Palm oil midfraction and fat composition containing palm oil midfraction

A technology of oil composition and palm oil, which is applied in the fields of fat production, fat oil/fat separation, food science, etc., can solve the problems of long crystallization process time, poor taste, and great influence of crystallization process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] Preparation method of melting point product in palm oil fractionation

[0105] The invention provides a method for preparing a melting point product in palm oil fractionation, which is characterized in that it has the following steps: (1) fractionate palm oil as a raw material to obtain a palm stearin mixture; (2) extract the palm stearin mixture obtained in step (1) The stearin mixture is fractionated to obtain the melting point product in the fractionation of palm oil.

[0106] In a preferred embodiment of the present invention, the step (1) includes a (1-1) heating step. Heating to 50-80°C in the (1-1) heating step, preferably heating to 55-70°C in the (1-1) heating step. In a specific embodiment of the present invention, the (1-1) heating step is heated to 60°C.

[0107] In the (1-1) heating step, the constant temperature is performed for 1 to 120 minutes after the heating, and preferably in the (1-1) heating step, the constant temperature is performed for 30 to 9...

Embodiment 1

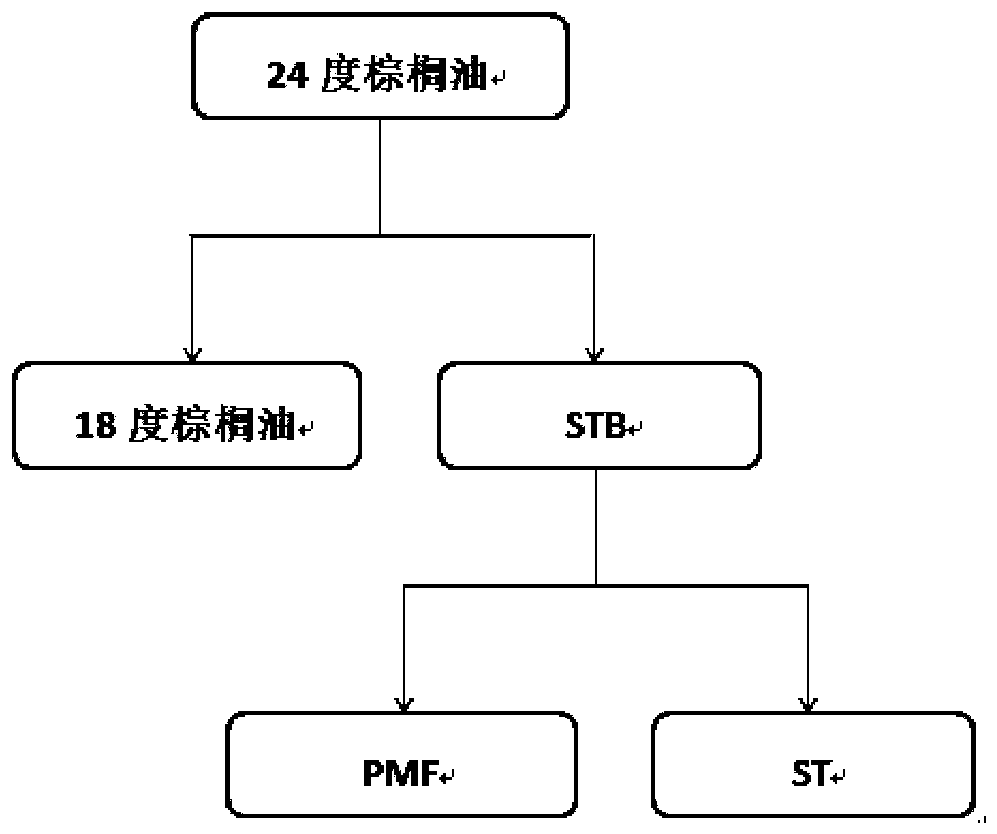

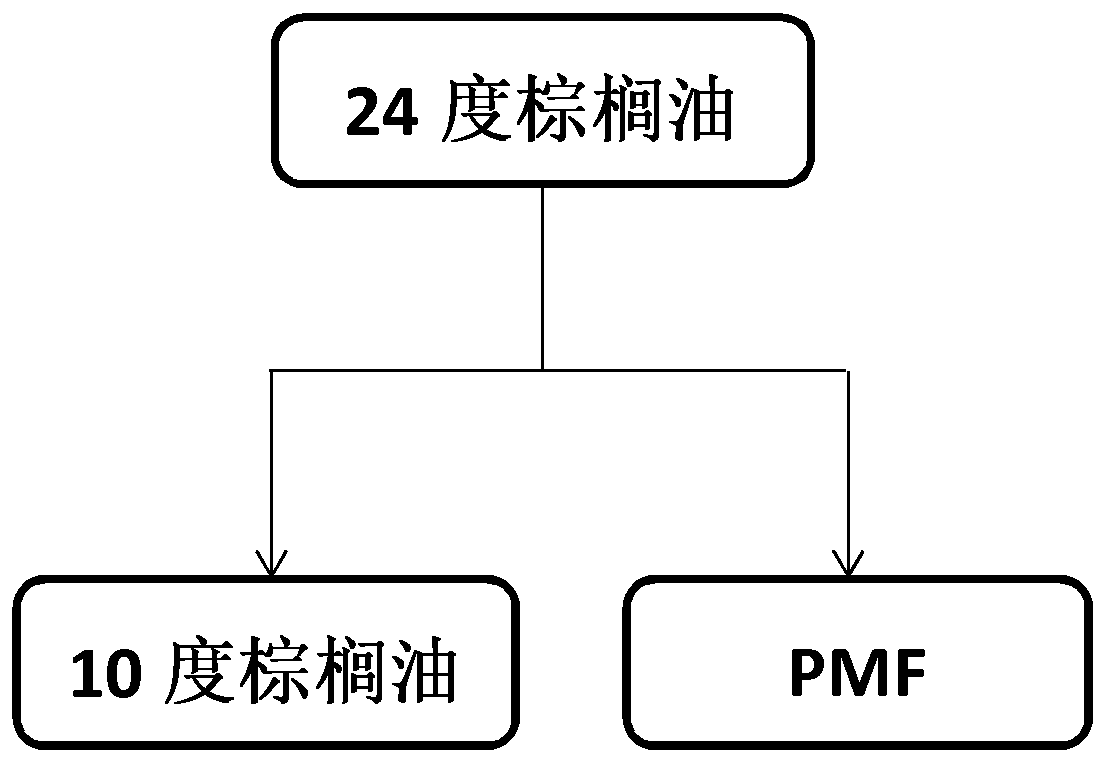

[0178] Using palm oil at 24°C as raw material, PMF with a steeper solid-fat curve and more stable quality was obtained through the following two-step fractionation (crystallization).

[0179]The first step of fractionation: use palm oil (10kg) at 24°C as the raw material to produce STB, and carry out cooling crystallization according to the crystallization steps shown in Table 1.

[0180] The operation steps of the first step of fractionation are shown in Table 1. The specific operation steps are as follows: put 10kg of 24-degree palm oil into the crystallization tank of the dry fractionation test equipment, first heat the water temperature to 60°C, and keep it warm for 60min , Turn on the stirrer and stir at a speed of 40 rpm to completely melt the raw material oil and eliminate crystallization memory. In the second step, the water temperature is uniformly cooled from 60°C to 30°C within 60 minutes, and the stirring speed is 40 rpm. In the third step, the water temperature i...

Embodiment 2

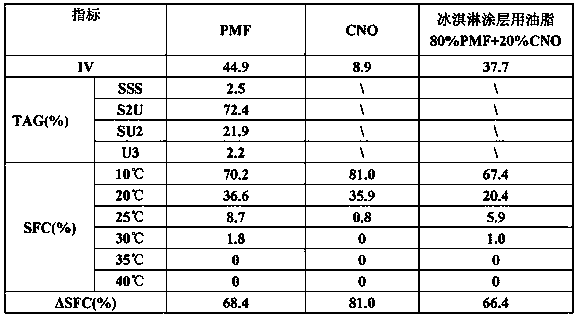

[0188] Using the by-product STB (5kg) of palm oil fractionated at 18°C in the factory as the raw material, carry out cooling crystallization according to the crystallization steps 1 to 3 shown in Table 2, and carry out cooling crystallization with reference to the operation method of Example 1. After the crystallization is completed, the crystallized The slurry was filtered with a filter press pressure of 6kg. The properties of the product obtained by fractionation were shown in Table 5. PMF with an S2U content of 73.7% and a ΔSFC of 69.7% could be obtained, and the fractionation yield reached 92.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com