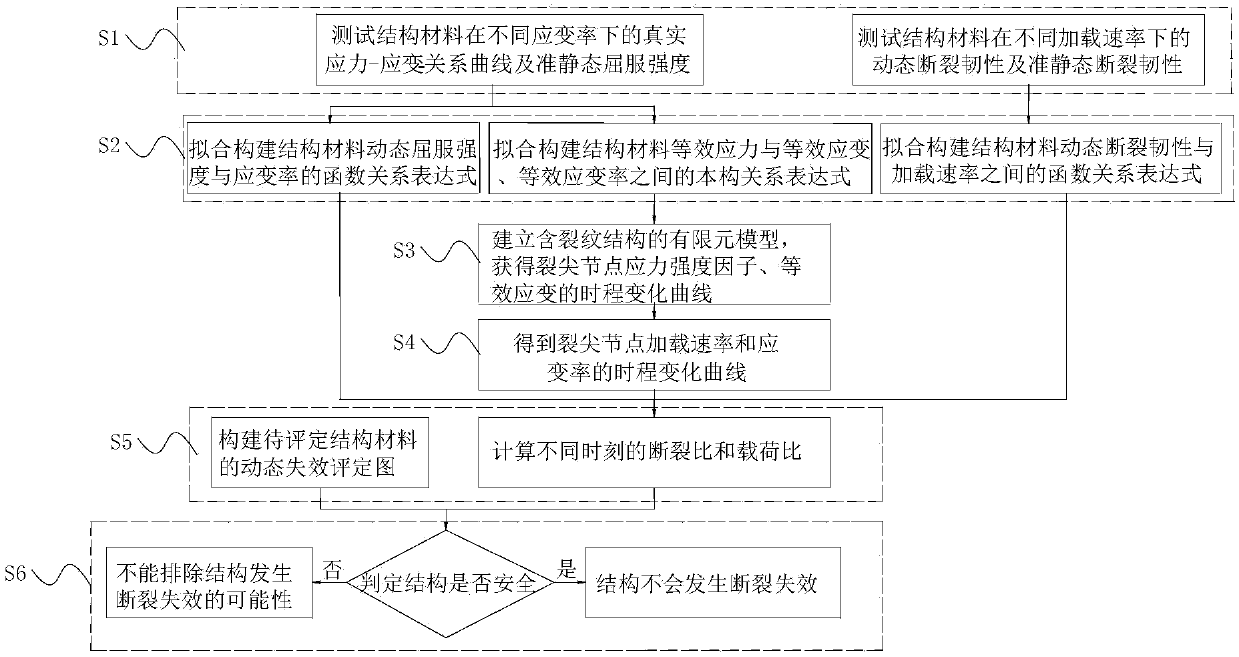

Assessment method of dynamic fracture containing crack-like defect structure

A defect structure and dynamic technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of non-fracture failure evaluation, etc., and achieve the effect of wide application range and clear physical meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0033] The present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the following examples are only for illustrative purposes, but do not limit the scope of the present invention. The specific implementation example is as follows:

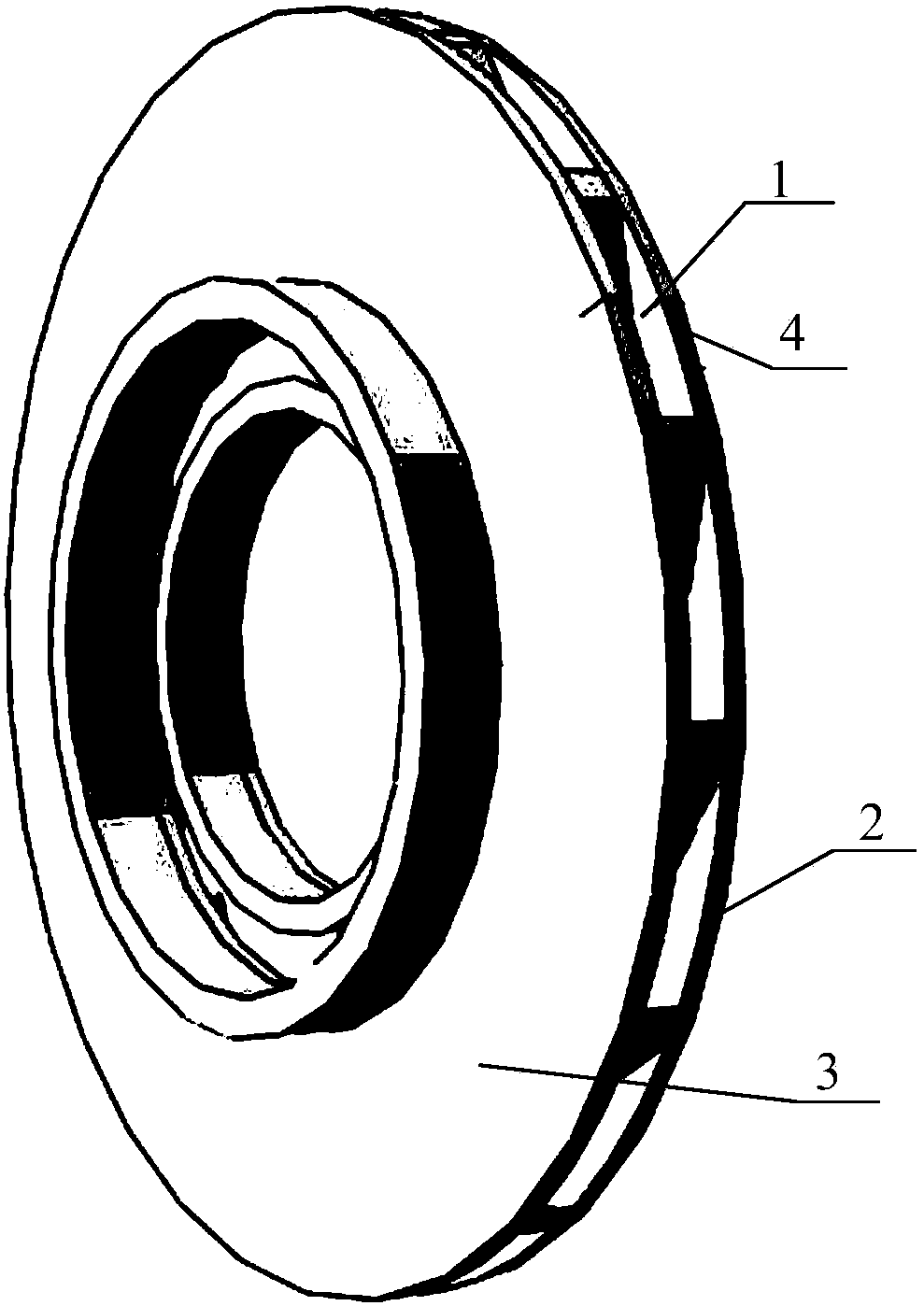

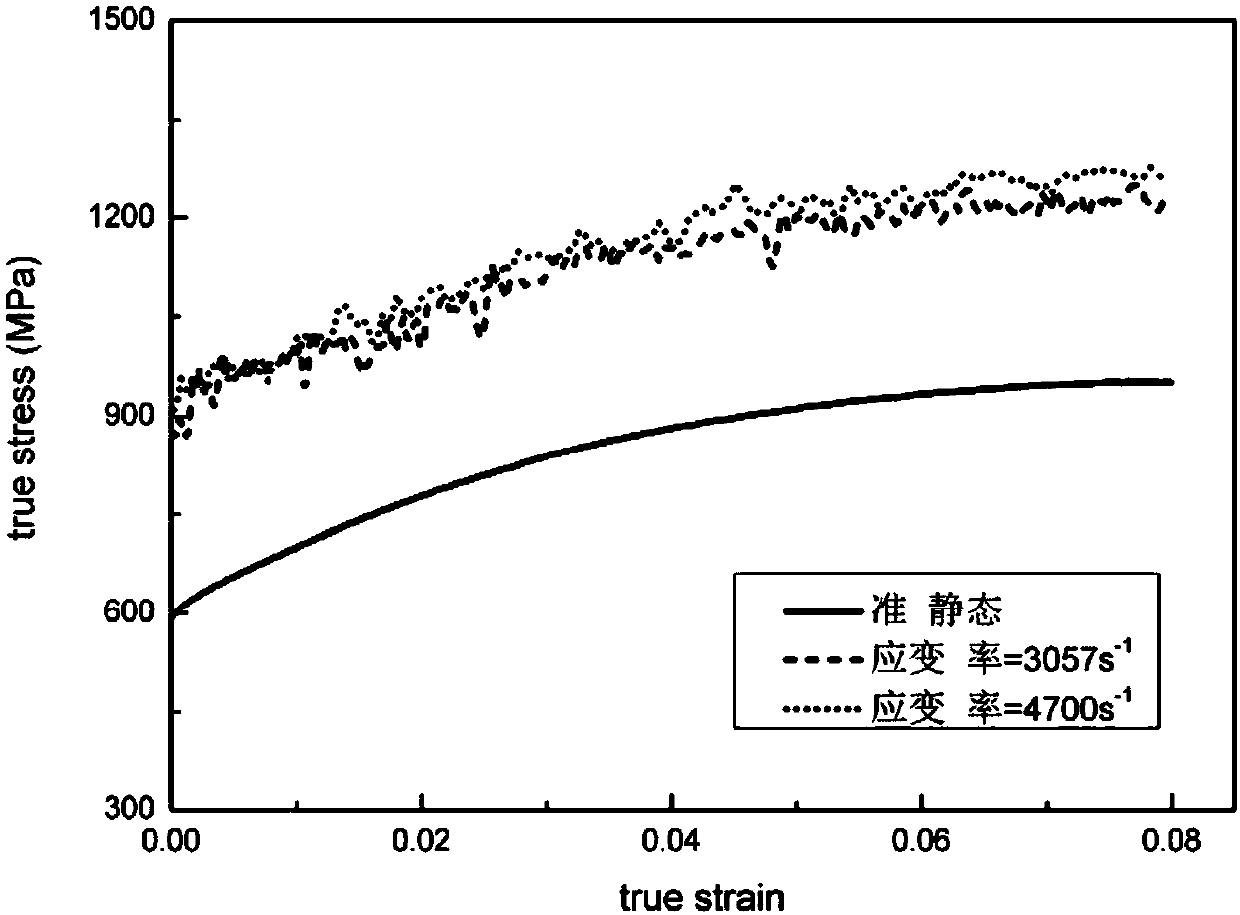

[0034] For a steel impeller, the diameter of the inner hole and the outer hole are 150mm and 400mm respectively. The impeller has 15 blade passages and the speed is 10000r / min. There is a radial crack 1 on the edges of the impeller disk 2 and the wheel cover 3, and the depth of the crack 1 is 15mm. Assuming that the edge position of crack 1, namely the rubbing position 4, has a dynamic rubbing load in the reverse rotation direction, the relationship between the load F and the acting time t is F=F max cos(πt / T-π / 2)), where T=1×10 -4 s, F max = 1×10 3 N. In order to assess whether the impeller will break and fail under the action of a specific dynamic rubbing load, the method pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com