Embroidery machine

An embroidery machine and machine head technology, which is applied in the field of embroidery machines, can solve the problems of limited installation space and high installation difficulty, and achieve the effect of good synchronization and uniform patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

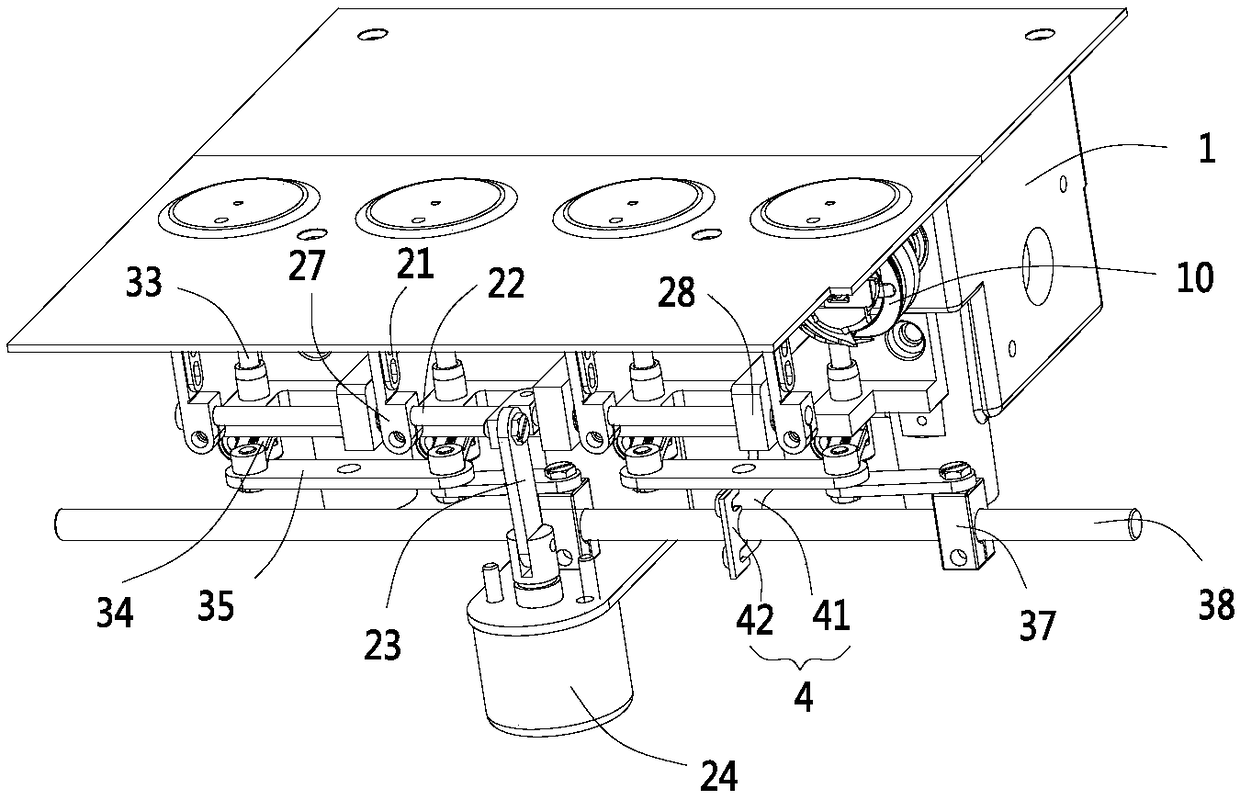

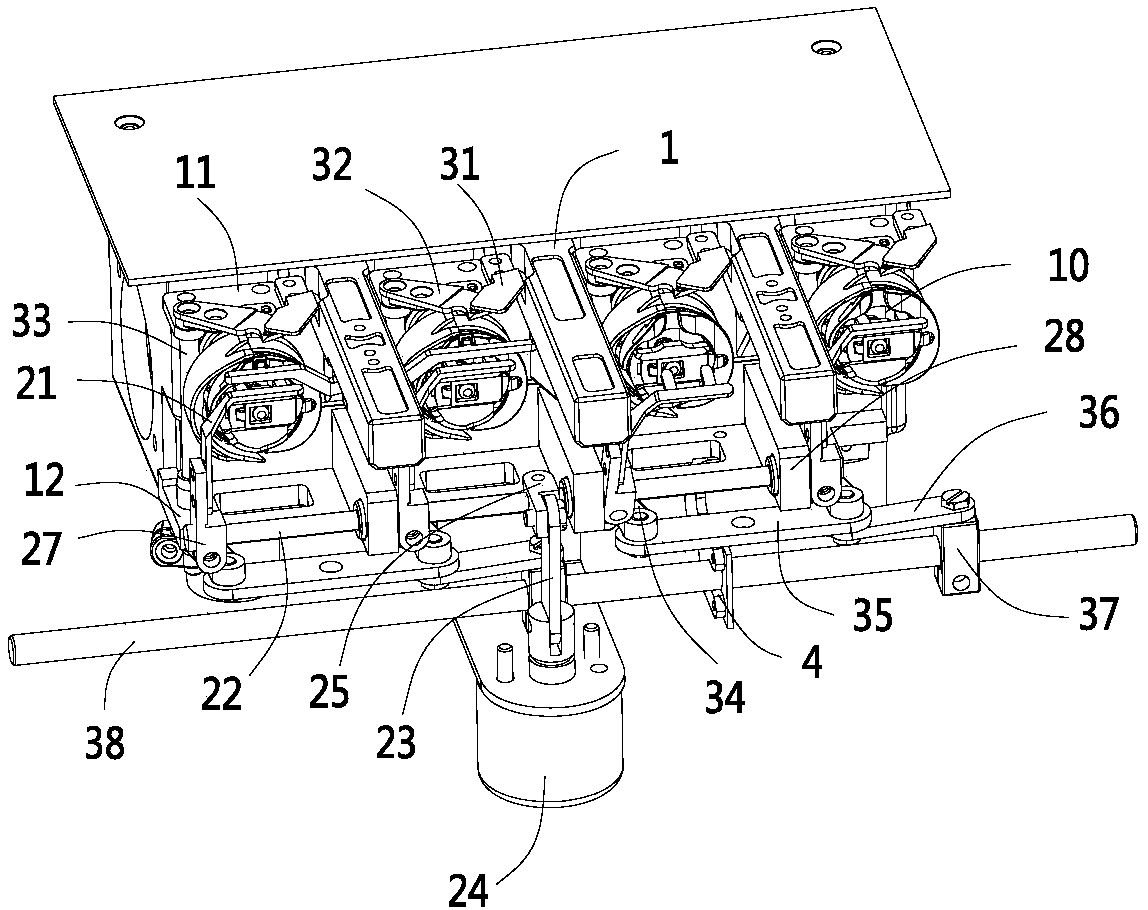

[0034] Such as Figure 1 to Figure 6 As shown, an embroidery machine includes an embroidery machine head, a shuttle box 1, a thread fastening device and a thread trimmer, the shuttle box 1 is provided with a rotary hook 10, and the thread fastening device includes a movable hook mounted on the shuttle box 1 and is used to fasten the thread. Referring to the fastening thread member 21 of the rotary hook 10, the thread trimming device includes a fixed knife 31 and a moving knife 32 that moves relative to the fixed knife 31, an embroidery machine head, a shuttle box 1, a thread fastening member 21, and a moving knife 32. , fixed knife 31, this type of structure is relatively common in the field of embroidery machines, and will not be elaborated here. At the same time, in order to make the drawings more concise, the embroidery machine head is not shown in the drawings.

[0035] It should be noted that the embroidery machine of this embodiment is preferably a double-needle embroide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com