Combined mold for processing gas thrust bearing bump foil of elastic foil sheet

A technology for processing molds and elastic foils, applied in manufacturing tools, presses, etc., can solve the problems that cannot meet the processing requirements of large quantities of multi-form corrugated foils, complex surface morphology of bearing corrugated foils, and is not conducive to processing and production. To achieve the effect of compact structure, low cost and small structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

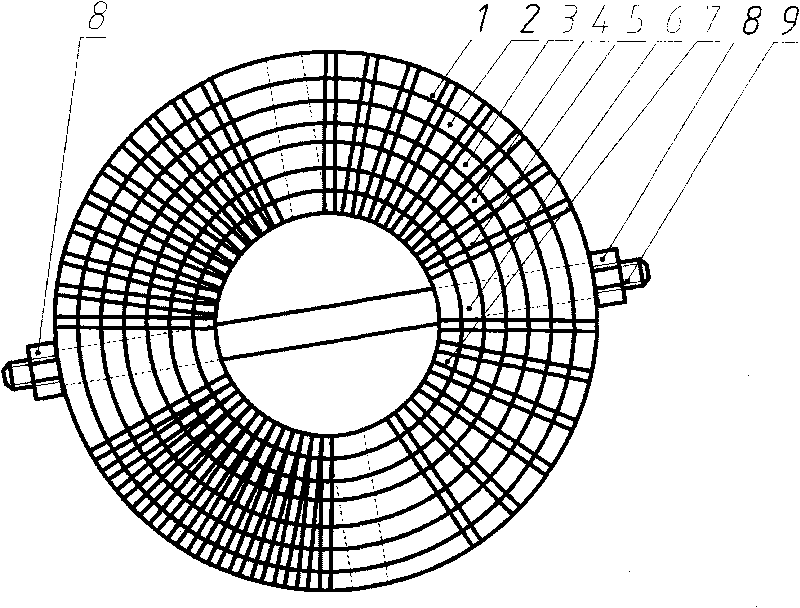

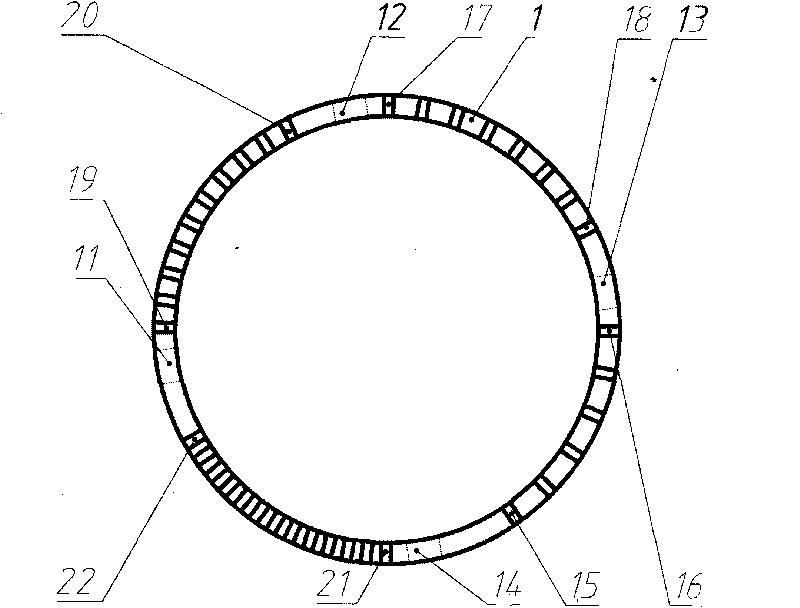

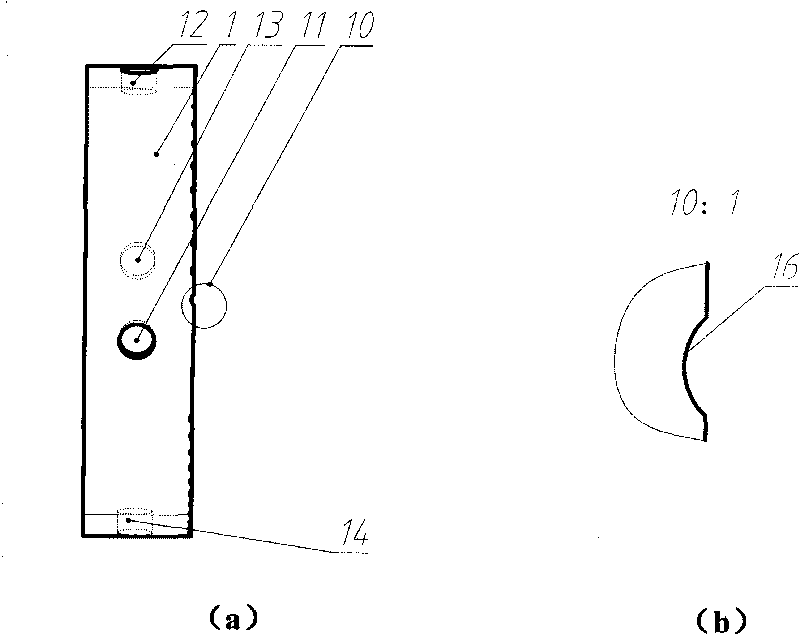

[0024] see figure 1 , 2 , 3 and 4, a combined mold for corrugated foil processing of elastic foil gas thrust bearing, including corrugated foil processing mold ring 1, corrugated foil processing mold ring 1 nested with corrugated foil processing mold ring 2, corrugated foil processing mold ring 2, corrugated foil processing mold ring 1 The corrugated foil processing die ring 2 is nested with a corrugated foil processing die ring 3, the corrugated foil processing die ring 3 is nested with a corrugated foil processing die ring 4, and the corrugated foil processing die ring 4 is nested with a corrugated foil processing die ring 5, Corrugated foil processing die ring 5 is nested with corrugated foil processing die ring 6, corrugated foil processing die ring 6 is nested with corrugated foil processing die ring 7, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com