Quantitative test method for whitening of coating film

A test method, coating technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

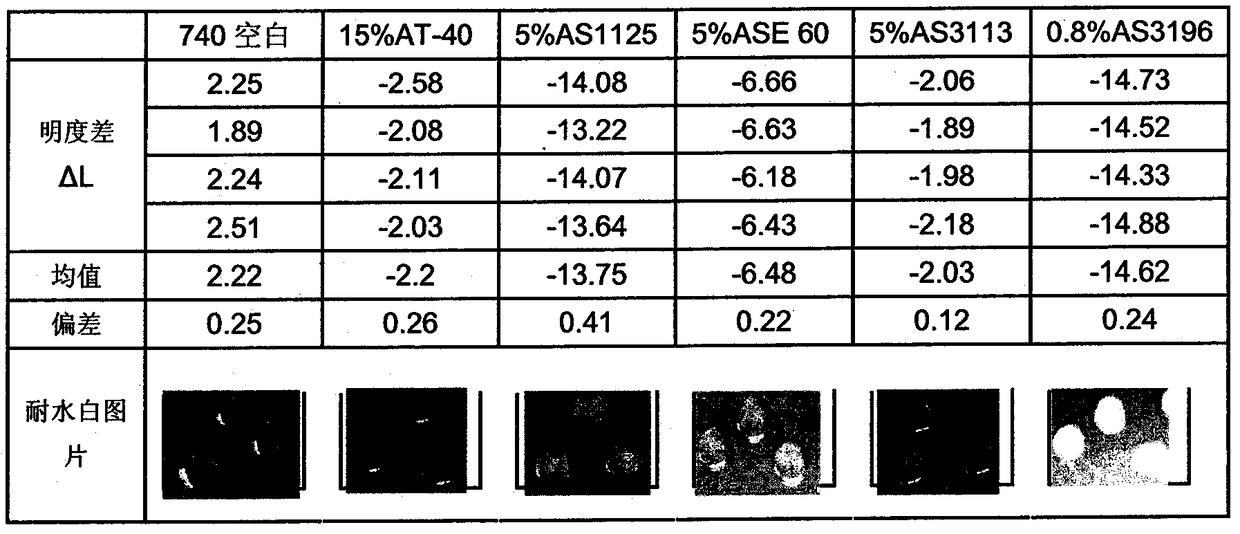

Embodiment 1

[0027] Test item: 8h water whitening resistance

[0028] Testing process:

[0029] Configure the sample paint of the coating film; in this step, the sample paint is container wood floor varnish, and the supplier is Shanghai Qinglan Wood Industry;

[0030] Prepare the prepared coating on a transparent glass plate with a 250 μm wet film maker to prepare a 250 μm wet coating film, and dry it at room temperature for 7 days before use;

[0031] Use a medium solution to test the water whitening resistance in some areas of the dried coating film, and then use a paper towel to dry the liquid on the surface of the coating film; in this step, use a 0-1000 μml microtube to measure 200 μml according to the GB / T9274 C method drop method Drip distilled water onto the coating film, drip 3-5 points, do parallel experiments, then cover the droplets with a petri dish or a transparent plastic cup, wait for 8 hours; dry the surface moisture of the sample with a paper towel;

[0032] Use a color...

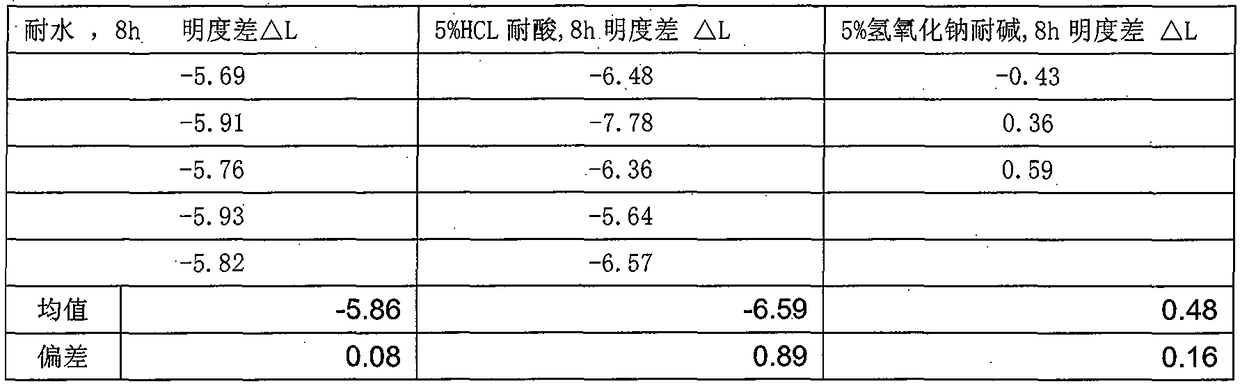

Embodiment 2

[0036] Test item: 8h alkali water whitening resistance

[0037] Testing process:

[0038] Configure the sample paint of the coating film; in this step, the sample paint is container wood floor varnish, and the supplier is Shanghai Qinglan Wood Industry;

[0039] Prepare the prepared coating on a transparent glass plate with a 250 μm wet film maker to prepare a 250 μm wet coating film, and dry it at room temperature for 7 days before use;

[0040] Use a medium solution to test the water whitening resistance in some areas of the dried coating film, and then use a paper towel to dry the liquid on the surface of the coating film; in this step, use a 0-1000 μml microtube to measure 200 μml according to the GB / T9274 C method drop method Drop 5% sodium hydroxide solution on the coating film, drip 3-5 points, do parallel experiments, then cover the droplets with a petri dish or a transparent plastic cup, and wait for 8 hours; dry the liquid on the surface of the sample with a paper t...

Embodiment 3

[0045] Test item: 8h acid water whitening

[0046] Testing process:

[0047] Configure the sample paint of the coating film; in this step, the sample paint is container wood floor varnish, and the supplier is Shanghai Qinglan Wood Industry;

[0048] Prepare the prepared coating on a transparent glass plate with a 250 μm wet film maker to prepare a 250 μm wet coating film, and dry it at room temperature for 7 days before use;

[0049]Use a medium solution to test the water whitening resistance in some areas of the dried coating film, and then use a paper towel to dry the liquid on the surface of the coating film; in this step, use a 0-1000 μml microtube to measure 200 μml according to the GB / T9274 C method drop method Drop 5% hydrochloric acid solution on the coating film, drip 3-5 points, do parallel experiments, then cover the droplets with a petri dish or a transparent plastic cup, wait for 8 hours; dry the liquid on the surface of the sample with a paper towel;

[0050] U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com