Cloth drying device

A cloth drying and drying room technology, applied in the field of cloth drying and textile, can solve problems such as economic loss and easy damage, and achieve the effect of accelerating heat dissipation, avoiding cloth damage and achieving good drying effect.

Active Publication Date: 2018-06-29

NINGBO WENZE TEXTILE CO LTD

View PDF11 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When drying, in order to ensure a good drying effect, generally a higher temperature is used to dry the cloth, and the heating element is fixed, and the cloth is driven by the transmission mechanism to pass under the heating element, but the water on the cloth near the outlet All the parts have evaporated, but the fabric is still at high temperature at this time, and the fabric used to make clothes is generally made of cotton, hemp, wool, silk, various synthetic fibers, etc. These materials are extremely high under the action of high temperature. Easily damaged, causing economic loss

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

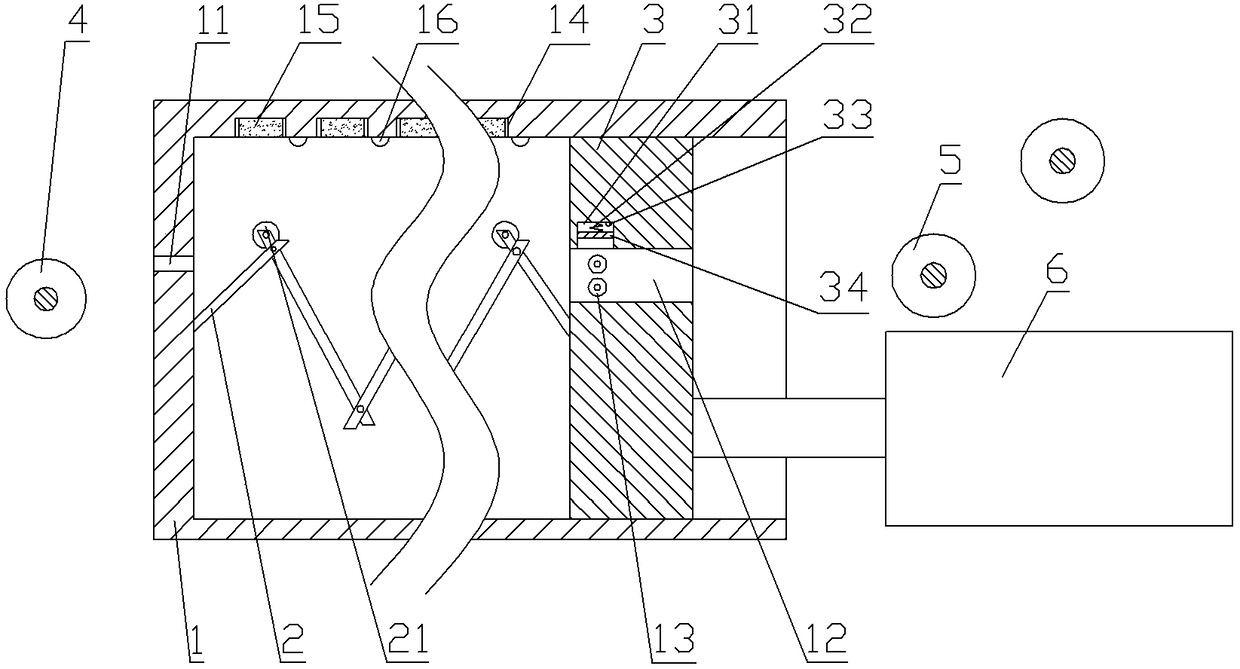

The invention relates to the field of textiles and particularly discloses a cloth drying device which comprises a rack, a drying mechanism and a feeding mechanism, wherein the drying mechanism comprises a drying room, a piston, heating parts and supporting assemblies; a discharging channel is arranged at one end of the drying room; the other end of the drying room is open; a feeding channel is arranged on the piston; a sliding chute is arranged on the side wall of the feeding channel; a spring and a sliding block are arranged in the sliding chute; a winding switch is arranged in the sliding chute; the heating parts are fixed at the top of an inner cavity of the drying room; the supporting assemblies comprise a plurality of connecting rods; evert two adjacent connecting rods are hinged; theend parts of the connecting rods are hinged with the side wall of the drying room and the piston; the feeding mechanism comprises a motor, a winding roll and a hydraulic cylinder; the winding roll can be driven by the motor to rotate; the motor can be started by releasing the winding switch; and the piston can be driven by the hydraulic cylinder to slide. By adoption of the cloth drying device, the positions of cloth and the heating parts can be adjusted, thereby adjusting the temperature of the cloth and protecting the cloth against damage.

Description

technical field [0001] The invention relates to the textile field, in particular to the field of drying cloth. Background technique [0002] Clothes are indispensable in people's daily life. Clothing is cut and sewn from cloth, and the quality of cloth directly affects the warmth retention and service life of clothing. In order to improve the aesthetics of clothes, cloths of different colors are needed in the production process of clothes, so the cloths also need to be dyed. Traditional cloths are artificially dyed and then dried under natural conditions, but natural drying takes a lot of time, and the cloth The production efficiency is low, so manual drying of cloth is generally used now. [0003] After the cloth is dyed, the cloth is sent to the drying room, and a heating device is fixed in the drying room. The heating device increases the temperature of the cloth, and then evaporates the water on the cloth after absorbing the heat. When drying, in order to ensure a good...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): F26B13/08F26B23/00F26B25/00

CPCF26B13/08F26B23/00F26B25/00

Inventor 孙文清

Owner NINGBO WENZE TEXTILE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap