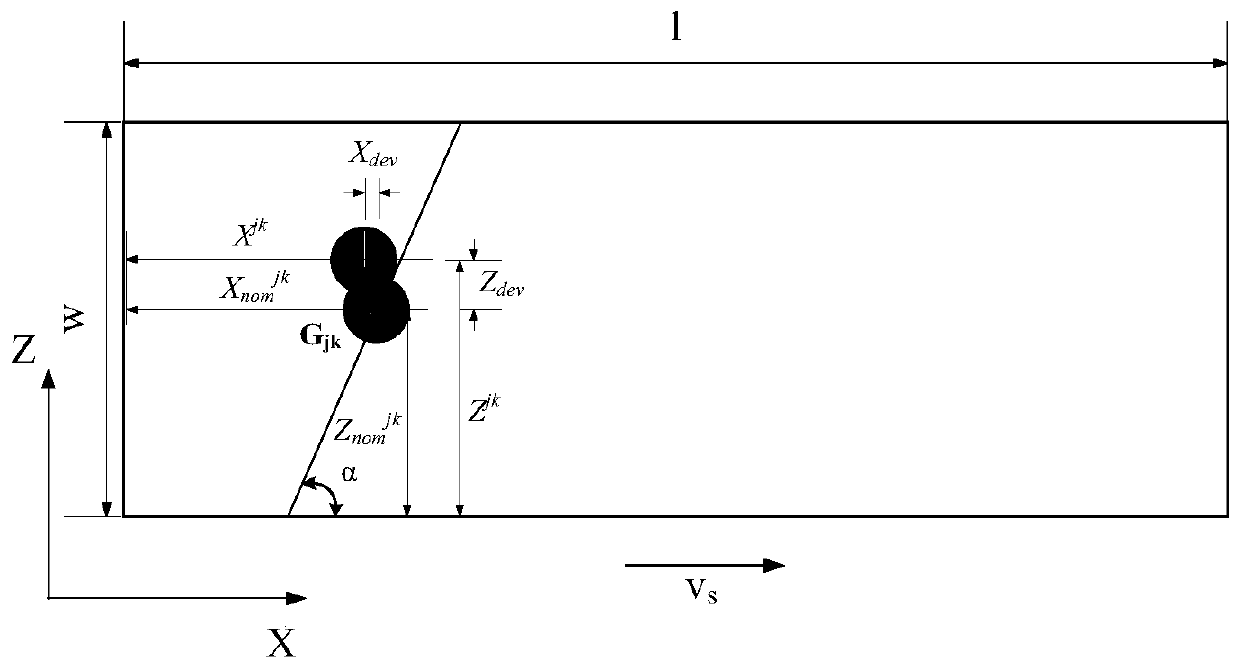

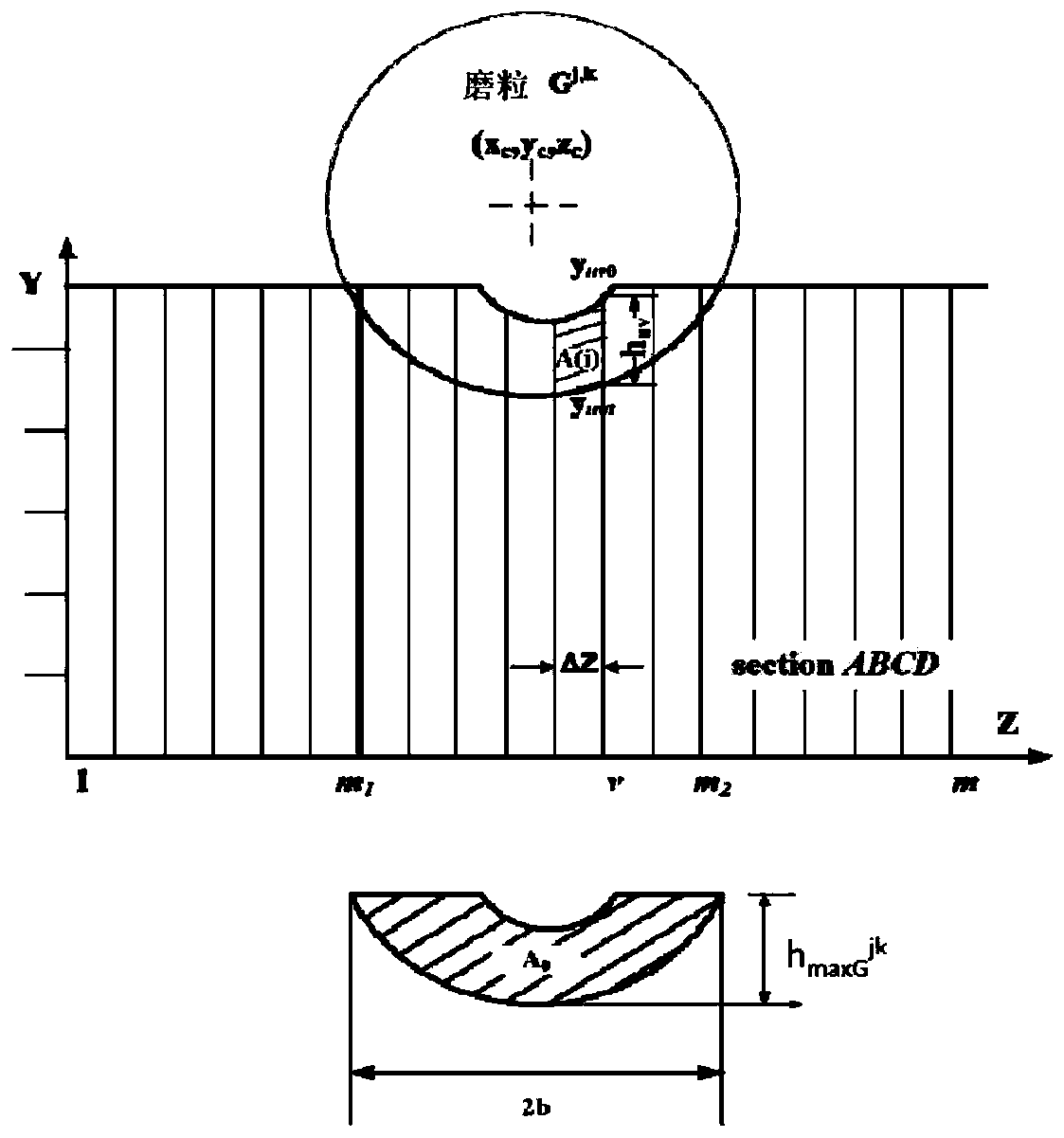

[0054] Step A. Construct a digital grinding wheel: express the abrasive grain parameters on the surface of the grinding wheel as a matrix {G jk} p×q , p×q means that the matrix {Φ} is a matrix with p rows and q columns, that is, the outer circle of the grinding wheel has p rows and q columns of abrasive particle distribution, in this embodiment p=9000, q=20; element G jk Indicates the abrasive grains...

Embodiment 2

[0072] This embodiment explains in detail the specific implementation method of the application method of a method for solving the thickness distribution of abrasive grains in the design of the grinding process:

[0073] In this embodiment, the grinding tool is a grinding wheel, and the grinding process is designed with the goal of obtaining a good machined surface quality. The workpiece is No. 45 steel, and the surface roughness Ra of the processing result is expected to be less than 0.4um. The user has given a grinding wheel with a diameter of 400mm and a width of 15m. The estimated grinding consumption is: grinding speed vs=100m / s, feed speed vw=10m / min, grinding depth is 5um. The set standard value is that the error of the cut thickness distribution of the two abrasive grains is less than 10%.

[0074] Step 1: Set the target abrasive grain cutting thickness distribution according to the processing results, such as Figure 5 Shown in distribution A.

[0075] Step 2: Acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com