A method for applying prestress to a tube bundle or panel of a photothermal heat absorber

A technology of prestressing and heat absorber, which is applied in the application of prestress of single-side heated photothermal heat absorber, tube bundle or tube panel prestress of photothermal heat absorber, and can solve the problem of large thermal stress and heat absorber Problems such as low peak heat flux, to achieve the effect of easy process control, reliable method and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

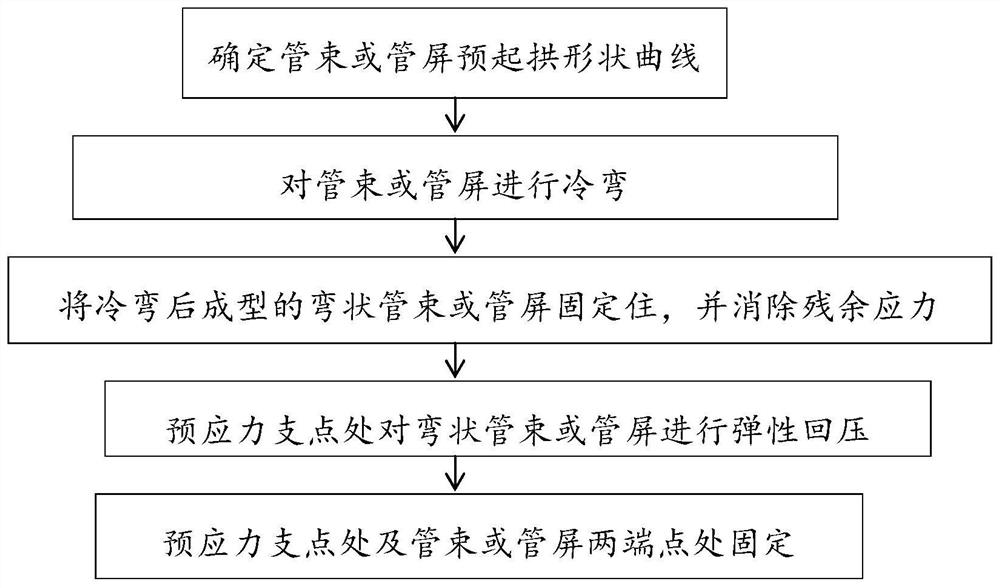

Method used

Image

Examples

example 1

[0101] The CFD software of this example 1 uses ANSYS Fluent 14.5

[0102] FEA software adopts ANSYS Mechanical 14.5

[0103] This example uses a tube bundle to explain the design method and prestress application method of the prestressed tube bundle or tube panel pre-arched shape of the solar thermal absorber of the present invention. where the allowable stress of the material at the operating temperature [σ] t = 280MPa.

[0104] The design process of the specific pre-arching curve is as follows:

[0105] A Solve the tube bundle temperature field under working conditions

[0106] Specifically, according to the actual heat flux density input and medium flow rate of the tube wall of the photothermal absorber, the temperature field of the tube bundle under working conditions is calculated through the fluid dynamics (CFD) analysis software;

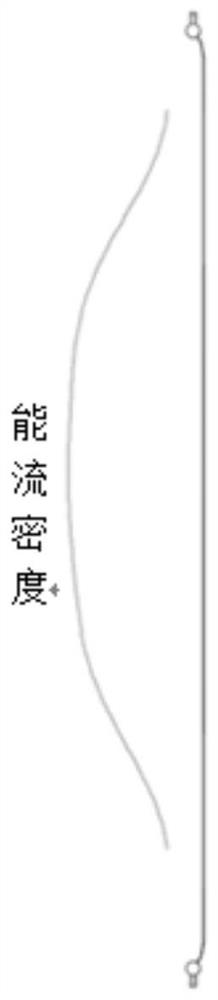

[0107] figure 2 This is the energy-flux density diagram simulated in Example 1 without considering the shape of the tube bundle and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com