Stent Graft

A technology of covered stents and bare stents, applied in stents, medical science, blood vessels, etc., can solve problems such as stent rupture and stent isolation function failure, and achieve the effect of inhibiting expansion and reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

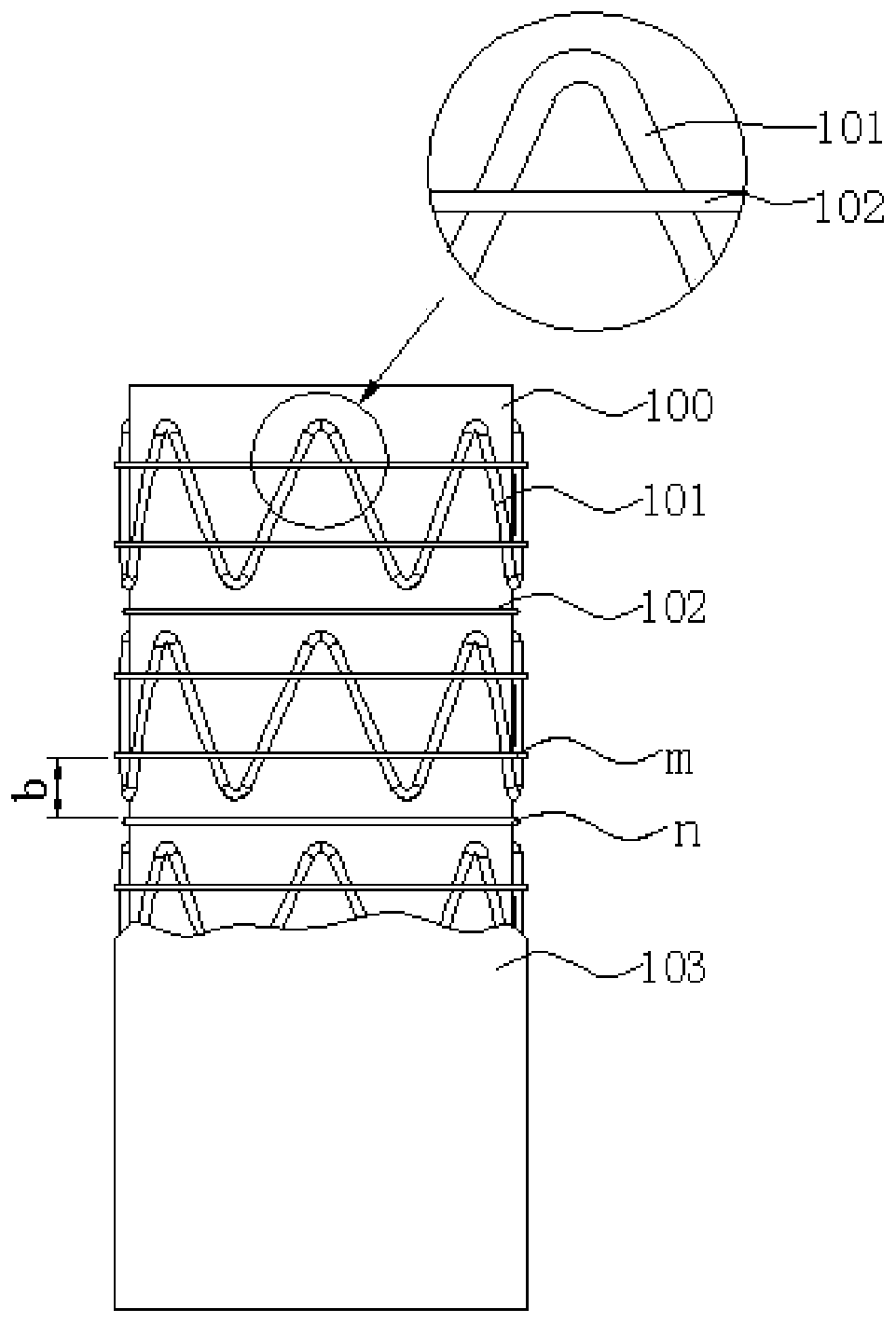

[0049] See figure 2 , a covered stent, comprising an ePTFE inner membrane 100, an ePTFE outer membrane 103, and a self-expandable bare stent 101 disposed between the ePTFE outer membrane 103 and the ePTFE inner membrane 100. The self-expanding bare stent 101 is composed of a plurality of Z-shaped wave coils arranged at intervals along the longitudinal central axis direction of the stent-graft (that is, the axial direction of the stent-graft), and the adjacent upper and lower Z-shaped wave coils do not contact each other; Between the ePTFE outer membrane 103 and the ePTFE inner membrane 100 is arranged a ring-shaped pre-tightened winding PTFE wire 102 . The vertical distance b between two adjacent sections of PTFE wire m and PTFE wire n is in the range of 1-30 mm, preferably 2-12 mm. The PTFE wire 102 is pre-tightened and wound around the outer surface of the self-expandable bare stent 101 in a ring shape (such as figure 2 m) and the outer surface of the ePTFE inner membran...

Embodiment 2

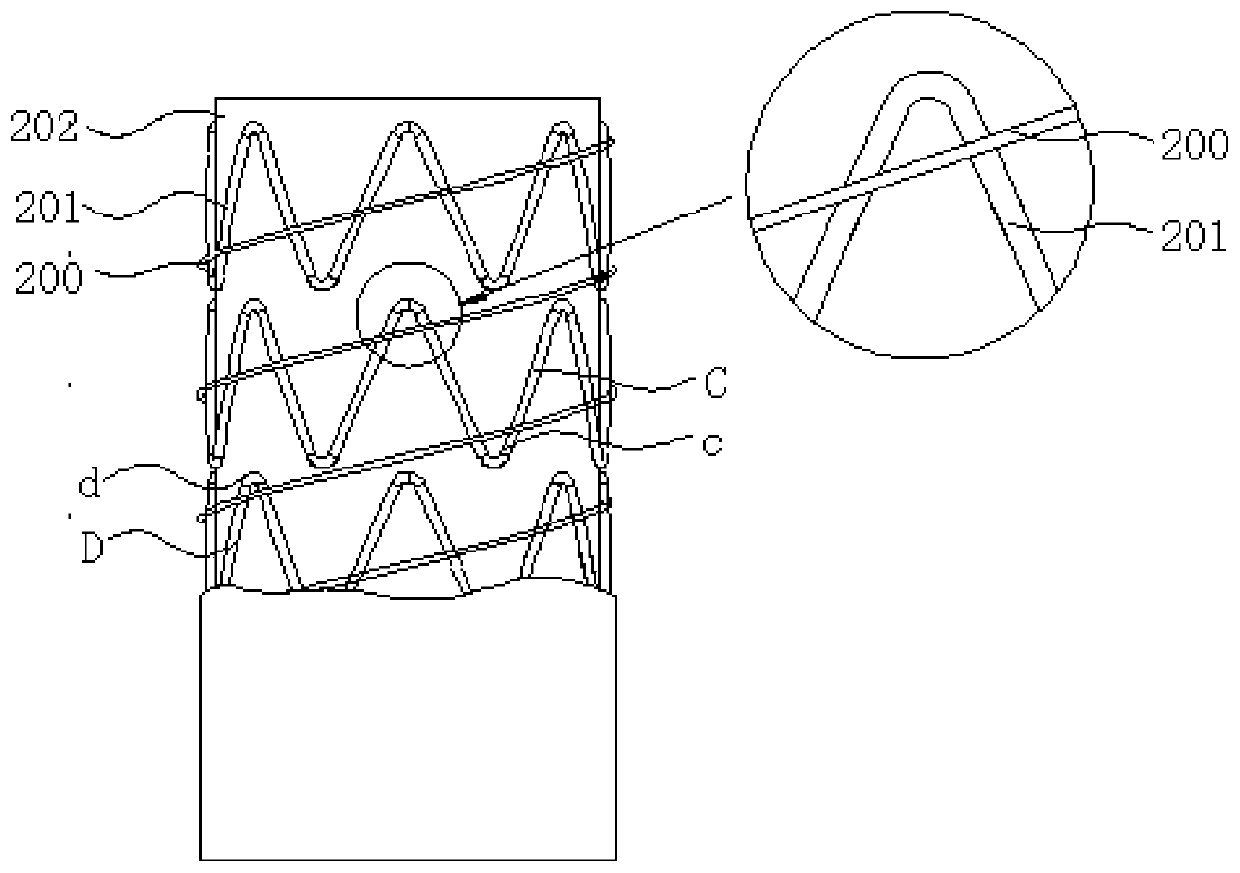

[0056] See image 3 The structure of the stent-graft in this embodiment is similar to that of the stent-graft in Example 1, the only difference is that the PTFE wire 200 is pre-tightened and wound in the outer surface of the self-expandable bare stent 201 and inside the ePTFE in a helical shape. on the outer surface of the membrane 202.

[0057] It should be noted that when the PTFE wire 200 is helically wound on the inner or outer surface of the self-expandable bare stent 201, the PTFE wire 200 can be wound from the corrugated coil C of the self-expandable bare stent 201 to the corrugated coil C. Adjacent wave circle D. For example, see again image 3 , the PTFE wire 200 is wound from the outer surface of the corrugated coil C at the position c of the trough c to the outer surface of the corrugated coil D adjacent to the corrugated coil C at the position d of the crest.

[0058] It can be understood that in other embodiments, the PTFE wire 200 can also be multi-segment or ...

Embodiment 3

[0060] See Figure 4 The structure of the stent-graft in this embodiment is similar to the structure of the stent-graft in Embodiment 1, the only difference is that the PTFE wire 300 in this embodiment is pre-tightened in a ring and wrapped around the inner surface of the self-expanding bare stent 301 and On the outer surface of the inner membrane 302 of ePTFE.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com