Self-locking chain wheel and self-locking method thereof

A self-locking, sprocket technology, applied in belts/chains/gears, portable lifting devices, rigid shaft couplings, etc., can solve the problems of damaged transmission shafts, difficult disassembly, and inability to disassemble, and achieve load capacity The effect of lifting, adapting to a large range, and reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

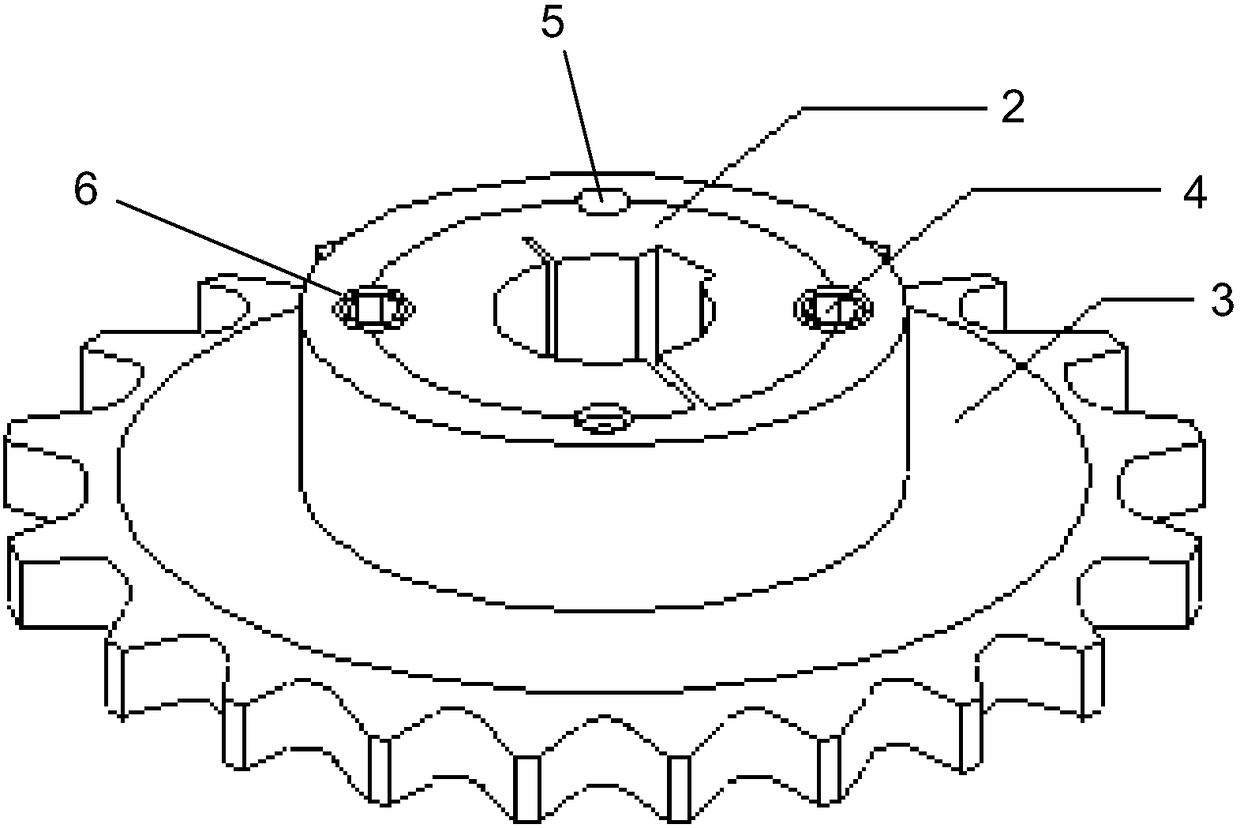

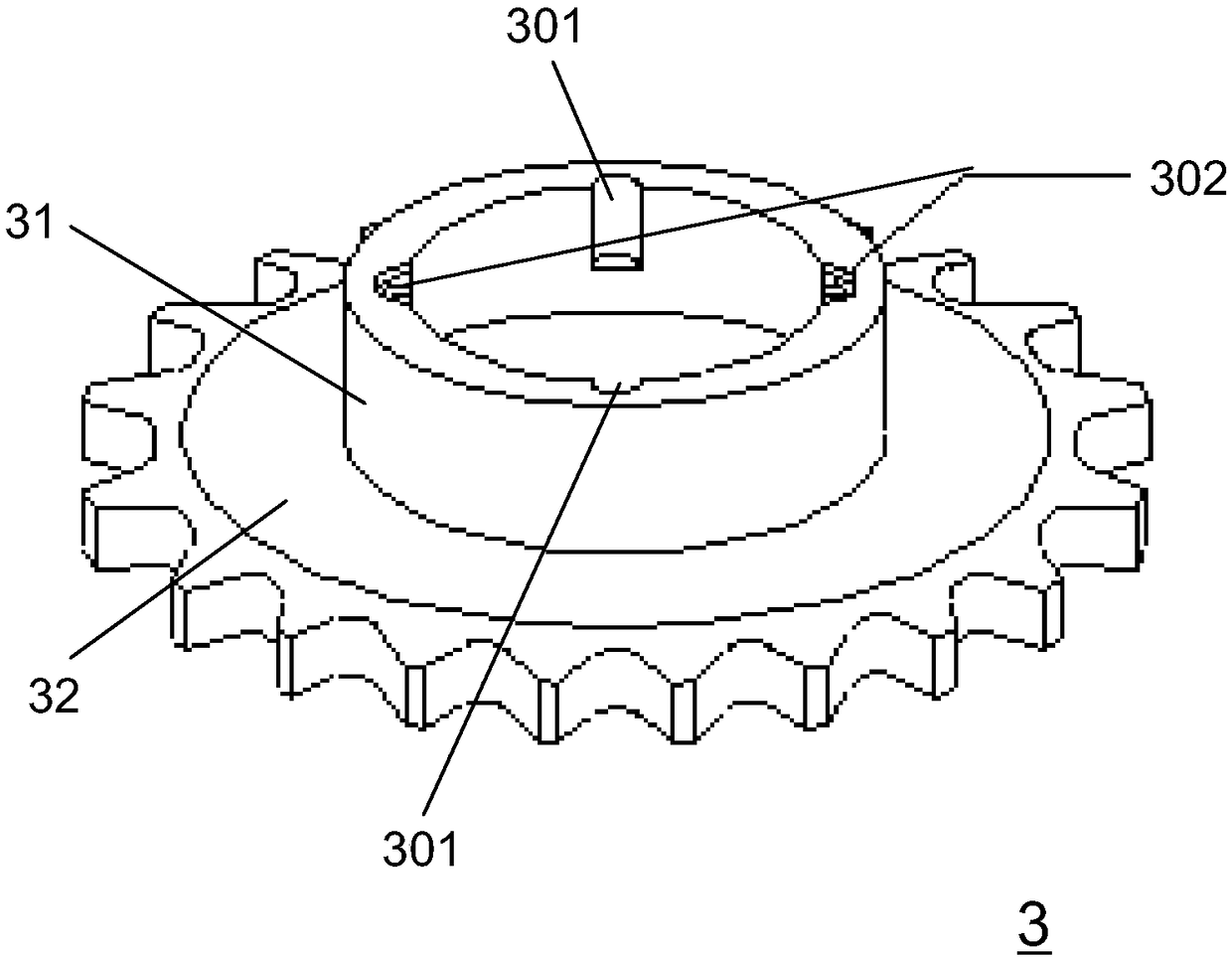

[0029] Please combine Figure 1 to Figure 4 As shown, a self-locking sprocket provided by the present invention is sleeved on the transmission shaft 1, including a locking inner sleeve 2, a gear set 3 and a locking bolt 4, and the locking inner sleeve 2 is set on the gear set 3 and fixed on the transmission shaft 1 through the locking bolt 4.

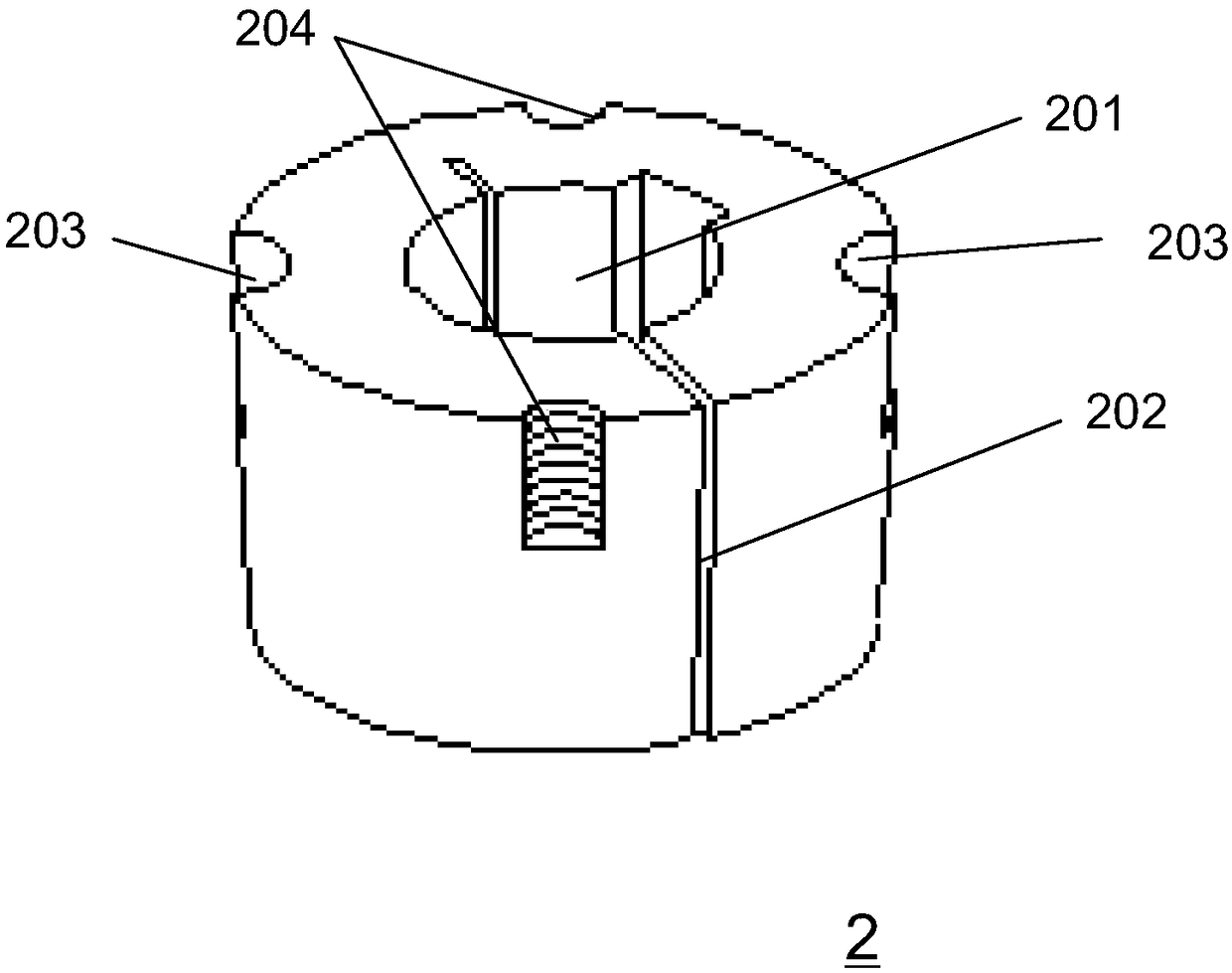

[0030] Preferably, the outer circle of the locking inner sleeve 2 is set to be a cone, and a through hole 201 is provided on the central line of the transmission shaft. The transmission shaft 1 is arranged in the through hole 201, and the locking inner sleeve 2 There is a gap 202 on the top, which is used to reduce the diameter of the inner circle of the locking inner sleeve 2, and to tighten the locking inner sleeve 2, so that the locking inner sleeve 2 can lock the transmission shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com