Turning fixture for once clamping processing of valve

A one-time, turning technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as difficulty in satisfying batch and large-scale production, waste of human and material resources, cumbersome processing process, etc., to achieve a solution The processing process is complex, the operation is convenient and fast, and the effect of reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

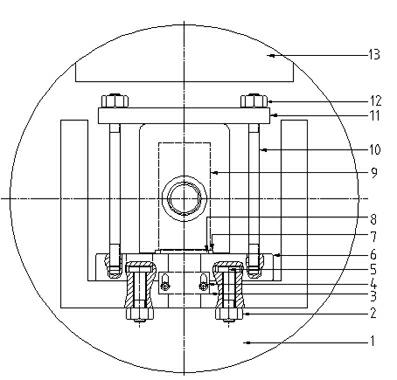

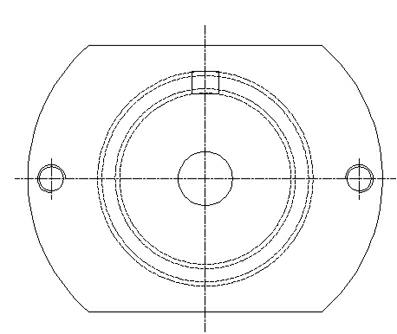

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as Figure 1-4 As shown, the turning fixture includes an angle iron mold 1, a support block 6, a rotating mandrel 8, a correction block 3, a briquetting block 11 and a counterweight 13, and the angle iron mold 1 is integrally cast, and the bottom of the angle iron mold 1 and The back side is vertical, the front of the angle iron mold 1 is processed into a dustpan mouth type, the bottom of the dustpan mouth is provided with two through holes and a middle hole, and a counterweight 13 is arranged on the top of the angle iron mold 1 to balance the rotation, and the two proof faces of the support block 6 are parallel and Symmetrical, a central hole is set on the support block 6, a T-shaped groove is set inside the support block 6, an open groove is set on the upper part of the T-shaped groove, both sides of the correction block 3 are smoothed, two U-shaped groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com