Perovskite patterned diaphragm obtained by phase separation means and manufacturing method thereof

A technology of patterned films and fabrication methods, applied in the fields of nanotechnology, electrical components, nanotechnology, etc. for material and surface science, can solve the problem of inability to achieve integrated fabrication of structures and films, and the inability of quantum dots to absorb incident light. It can achieve the effect of excellent scattering performance, improving water and oxygen barrier ability, and weakening the degree of saturation absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

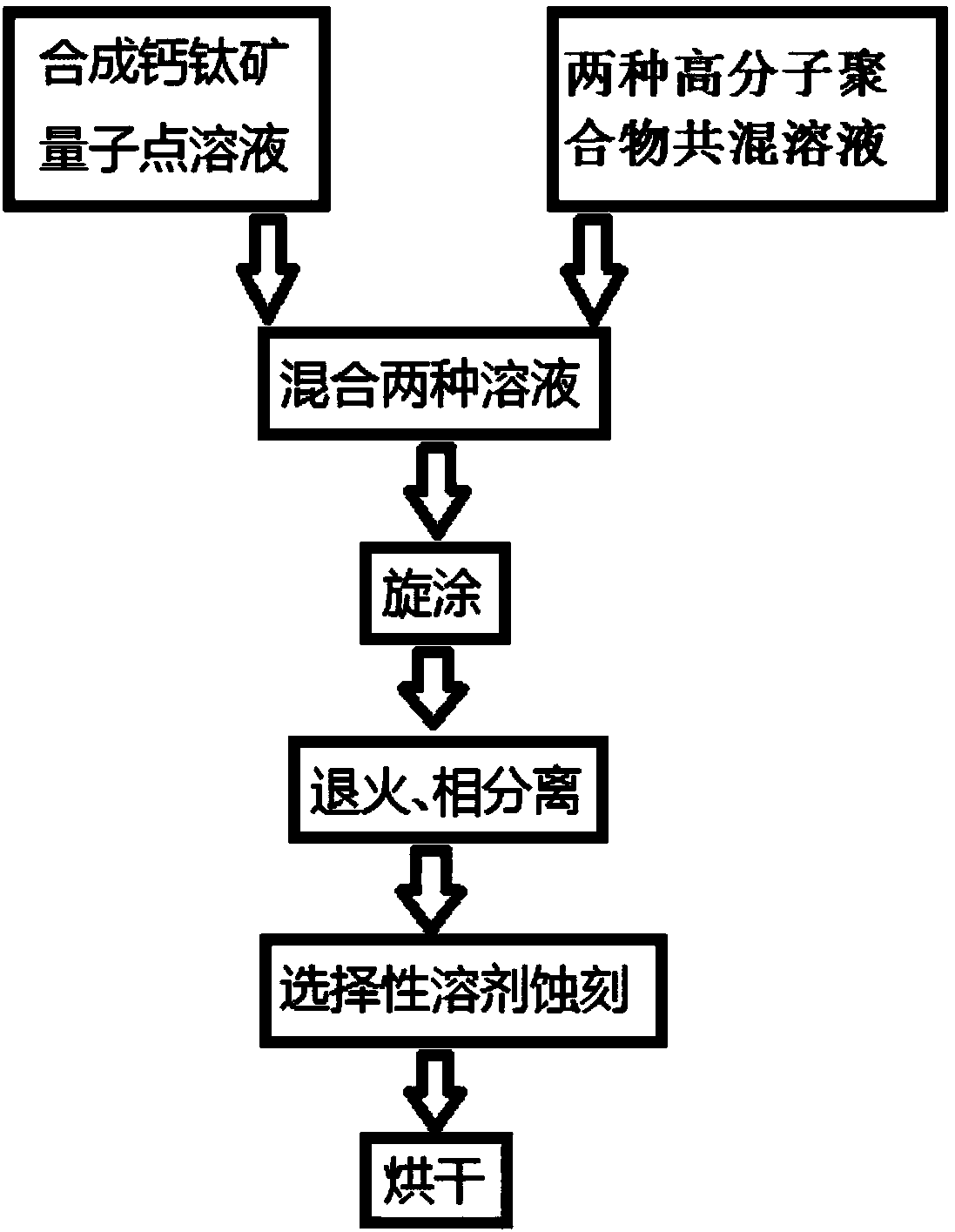

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

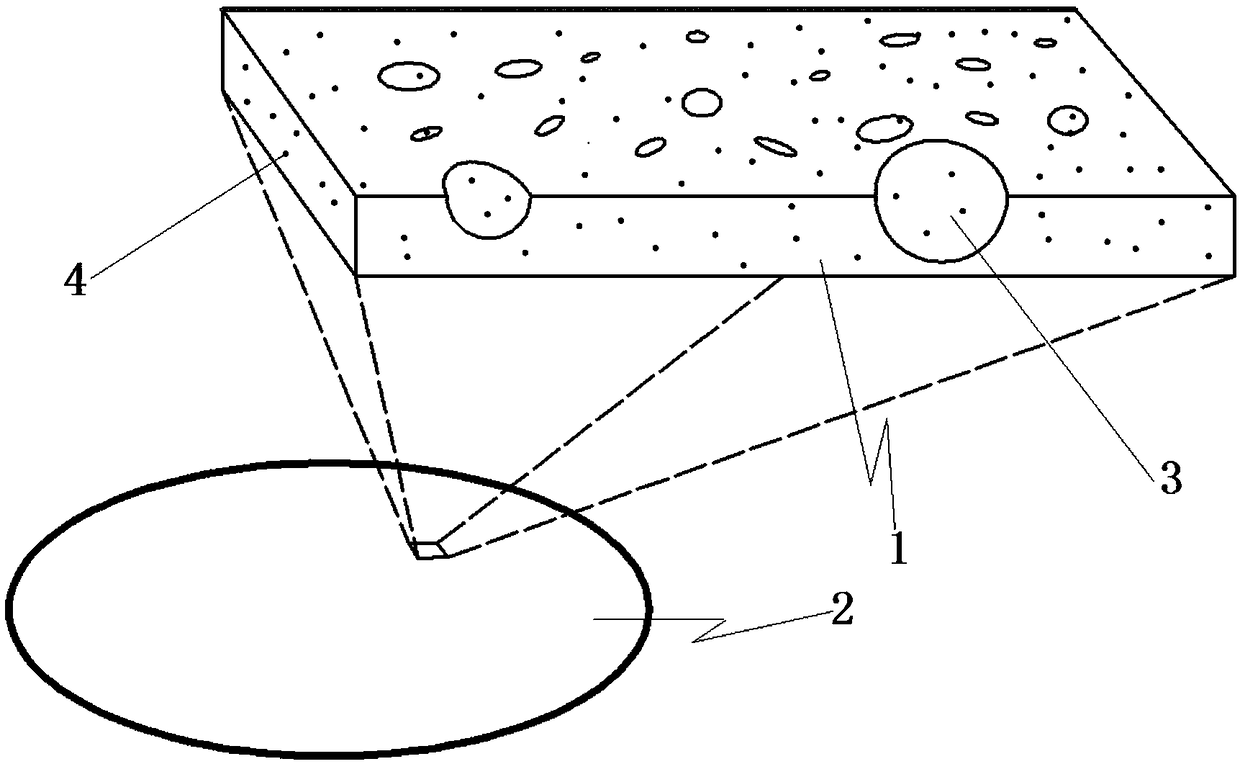

[0035] Such as figure 1 As shown, a perovskite patterned membrane realized by phase separation method, the membrane body is attached to the glass substrate at the macroscopic level, and the perovskite quantum dots are dispersed inside the membrane body at the microscopic level, and the patterned micropores are inlaid and buried. in the diaphragm body. The diaphragm body is a thin film made of high molecular polymer.

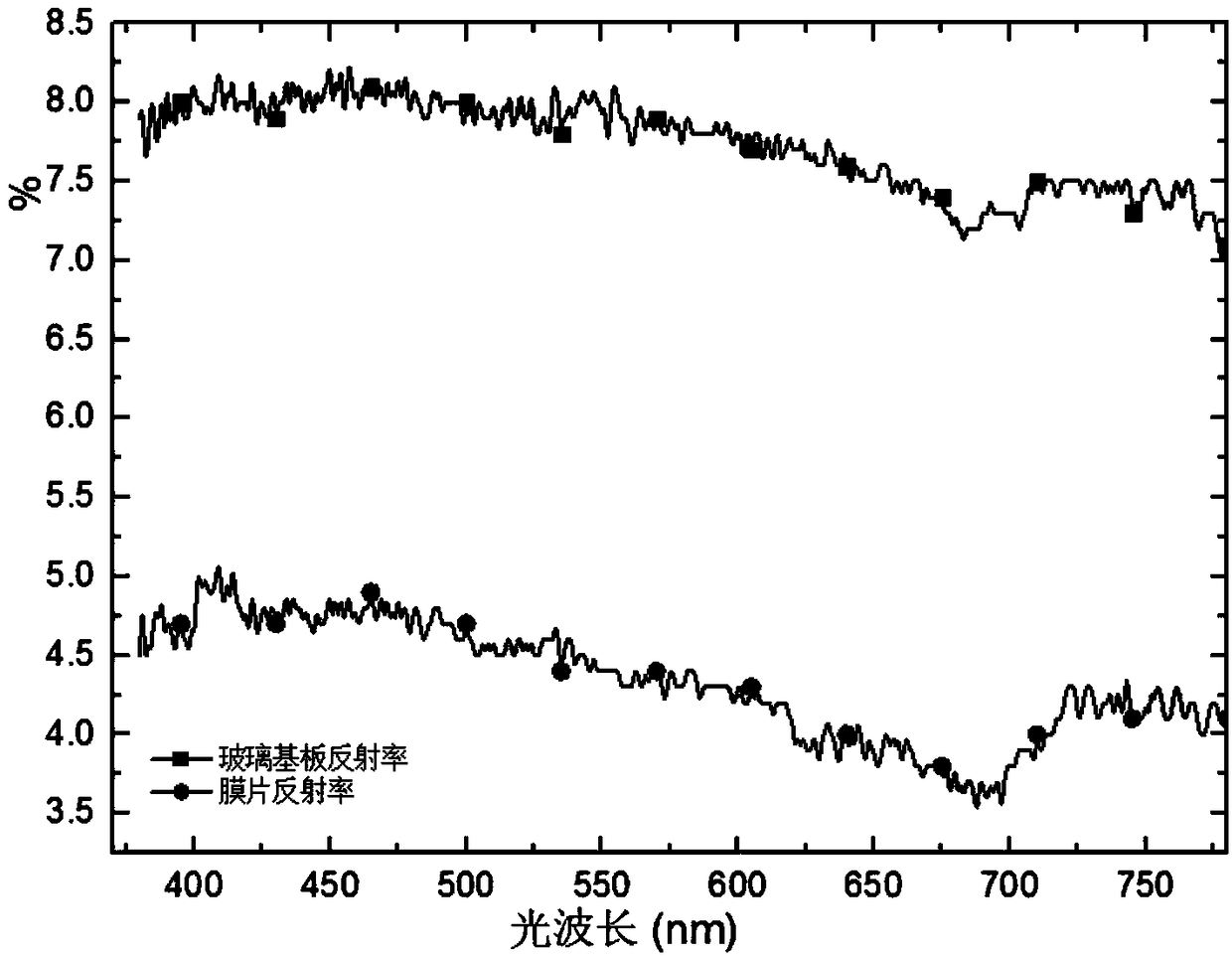

[0036] image 3 Measured by RF-6000 fluorescence spectrophotometer. Figure 4 Photographed by SEM electron microscope S3700 with a magnification of 9000 times.

[0037] A perovskite patterned diaphragm realized by phase separation method, comprising: a diaphragm body, patterned micropores are etched on the diaphragm body, perovskite quantum dots are dispersed inside the diaphragm body; the diaphragm body is polymer Films made of polymers. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com