Damping device and gas injector with a damping device

A gas injector and vibration damping device technology, which is applied in the direction of shock absorbers, friction shock absorbers, solid shock absorbers, etc., can solve the problems of limited vibration damping effect, and achieve the effect of compact storage space, simple and robust structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

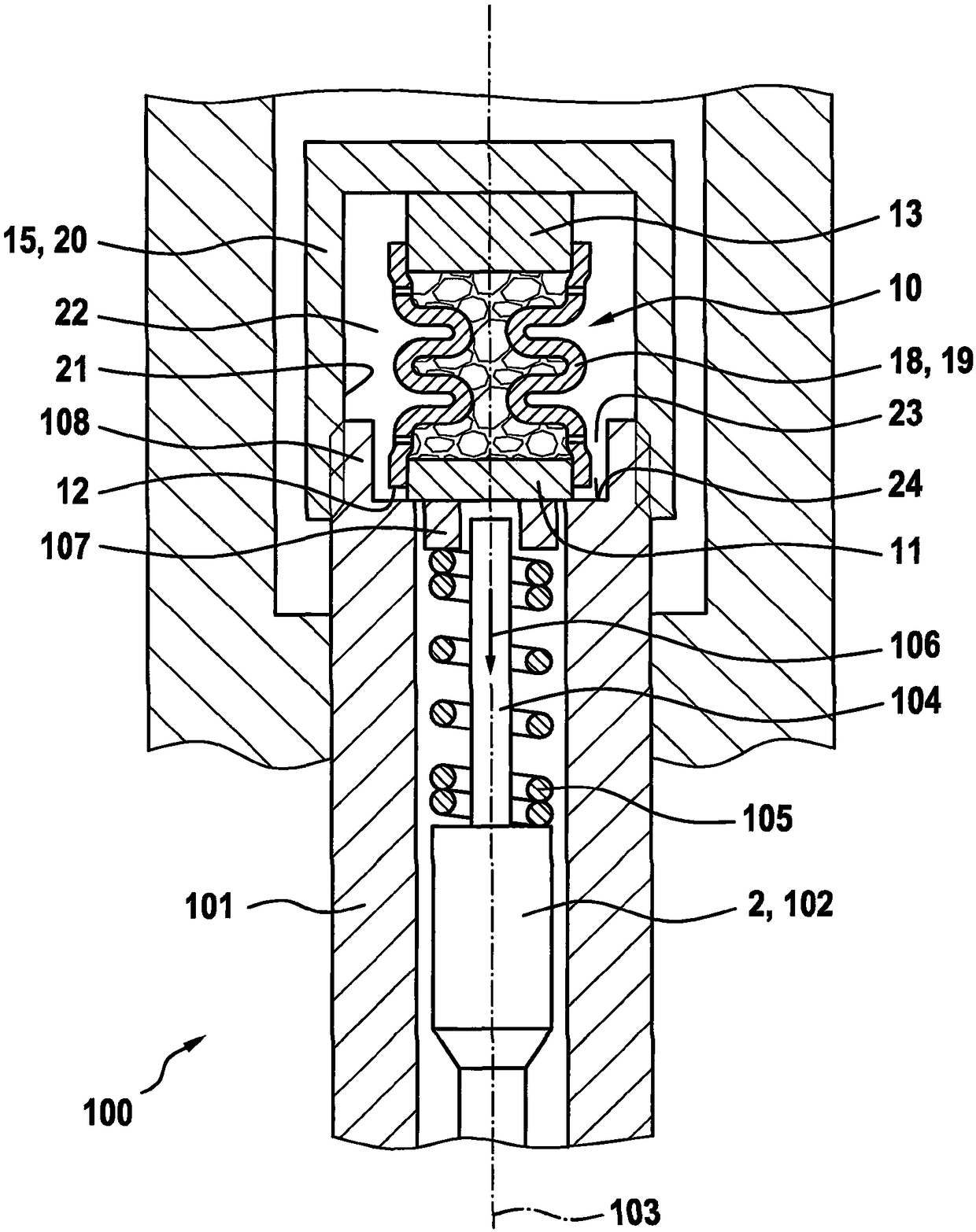

[0022] exist figure 1 The middle area shows a gas injector 100 , such as is provided, in particular in motor vehicles, for at least indirectly injecting gas into a combustion chamber of an internal combustion engine. The gas injector 100 has an injector housing 101 , in which a gas needle 102 is arranged movably in a bore along a longitudinal axis 103 as a movable element 2 . The gas needle 102 is connected at one end to a piston rod 104 which is radially surrounded by a spring element 105 , wherein the spring element 105 is designed as a compression spring and exerts a force acting on the gas needle 102 in the direction of the arrow 106 . . The end side of the spring element 105 facing away from the gas needle 102 rests axially on the damper 10 below the center position of the adjusting washer 107 , the thickness of which can be used to adjust the spring element 105 to act on the gas needle 102 The size of the preload.

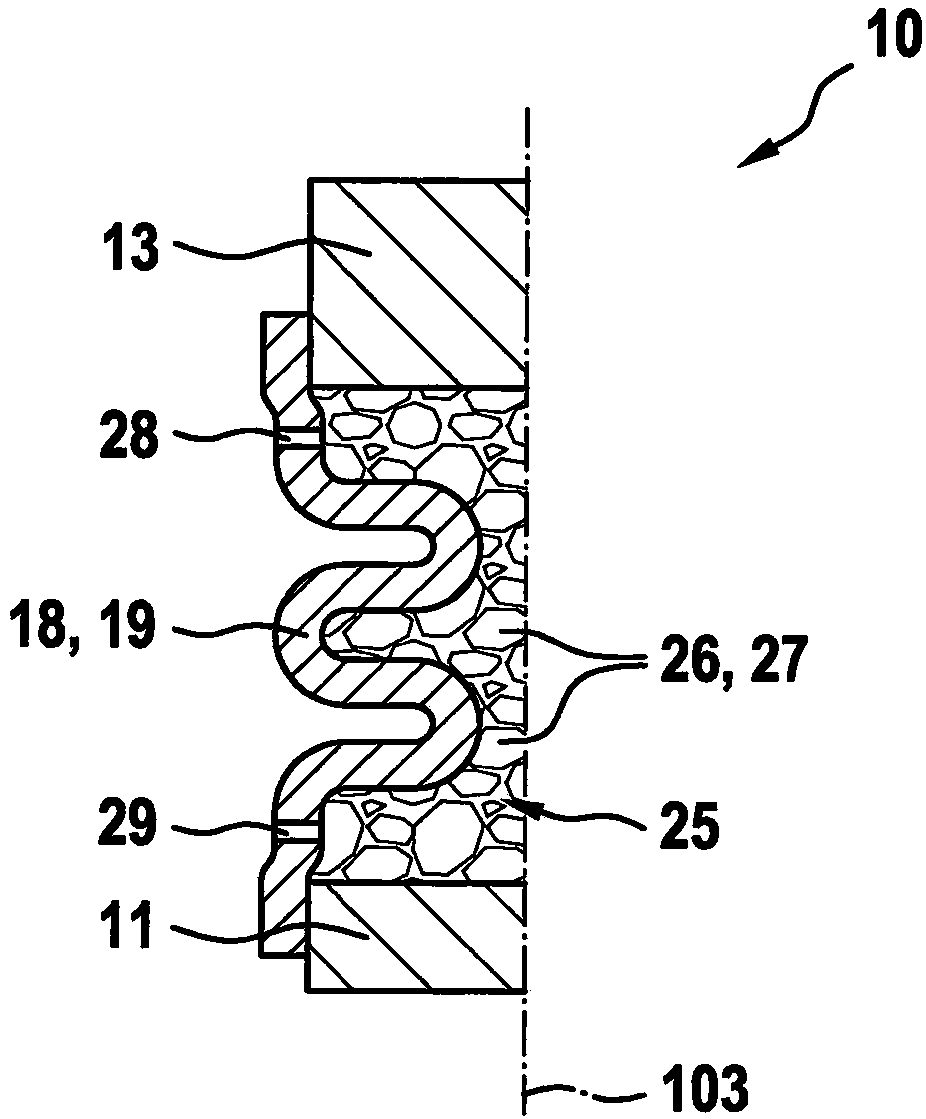

[0023] The damping device 10 has a plate-shaped firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com