Abrasion resistant detection device of leather product

A detection device and technology for leather products, applied in the direction of measuring devices, wear resistance testing, instruments, etc., can solve the problems of inaccurate leather wear resistance, low detection accuracy, and accurate detection of leather wear resistance, so as to ensure accuracy High reliability, accurate test results, and reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

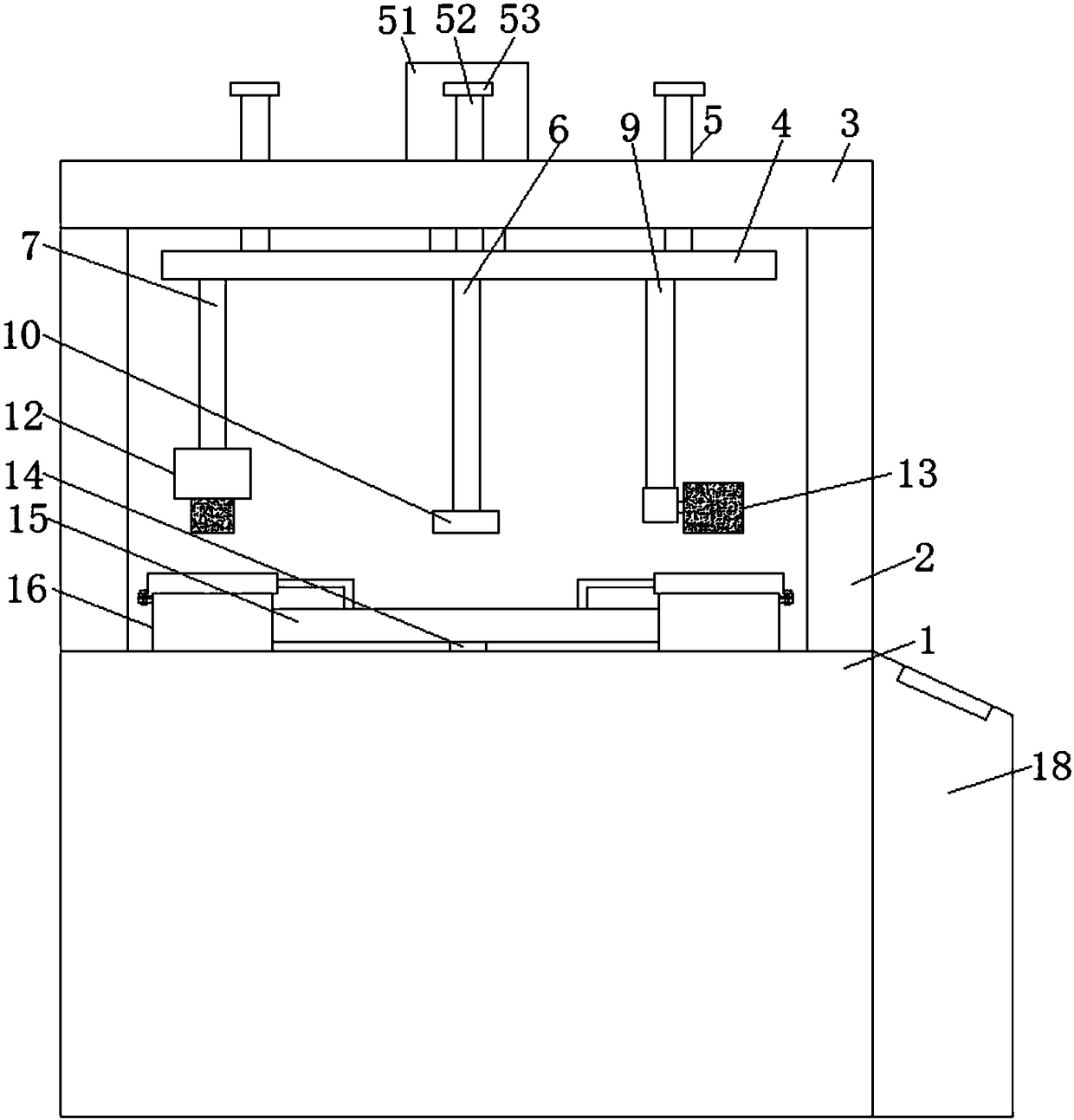

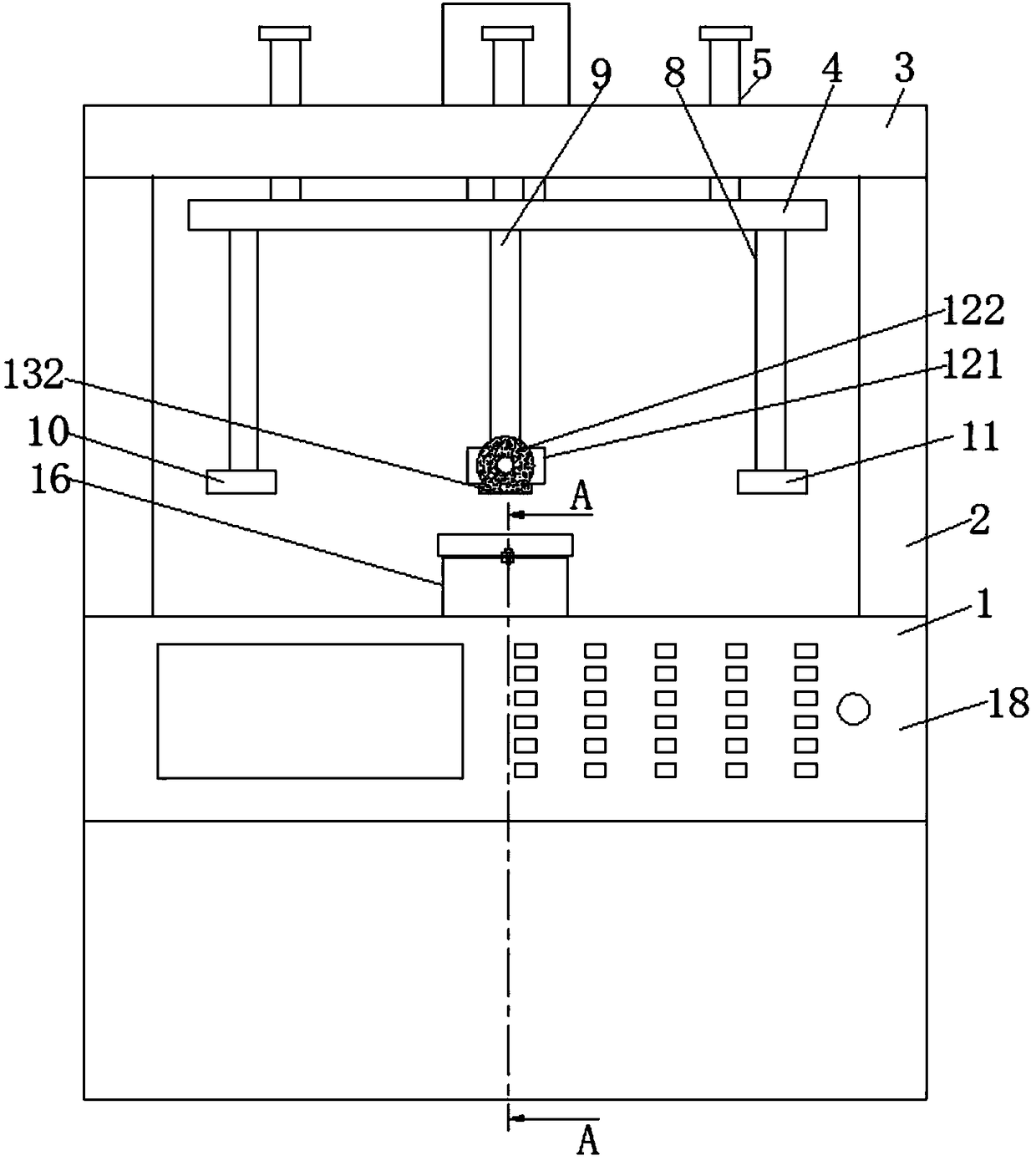

[0028] refer to figure 1 , 2 , 5, 6, 7 and 8, a wear-resistant detection device for leather products, including a detection platform 1, four groups of support rods 2 are vertically arranged on the detection platform 1, and the ends of the four groups of support rods 2 away from the detection platform 1 are provided with Top plate 3, the side of top plate 3 close to detection platform 1 is provided with lifting plate 4, is provided with lifting device 5 between lifting plate 4 and top plate 3, and lifting device 5 comprises electrohydraulic cylinder 51, guide bar 52 and limit plate 53 and Spring, electric hydraulic cylinder 51 is installed in the top center of top plate 3, and the piston rod in electric hydraulic cylinder 51 is vertically connected with lifting plate 4, and the outside of electric hydraulic cylinder 51 is provided with four groups of guide rods 52, and one end of four groups of guide rods 52 Connected vertically with the lifting plate 4, the ends of the four g...

Embodiment 2

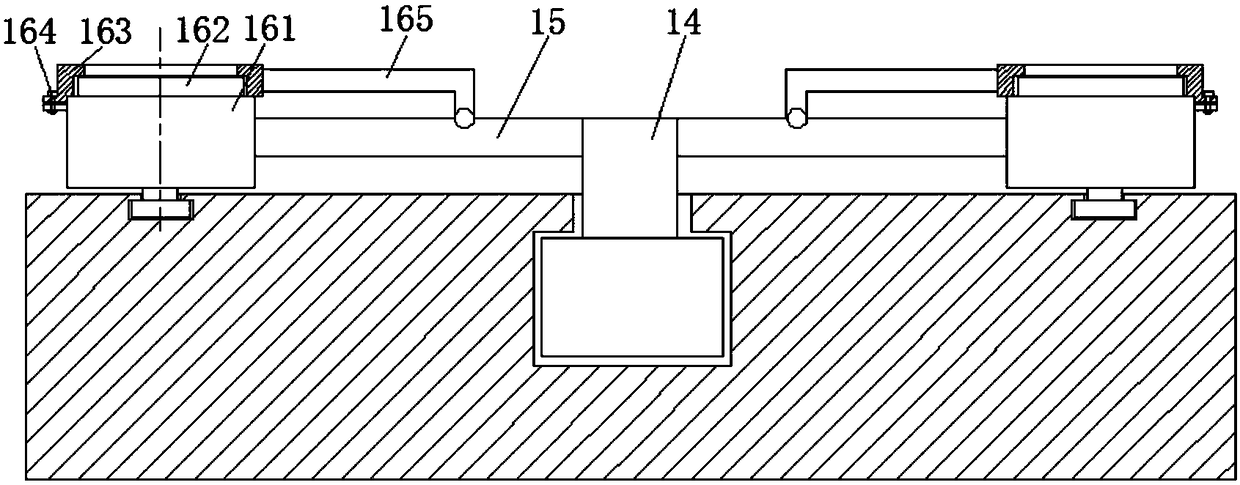

[0031] refer to figure 1 , 3And 4, leather fixing device 16 comprises movable seat 161, boss 162, pressure ring 163, connecting screw rod 164 and connecting rotating rod 165, and guide slider 17 is installed vertically with the center of the bottom of movable seat 161, and movable seat 161 is away from guide slider One end of 17 is provided with boss 162, and the outer side of boss 162 is engaged with pressure ring 163, and pressure ring 163 is hinged with moving seat 161 by hinge, and one side of pressure ring 163 is connected with rotation arm 15 by connecting rotating rod 165, The side of the pressure ring 163 away from the connecting rod 165 is connected with the moving seat 161 through a connecting screw 164 .

[0032] When fixing the leather, first unscrew the connecting screw 164, then open the pressure ring 163, make it rotate at one end connected with the rotating rod 165 and the rotating arm 15, spread the leather on the boss 162, and then press the pressure ring 63...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com