On-line liquid nitrogen freezing apparatus capable of realizing continuous production

A liquid nitrogen freezing and equipment technology, applied in the fields of food science, food preservation, application, etc., can solve the problems of low work efficiency and manual removal, and achieve the effect of high work efficiency, small footprint and saving work space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The structural features, working principle and advantages of the online liquid nitrogen freezing equipment of the present invention are described in detail as follows with reference to the accompanying drawings. The following specific embodiments are illustrated by taking food freezing as an example. The working process of using the equipment of the present invention to carry out cryogenic treatment of workpieces is similar to it, so it will not be repeated.

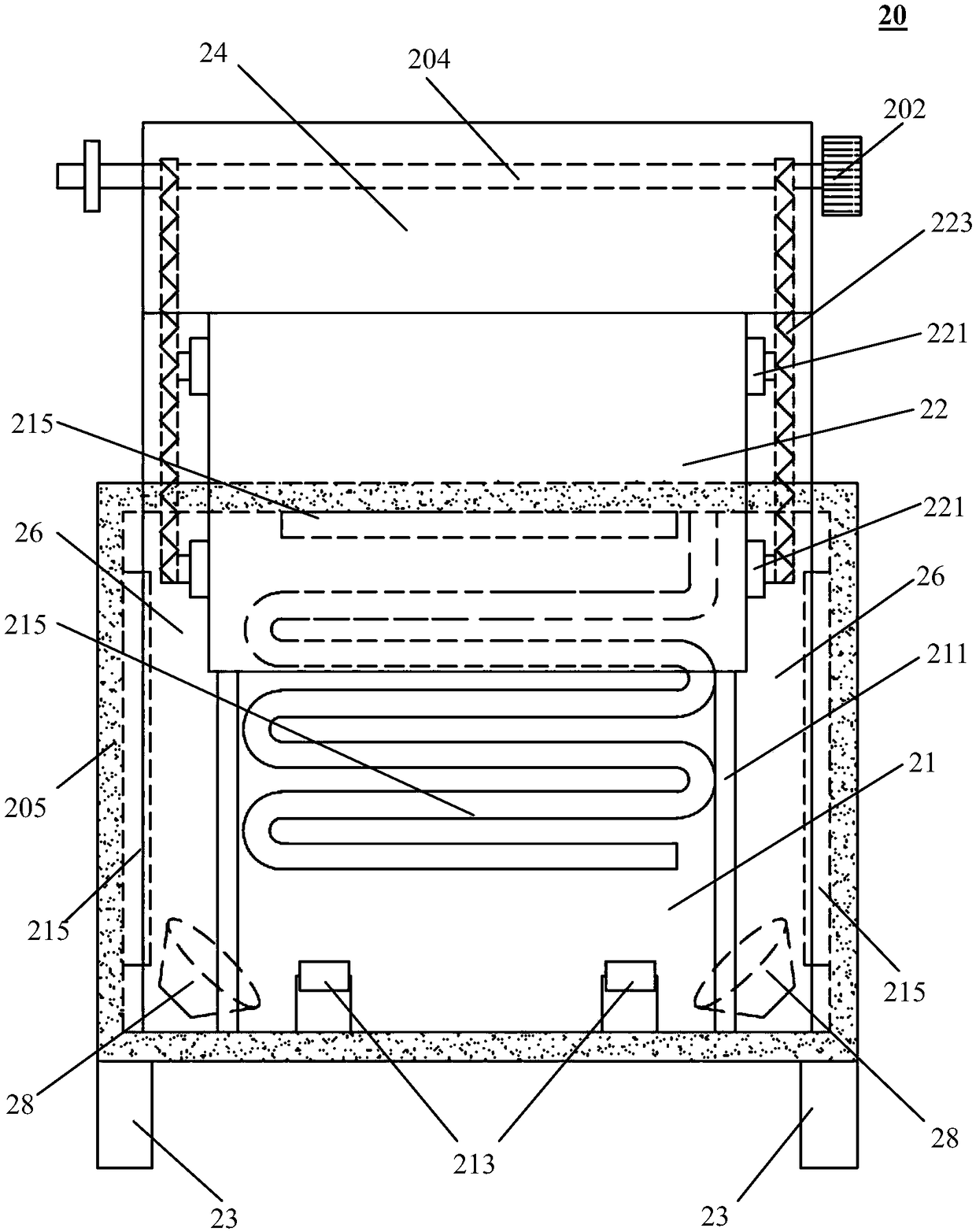

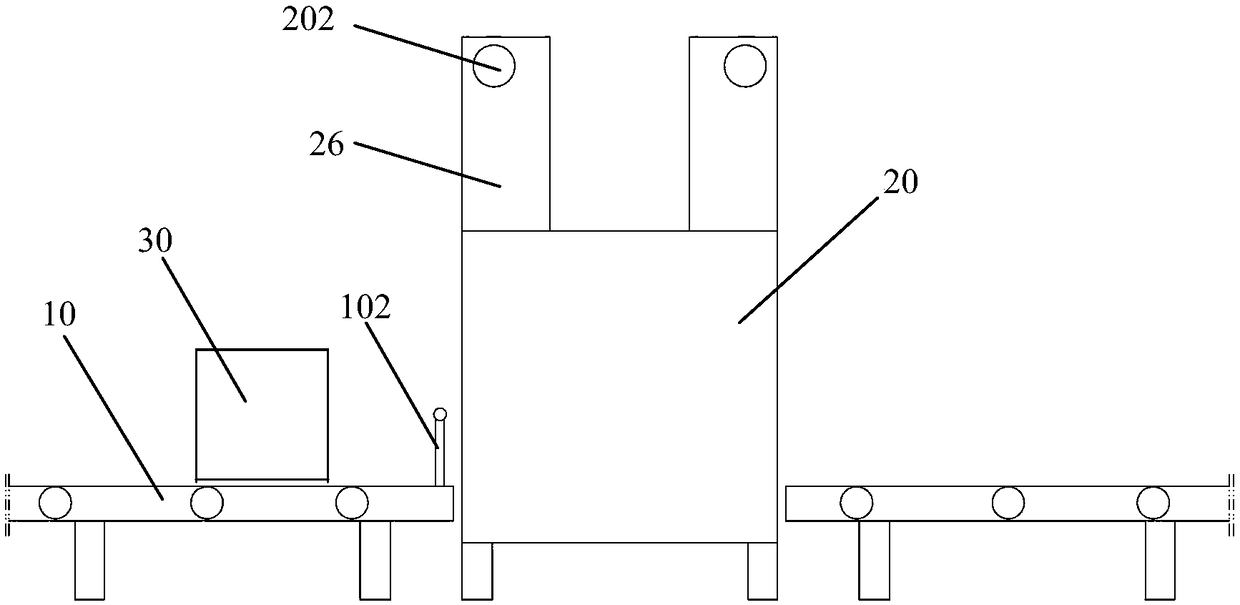

[0016] refer to figure 2 As shown, the online liquid nitrogen freezing equipment 20 capable of continuous production of the present invention is set together with the food processing production line 10, see figure 1 , the online liquid nitrogen freezing equipment 20 includes a cabinet body 21, a movable cabinet door 22 and a door frame 26; the cabinet body 21 and the cabinet door include a shell and an inner wall, and a partition is arranged between the shell and the inner wall Heat layer 205; the cabinet door 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com