Preparation method and application of hydrated basic zinc pyrovanadate (Zn3V2O7(OH)2.2H2O) material

A 2·2H2O, zinc pyrovanadate technology, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problem of low electronic conductivity and ionic conductivity, not suitable for high-power power batteries, and large particles of negative electrode materials. and other problems, to achieve uniform size distribution, good rate cycle performance, and good crystallinity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of hydration basic zinc pyrovanadate (Zn 3 V 2 o 7 (OH) 2 2H 2 O) the preparation method of material is to make as follows:

[0039] 1mmol vanadyl acetate VO(Ac) 2 Dissolve 1.5mmol of zinc chloride in 100ml of dimethylformamide solvent in turn, stir well to obtain a dark green solution, then transfer the resulting dark green solution to a stainless steel reaction kettle, put the reaction kettle into an oven and heat to 120°C After constant temperature reaction for 3h, finally cooled to room temperature, the obtained product was alternately washed with distilled water and absolute ethanol for 3 times, centrifugally filtered, and vacuum-dried to obtain the product hydrated basic zinc pyrovanadate (Zn 3 V 2 o 7 (OH) 2 2H 2 O) Materials.

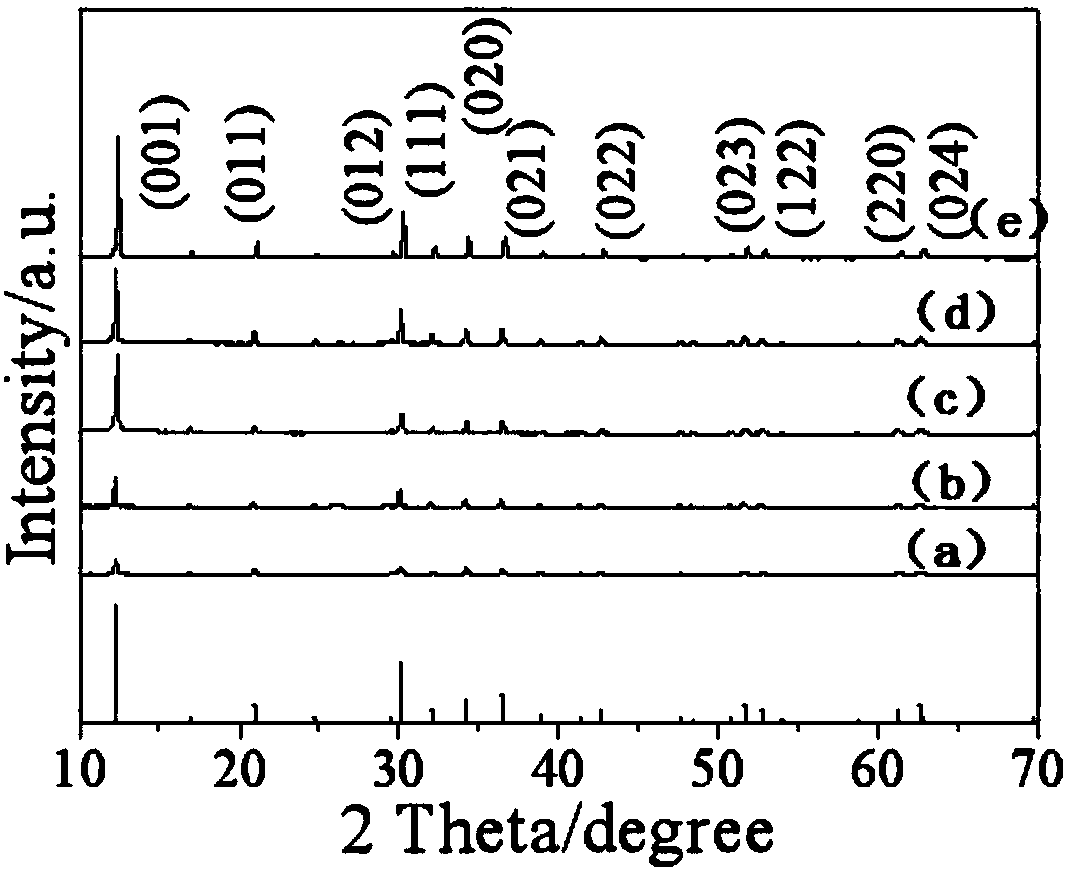

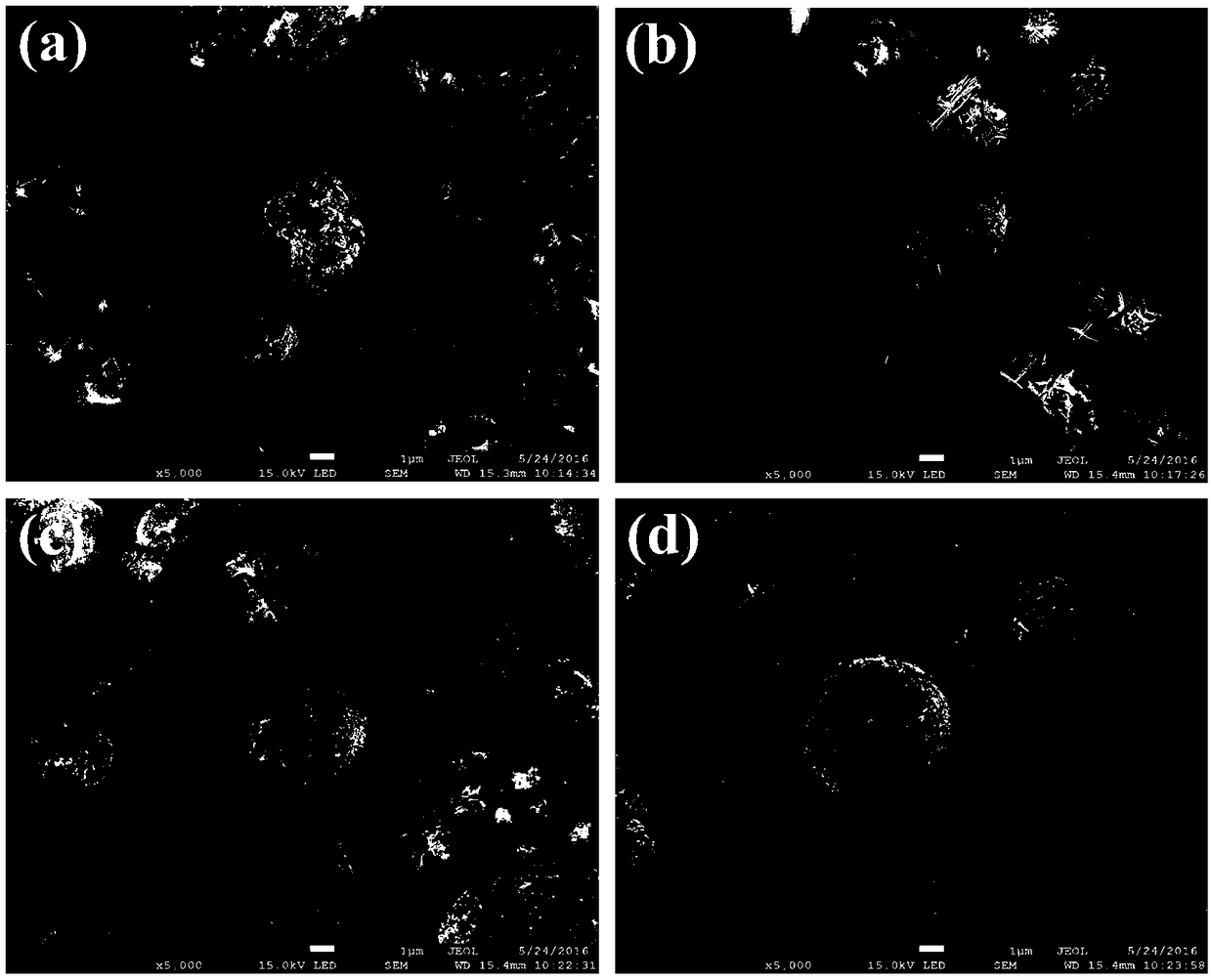

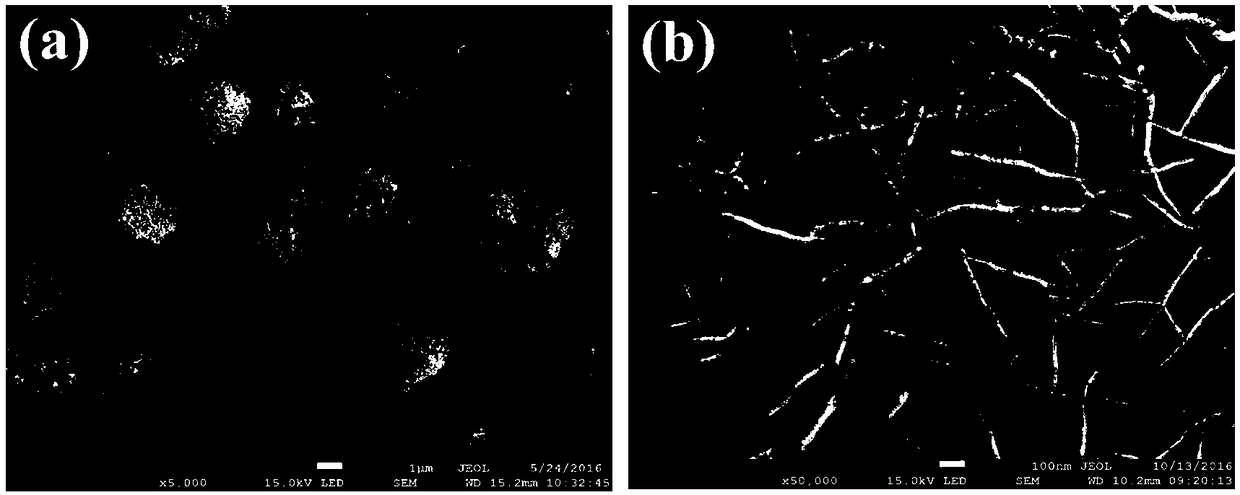

[0040] The product hydration basic zinc pyrovanadate (Zn 3 V 2 o 7 (OH) 2 2H 2 O) The X-ray diffraction results of the material are as figure 1 Shown in (a), product SEM results are as follows figure 2 In (a) show...

Embodiment 2

[0044] A kind of hydration basic zinc pyrovanadate (Zn 3 V 2 o 7 (OH) 2 2H 2 O) the preparation method of material is to make as follows:

[0045] 1mmol vanadyl acetate VO(Ac) 2 and 2mmol of zinc chloride were dissolved in 100ml of dimethylformamide solvent in sequence, and a dark green solution was obtained after stirring evenly, and then the obtained dark green solution was transferred to a stainless steel reaction kettle, and the reaction kettle was heated to 180°C in an oven React at a constant temperature for 6 hours, and finally cool to room temperature. The resulting product was washed alternately with distilled water and absolute ethanol for 3 times, then centrifugally filtered, and vacuum-dried to obtain the product hydrated basic zinc pyrovanadate (Zn 3 V 2 o 7 (OH) 2 2H 2 O) Materials.

[0046] The product hydration basic zinc pyrovanadate (Zn 3 V 2 o 7 (OH) 2 2H 2 O) The X-ray diffraction results of the material are as figure 1 Shown in (b), the pro...

Embodiment 3

[0050] A kind of hydration basic zinc pyrovanadate (Zn 3 V 2 o 7 (OH) 2 2H 2 O) the preparation method of material is to make as follows:

[0051] 1mmol vanadyl acetate VO(Ac) 2 Dissolve 2.5mmol zinc chloride and 2.5mmol zinc chloride in 100ml of dimethylformamide solvent in turn, stir well to obtain a dark green solution, then transfer the obtained dark green solution to a stainless steel reaction kettle, put the reaction kettle into an oven and heat to 180°C After the reaction at constant temperature for 12 hours, finally cooled to room temperature, the resulting product was alternately washed with distilled water and absolute ethanol for 3 times, centrifugally filtered, and vacuum-dried to obtain the product hydrated basic zinc pyrovanadate (Zn 3 V 2 o 7 (OH) 2 2H 2 O) Materials.

[0052] The product hydration basic zinc pyrovanadate (Zn 3 V 2 o 7 (OH) 2 2H 2 O) The X-ray diffraction results of the material are as figure 1 Shown in (c), the product scanning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com