Graphite side heater of layered serpentine polycrystalline silicon ingot furnace

A polycrystalline silicon ingot furnace and heater technology, which is applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problem that the single-layer graphite side heater is difficult to meet the double-layer requirements, and affects the melt convection growth crystal solid-liquid Improve the convection of molten silicon, enhance the uniformity of the thermal field, and save the space of the thermal field by solving problems such as interface stability, feeding amount, and the increase in the size of the silicon ingot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

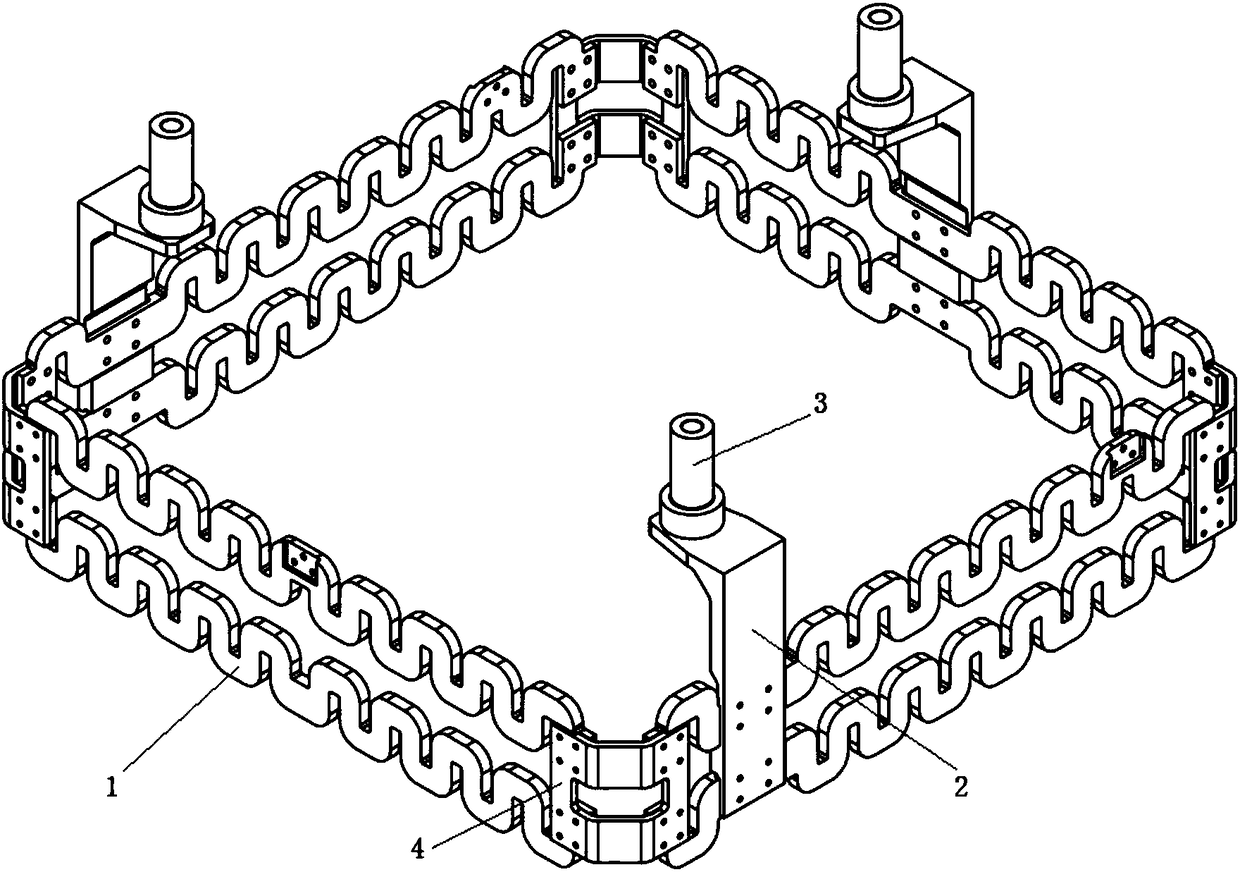

[0025] The graphite side heater of a layered serpentine polysilicon ingot furnace provided in this embodiment has a structure such as Figure 1-2 As shown, it includes 8 pieces of side heater units 1, 3 booms 2, 3 electrodes 3 and 4 corner connecting plates 4. Both side heater units 1 and electrodes 3 are made of graphite materials. All of them are detachably connected in the form of nuts and screws.

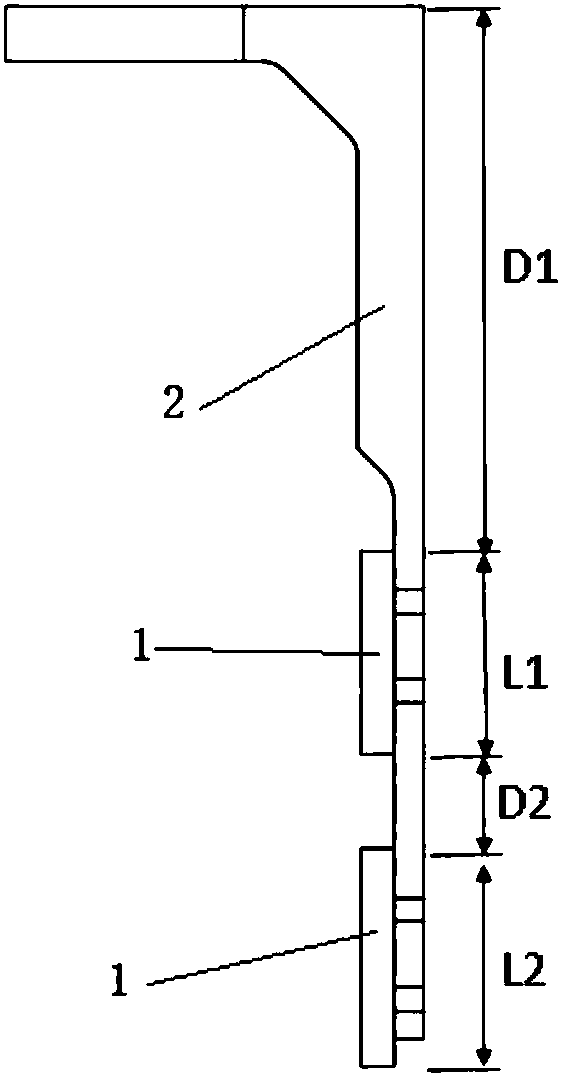

[0026] The side heater unit 1 includes several serpentine periods, and there is a gas gap between adjacent serpentine periods, and the width of the gas gap is 5-50mm. The upper layer heater and the lower layer heater are composed of 4 pieces in each layer, the height L1 of the upper layer heater is > 20mm, and the height L2 of the lower layer heater is > 20mm.

[0027] The boom 2 is L-shaped, and the middle and lower sections of its long arm are connected to the upper heater and the lower heater, so that the upper heater and the lower heater are connected in parallel, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com