Agricultural product low-temperature negative-pressure drying and crushing integrated method and system

A technology for low-temperature negative pressure and agricultural products, which is applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc. It can solve the problems of unstable temperature control, high cost, and low processing efficiency, so as to ensure effective nutrition, The effect of not destroying nutrients and avoiding rot and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

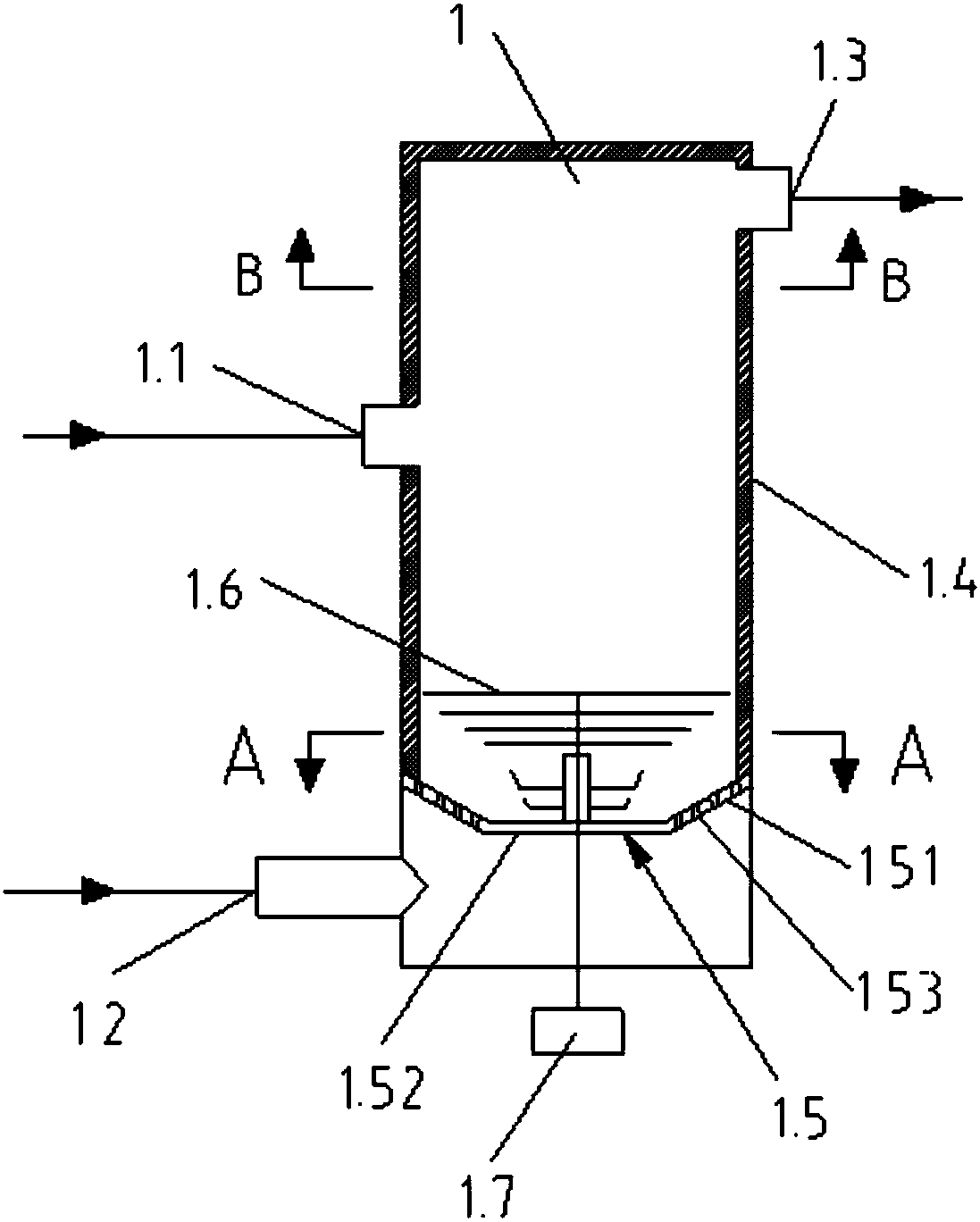

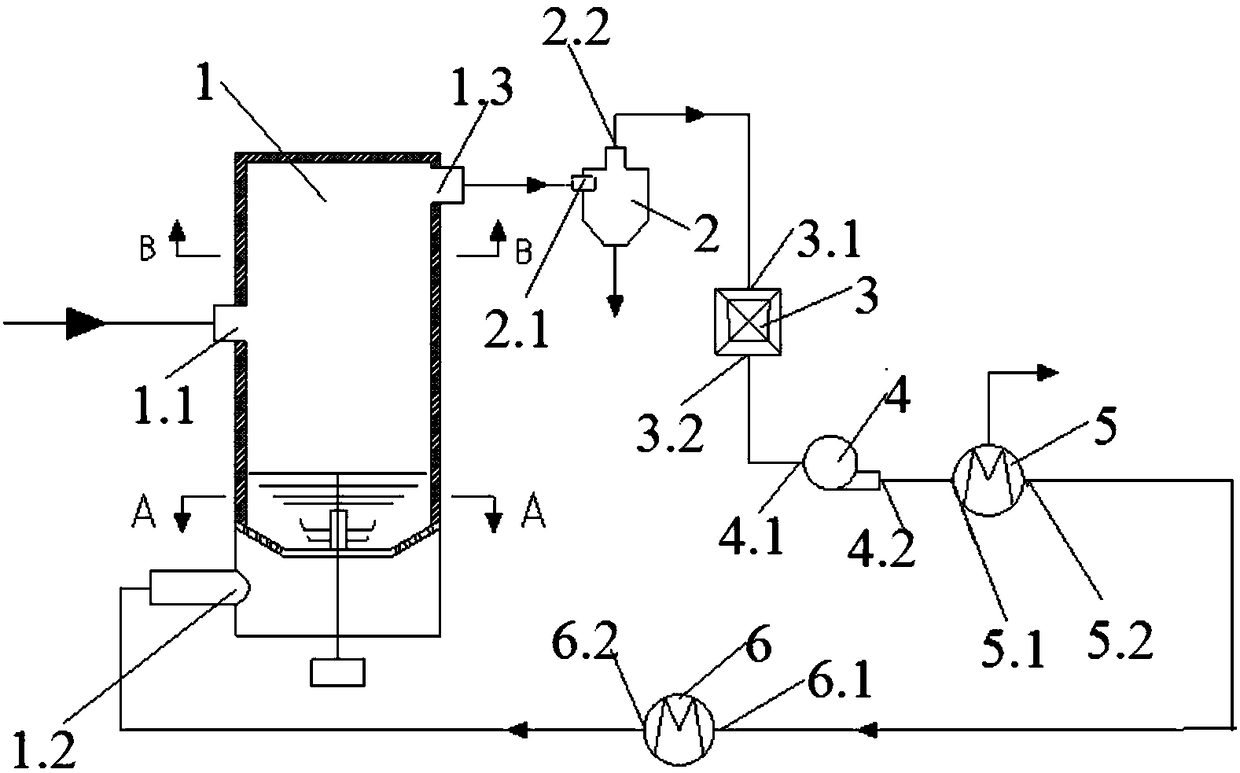

[0031] Such as figure 1 The low-temperature negative-pressure drying and crushing integrated system for agricultural products shown includes a low-temperature negative-pressure drying furnace 1, a cyclone separator 2, a dust collector 3, a vacuum pump 4, a condenser 5 and a gas heater 6, and a low-temperature negative-pressure drying furnace 1 An agricultural product feed inlet 1.1 for entering agricultural products is provided in the middle of the middle, an air inlet 1.2 for heating carrier gas is provided at the bottom of the low-temperature negative pressure drying furnace 1 along the outer wall tangentially, and an air inlet 1.2 for heating carrier gas is provided on the bottom of the low-temperature negative pressure drying furnace 1 along the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com