Manual hydraulic forklift for constructional engineering and operating method

A construction engineering and forklift technology, applied in the field of manual hydraulic forklifts for construction engineering, can solve the problems of low work efficiency and high work intensity, and achieve the effects of improving work efficiency, reducing work intensity and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

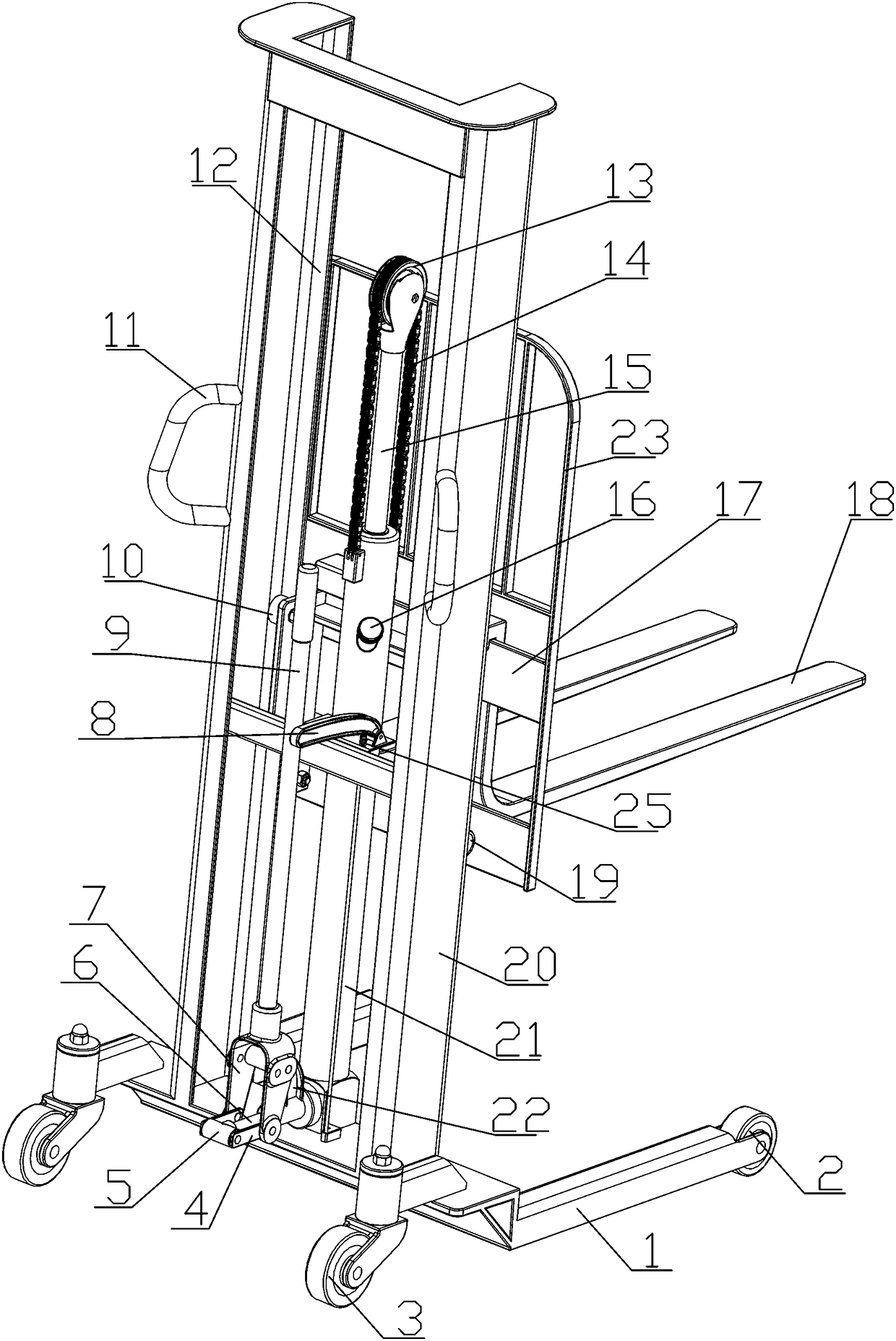

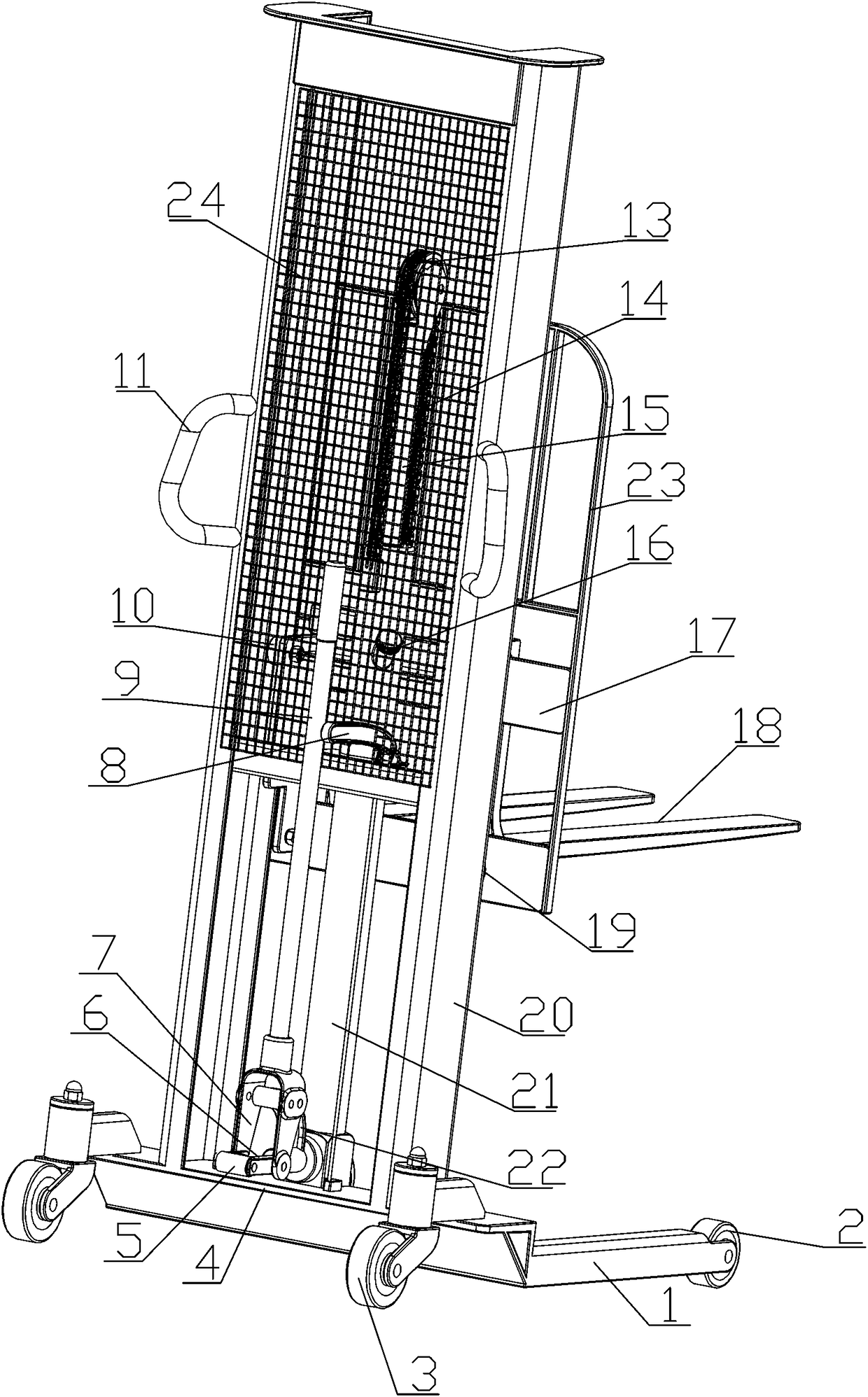

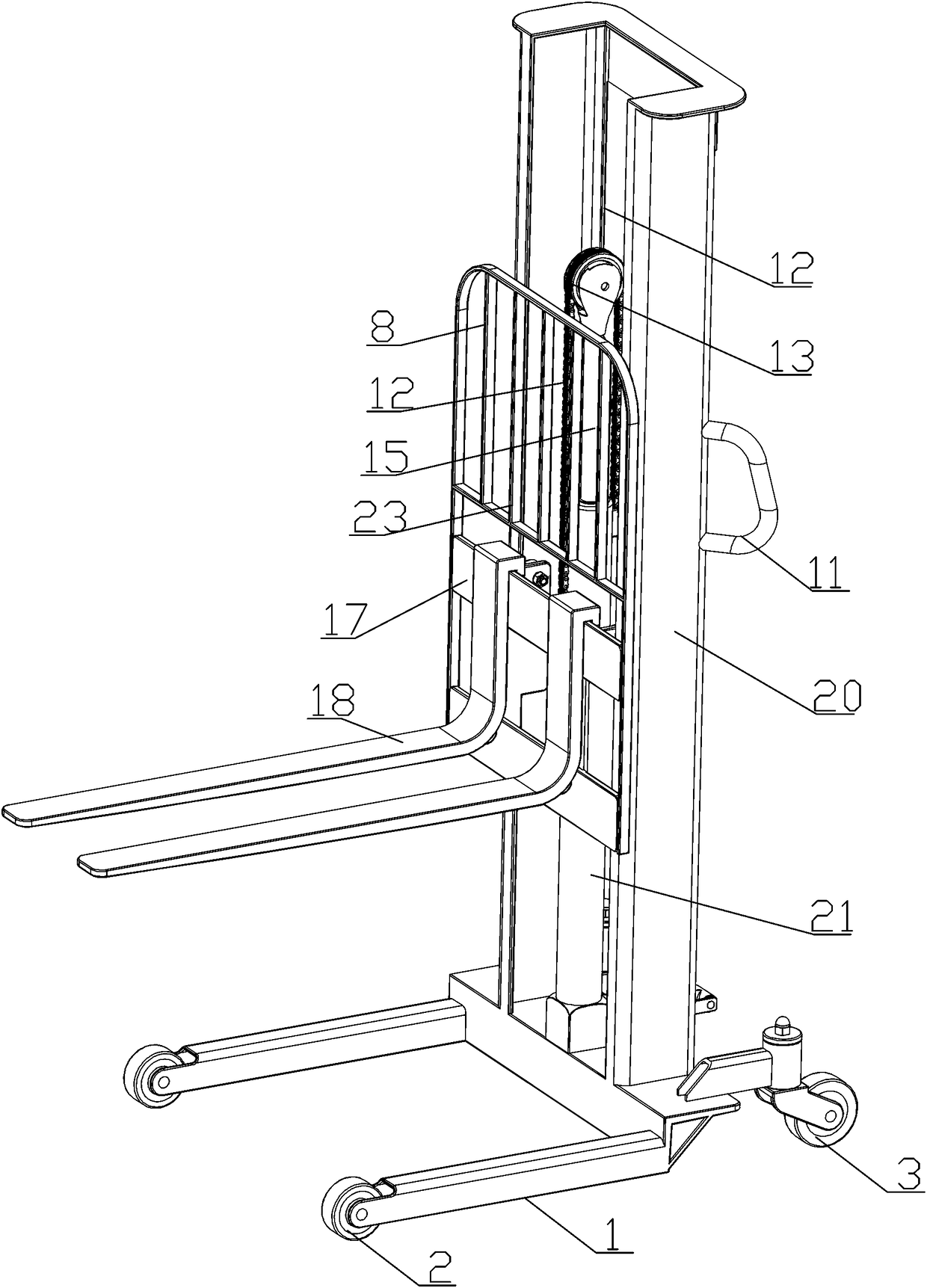

[0032] see Figure 1-3 , a manual hydraulic forklift for construction engineering, which includes a forklift floor 1, a roller 2 is installed at the front end of the forklift floor 1, and a universal wheel 3 is installed at the rear end; Vertically fixed with parallel column 20, the inner side wall of described column 20 is provided with slide rail guide plate 12, on described slide rail guide plate 12, lifting plate 17 is installed with sliding fit, and the top of described lifting plate 17 passes lifting chain 14 Engaged with the sprocket 13 of the hydraulic jacking mechanism, the other end of the lifting chain 14 is fixed on the hydraulic cylinder block 21 of the hydraulic jacking mechanism, and the hydraulic cylinder block 21 is fixedly installed on the forklift floor 1 and is located between between 20 uprights. The above-mentioned manual hydraulic forklift can conveniently carry and lift the building materials on the construction site, thereby replacing manual work, imp...

Embodiment 2

[0042] The use method of any one of the manual hydraulic forklifts for construction engineering, it includes the following steps:

[0043] Step1: Push the hydraulic forklift to the position where the goods need to be moved, and push the forklift plate 18 into the bottom of the building materials;

[0044] Step2: Manually operate the long rod 9 to drive the telescopic movement of the plunger rod 6 through the operation of the long rod 9, and then drive the plunger pump to inject oil into the hydraulic cylinder 21;

[0045]Step3: Drive the piston rod 15 of the hydraulic cylinder 21 through the plunger pump to lift, and then lift the sprocket 13 through the piston rod 15, and lift the lifting plate 17 at one end of the chain 13 through the cooperation of the sprocket 13 and the lifting chain 14 ;

[0046] Step4: Drive the forklift plate 18 to lift through the lifting plate 17, and then lift the building materials. After it leaves the ground, operate the cylinder body to lock the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com