Plant equipment management system and method

A factory equipment and management system technology, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve problems such as inconsistent system types, serious safety accidents, complex automation equipment and machine safety management environment, etc., to solve data Difficult collection and difficult management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

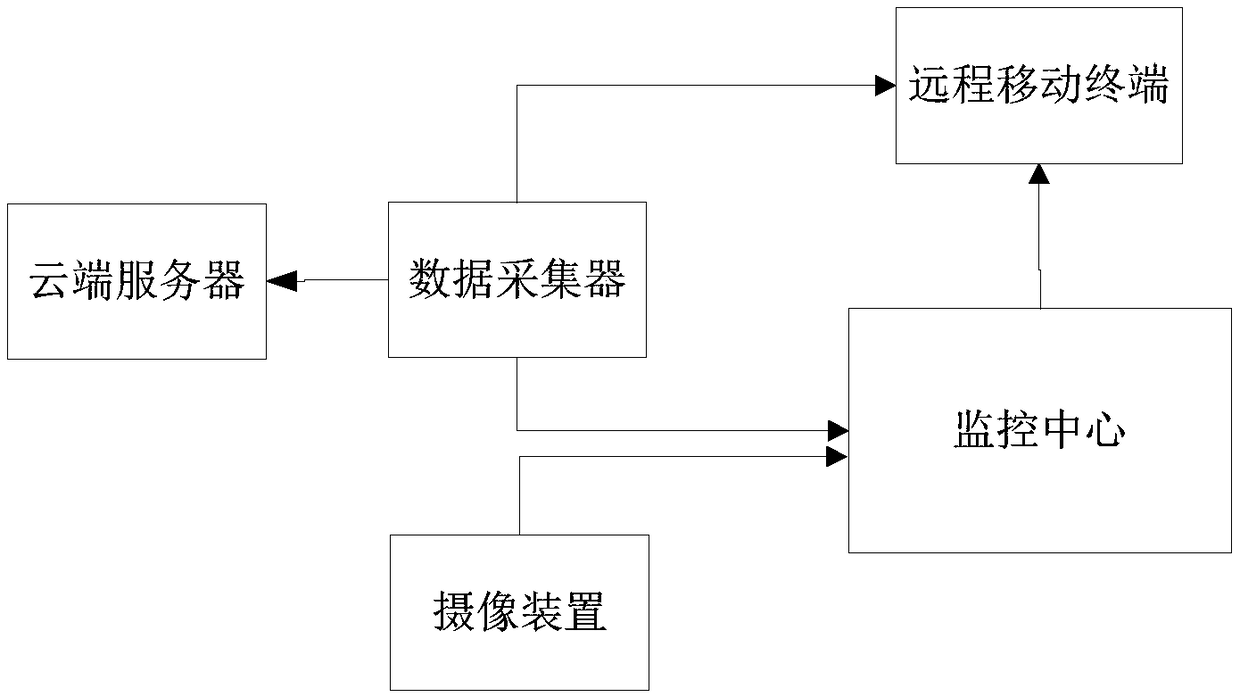

[0028] This example provides a factory equipment management system, its schematic diagram is as follows figure 1 As shown, it includes a data collector, a camera and a monitoring center, wherein the data collector and the camera are respectively connected to the monitoring center by signals.

[0029] The outstanding advantage of the data collector in this example is that it can collect data from different types of devices. For example, the data collector in this example can not only collect data of the Profitnet IO communication protocol, but also collect data of the DeviceNet communication protocol.

[0030] Specifically, the data collector in this example integrates collection instructions of several communication protocols. For example, the storage module of the data collector stores: collection instructions for Siemens brand equipment, collection instructions for Mitsubishi brand equipment, and collection instructions for Omron brand equipment. Instructions, and collection...

Embodiment 2

[0043] Based on the first embodiment, this example provides a factory equipment management method, which specifically includes the following steps.

[0044] S1: Set collection instructions for several communication protocols.

[0045] In order to collect data of various types of equipment in the factory, this example needs to develop collection commands for several communication protocols, including but not limited to: Profitnet IO, EchetCat, DeviceNet, and EtherNet / IP. It should be noted that for open-source communication protocols, it is only necessary to integrate the acquisition command program of the corresponding communication protocol into the data collector. If it is a non-open-source communication protocol, it is necessary to first collect The instructions are decoded, and then the decoded collection instructions are integrated into the data collector. Therefore, in order to collect data from different types of equipment, it is necessary to develop a variety of collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com