Shape memory alloy bearing and assembling method thereof

A memory alloy and bearing technology, which is applied in the field of shape memory alloy joint bearings and its assembly, can solve the problem of affecting the performance of the bearing, the low dimensional accuracy of the inner spherical surface of the bearing outer ring, and the close contact between the inner spherical surface of the bearing outer ring and the outer spherical surface of the bearing inner ring. The degree of fit is not easy to control and other problems, to achieve the effect required by high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

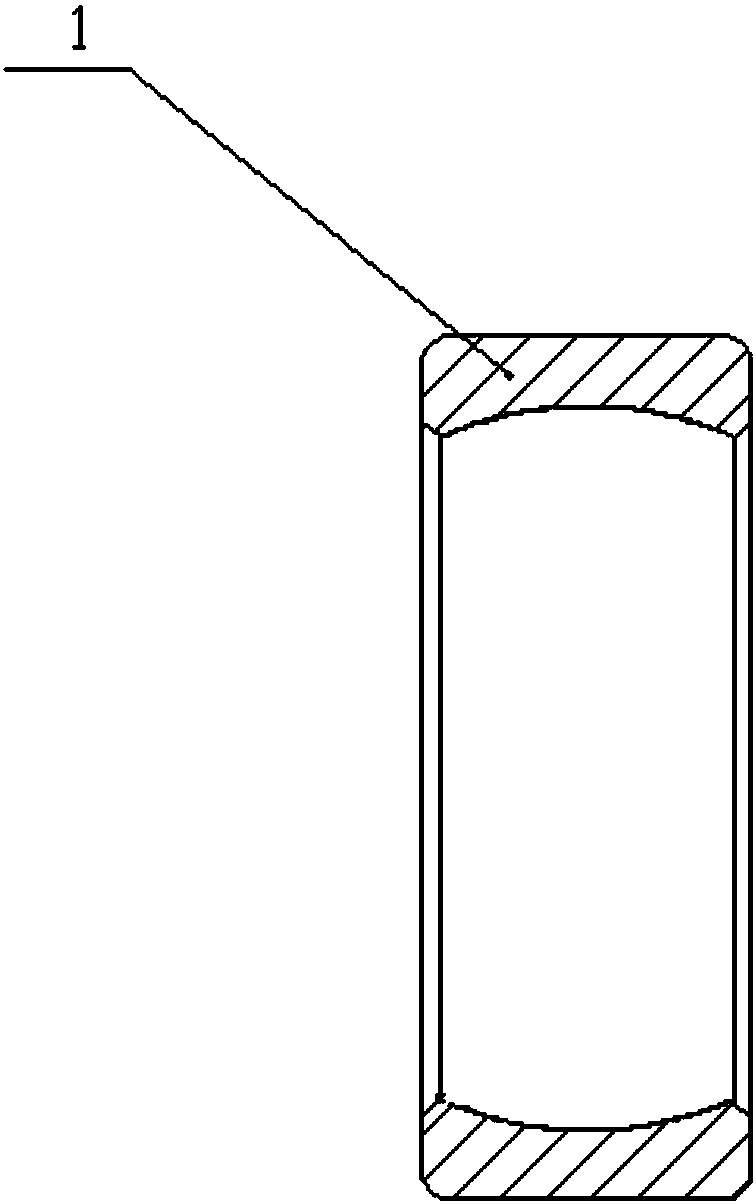

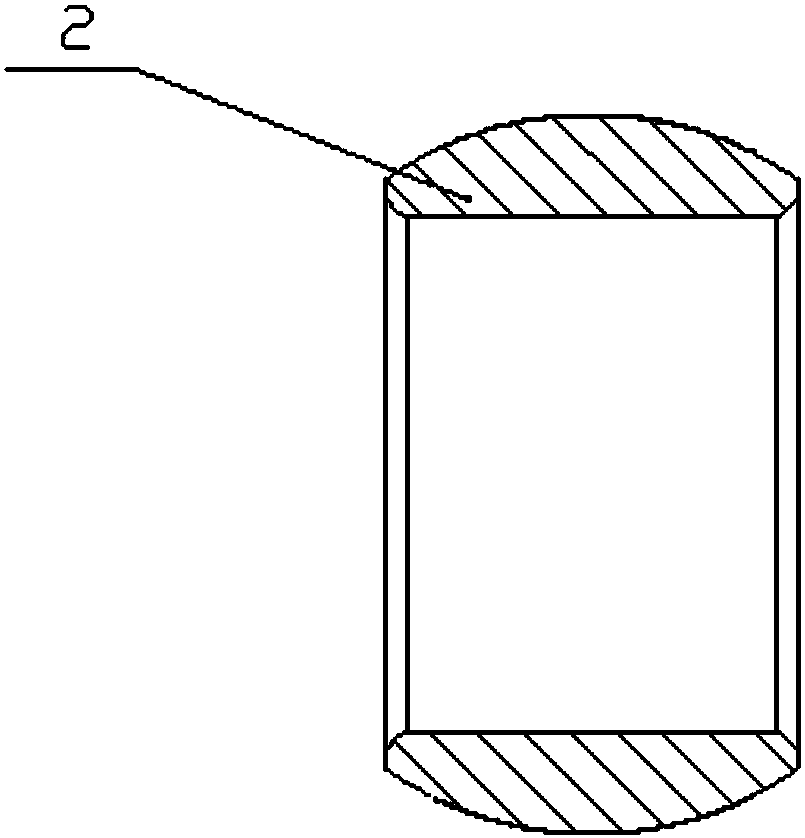

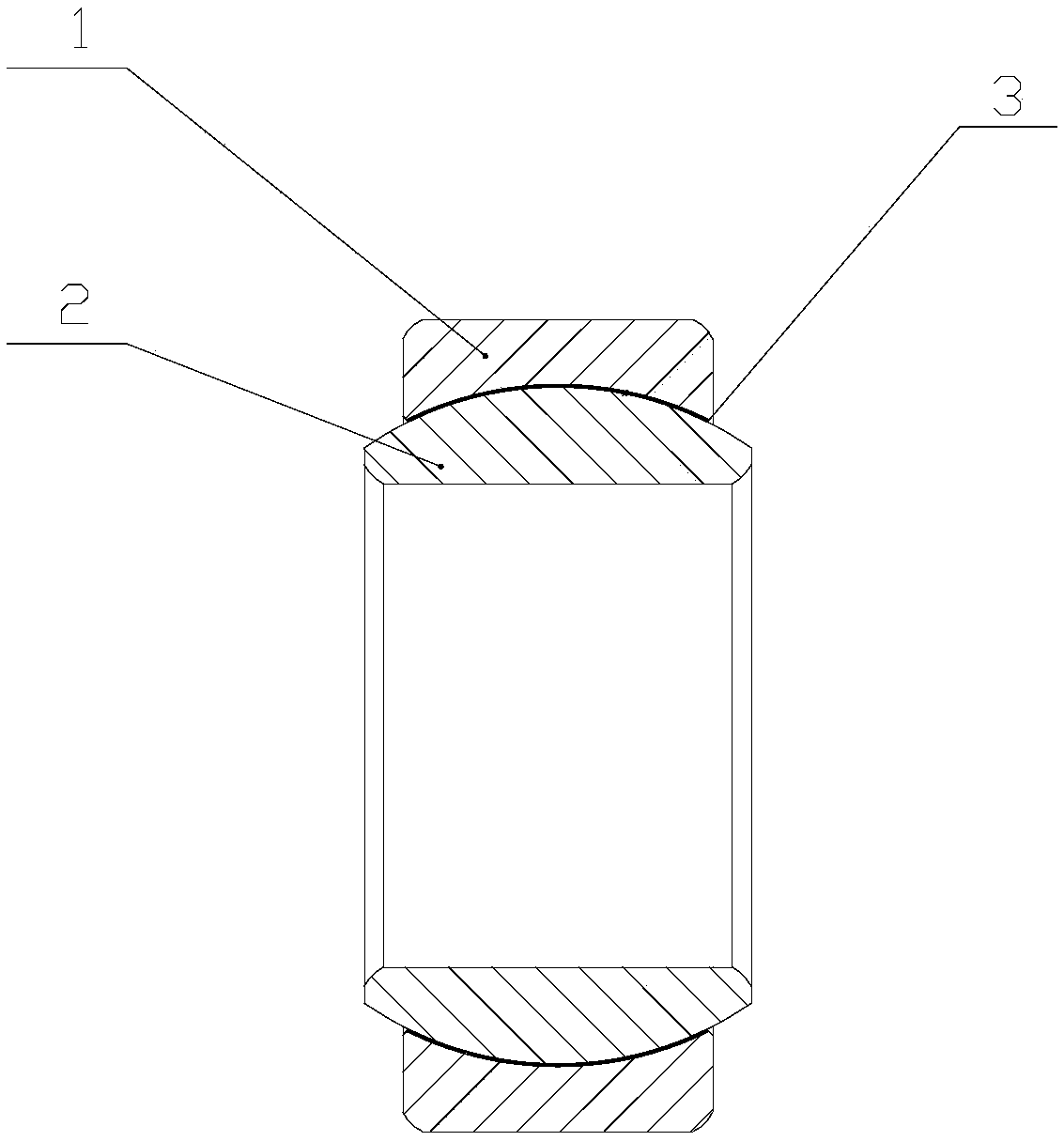

[0060] In this embodiment, this embodiment provides a shape memory alloy joint bearing, which includes a bearing outer ring 1, a bearing inner ring 2 and a self-lubricating layer 3, the bearing outer ring 1 is nested on the outside of the bearing inner ring 2, and the self-lubricating layer The lubricating layer 3 is arranged between the bearing outer ring 1 and the bearing inner ring 2. The bearing outer ring 1 is made of steel, titanium alloy, aluminum alloy or other metal materials, and the bearing inner ring 2 is made of shape memory alloy. The self-lubricating layer 3 Consists of solid self-lubricating materials.

Embodiment 2

[0062] In this embodiment, this embodiment provides a shape memory alloy joint bearing, which includes a bearing outer ring 1, a bearing inner ring 2 and a self-lubricating layer 3, the bearing outer ring 1 is nested on the outside of the bearing inner ring 2, and the self-lubricating layer The lubricating layer 3 is arranged between the bearing outer ring 1 and the bearing inner ring 2, the bearing outer ring 1 is made of shape memory alloy, the bearing inner ring 2 is made of steel, titanium alloy, aluminum alloy or other metal materials, and the self-lubricating layer 3 Consists of solid self-lubricating materials.

Embodiment 3

[0064] In this embodiment, this embodiment provides a shape memory alloy joint bearing, which includes a bearing outer ring 1, a bearing inner ring 2 and a self-lubricating layer 3, the bearing outer ring 1 is nested on the outside of the bearing inner ring 2, and the self-lubricating layer The lubricating layer 3 is arranged between the bearing outer ring 1 and the bearing inner ring 2. Both the bearing outer ring 1 and the bearing inner ring 2 are made of shape memory alloy, and the self-lubricating layer 3 is composed of a solid self-lubricating material.

[0065] Specifically, the preparation / assembly method of any shape memory alloy joint bearing in Examples 1-3 is as follows:

[0066] First, the bearing inner ring 2 is processed and formed; then the bearing outer ring 1 is processed and formed; then, a self-lubricating layer 3 is arranged on the inner surface of the semi-finished product of the bearing outer ring 1, and the bearing inner ring 2 is arranged on the self-lub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com