Air-sensitive characteristic response curve testing device with outer cover

A technology of response curve and test device, applied in the field of gas-sensing sensors and gas-sensing materials, can solve the problems of poor repeatability of test data, low test accuracy of gas-sensing characteristic response curve, low reliability of test results, etc., so as to improve the test results. Effects of Precision and Confidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

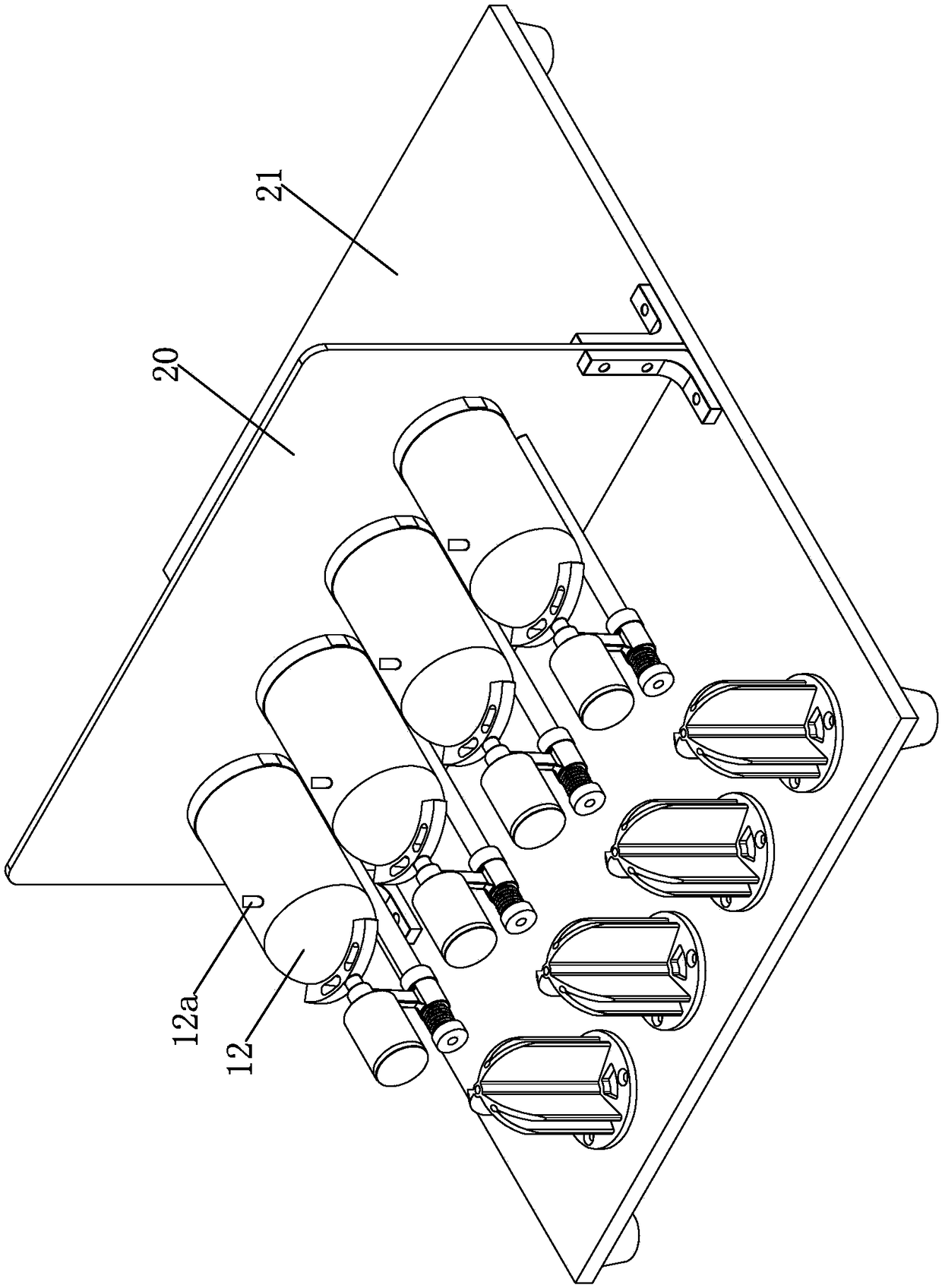

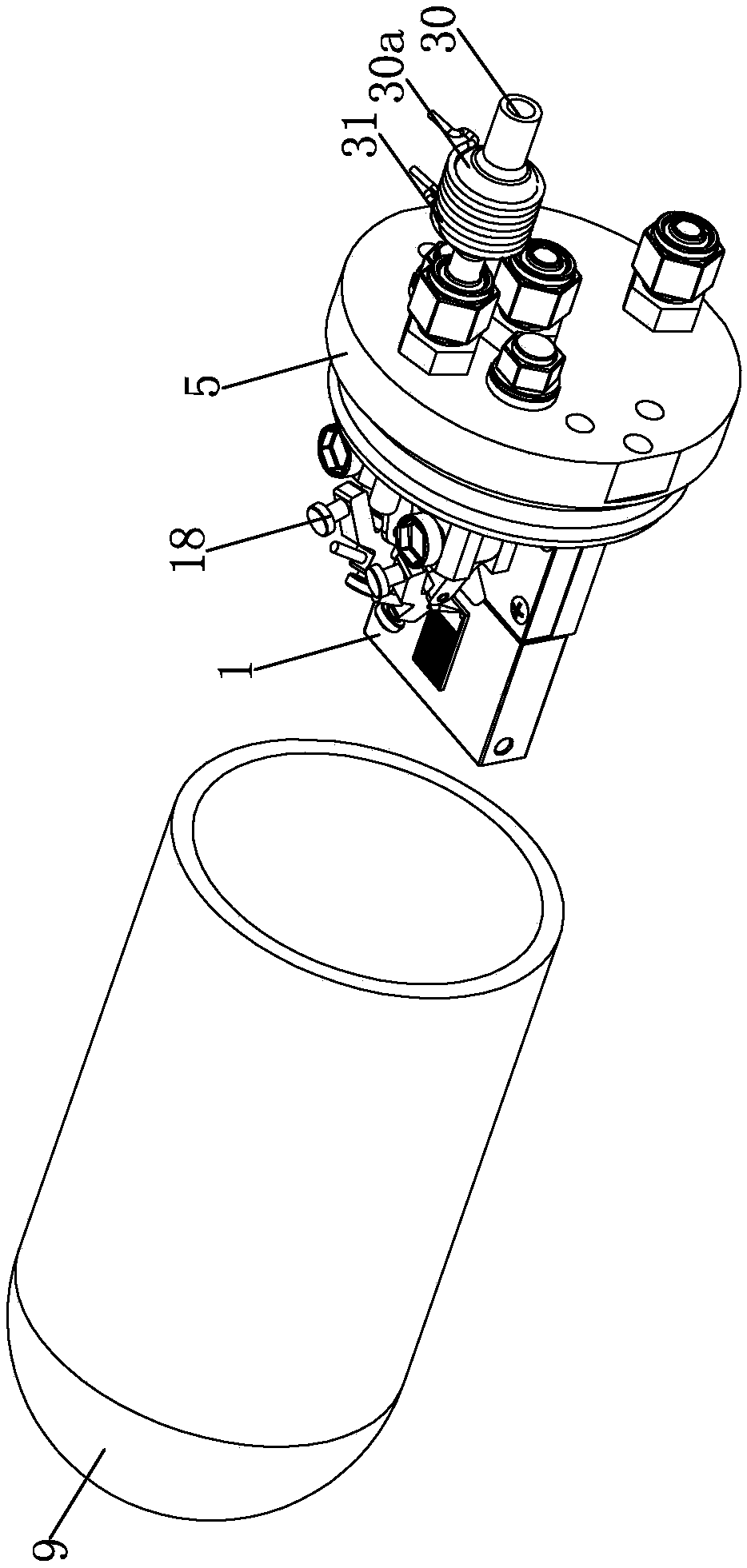

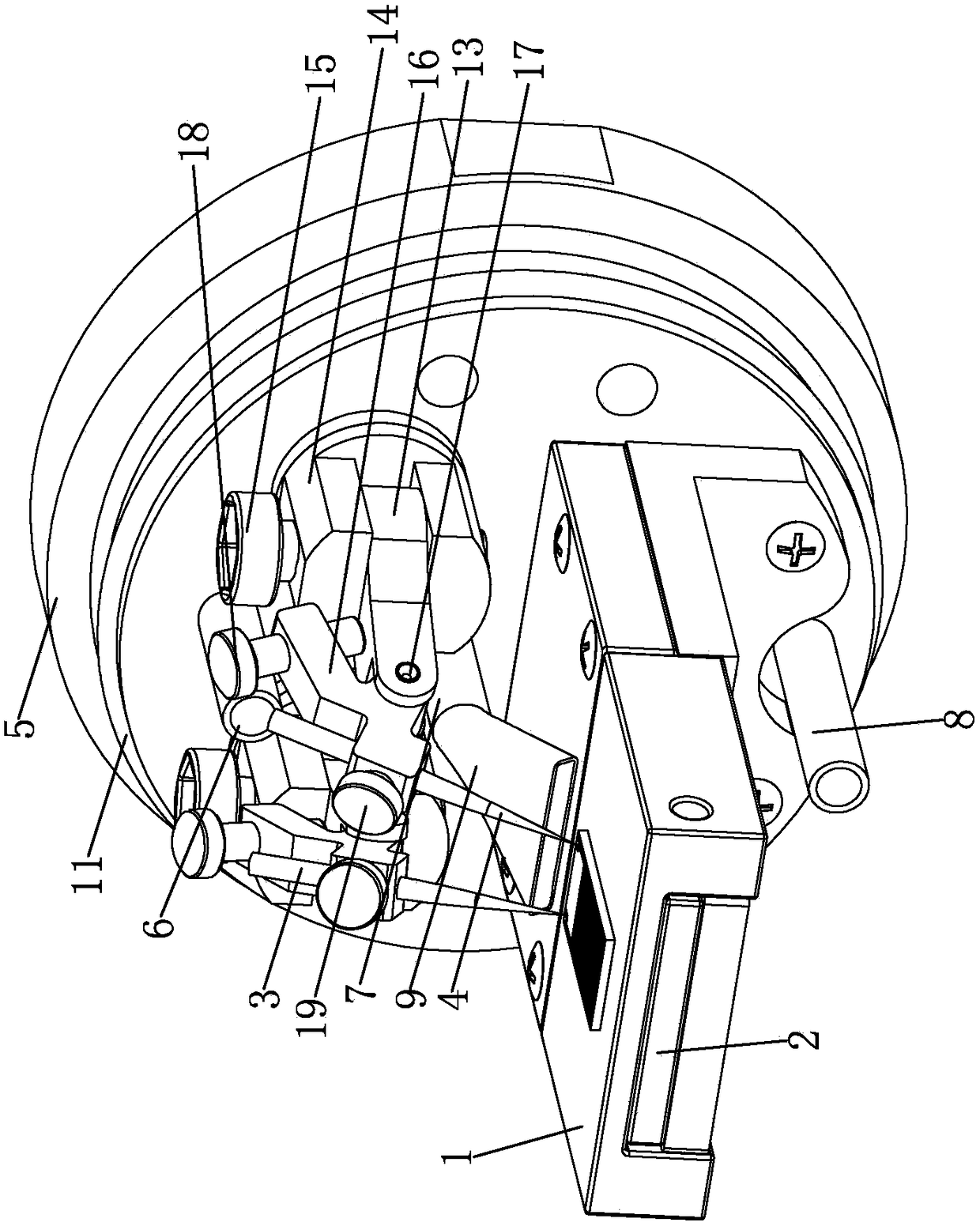

[0022] Such as figure 1 , 2 As shown in and 3, a gas sensitivity characteristic response curve testing device with an outer cover includes a sample carrier 1 and an inner cover 10, wherein the bottom of the sample carrier 1 is provided with a heating plate 2, and the top surface of the sample carrier 1 is used to carry The gas sensitive material to be tested, and the heating chip 2 is a ceramic heating chip. The first probe 3 and the second probe 4 are existing structures. During the test, these two probes are in contact with the surface of the gas-sensitive material to be tested. These two probes are respectively installed on the corresponding mounting components, and the sample load Both the platform 1 and the adjustment assembly are installed on the flange 5 . The first probe 3 and the second probe 4 are respectively connected to the measuring instrumen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com