Multifunctional electric power construction machine

An electrical construction, multi-functional technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of single function, inability to adjust the distance between different cables on the conveyor belt, and inconvenient operation, etc. Increase functionality, optimize convenience, and facilitate delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

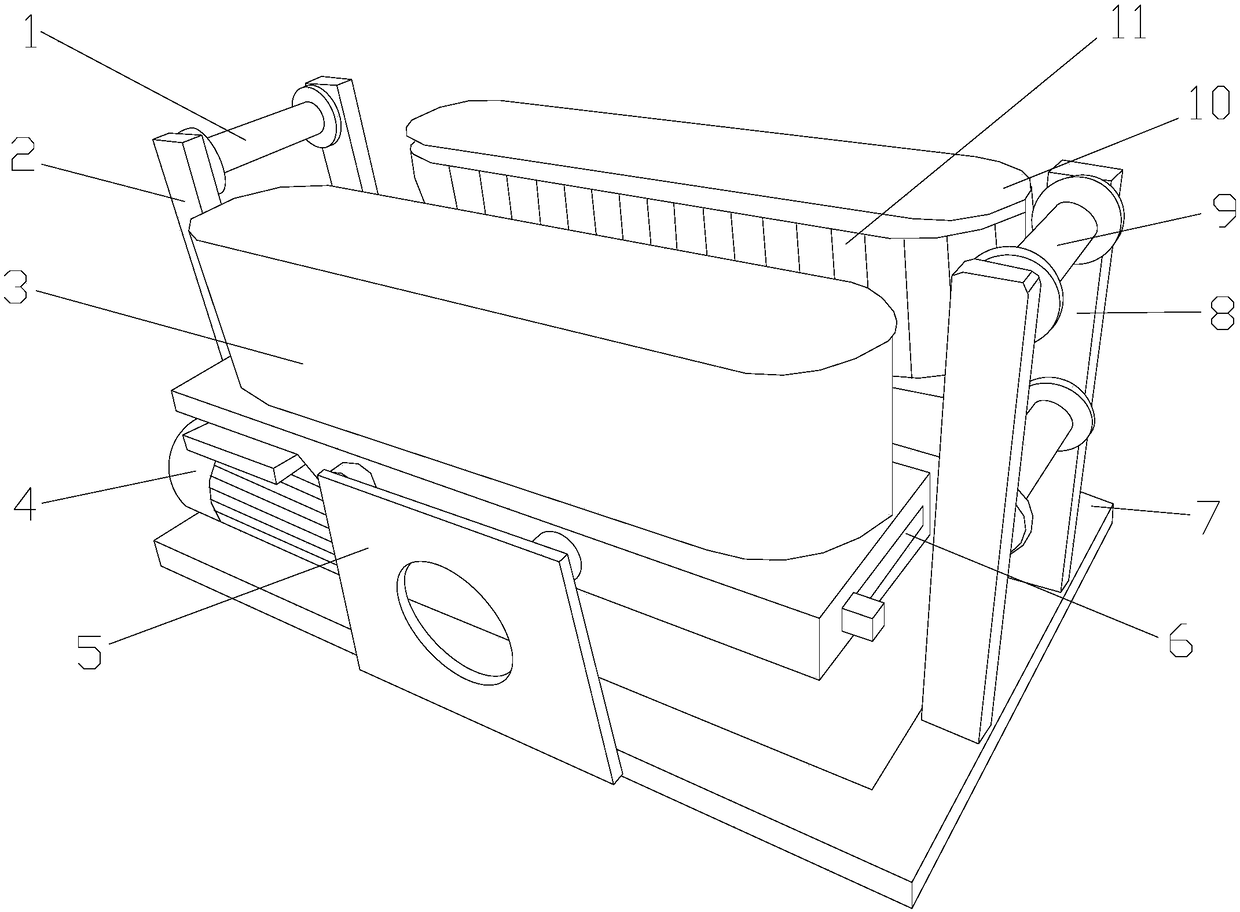

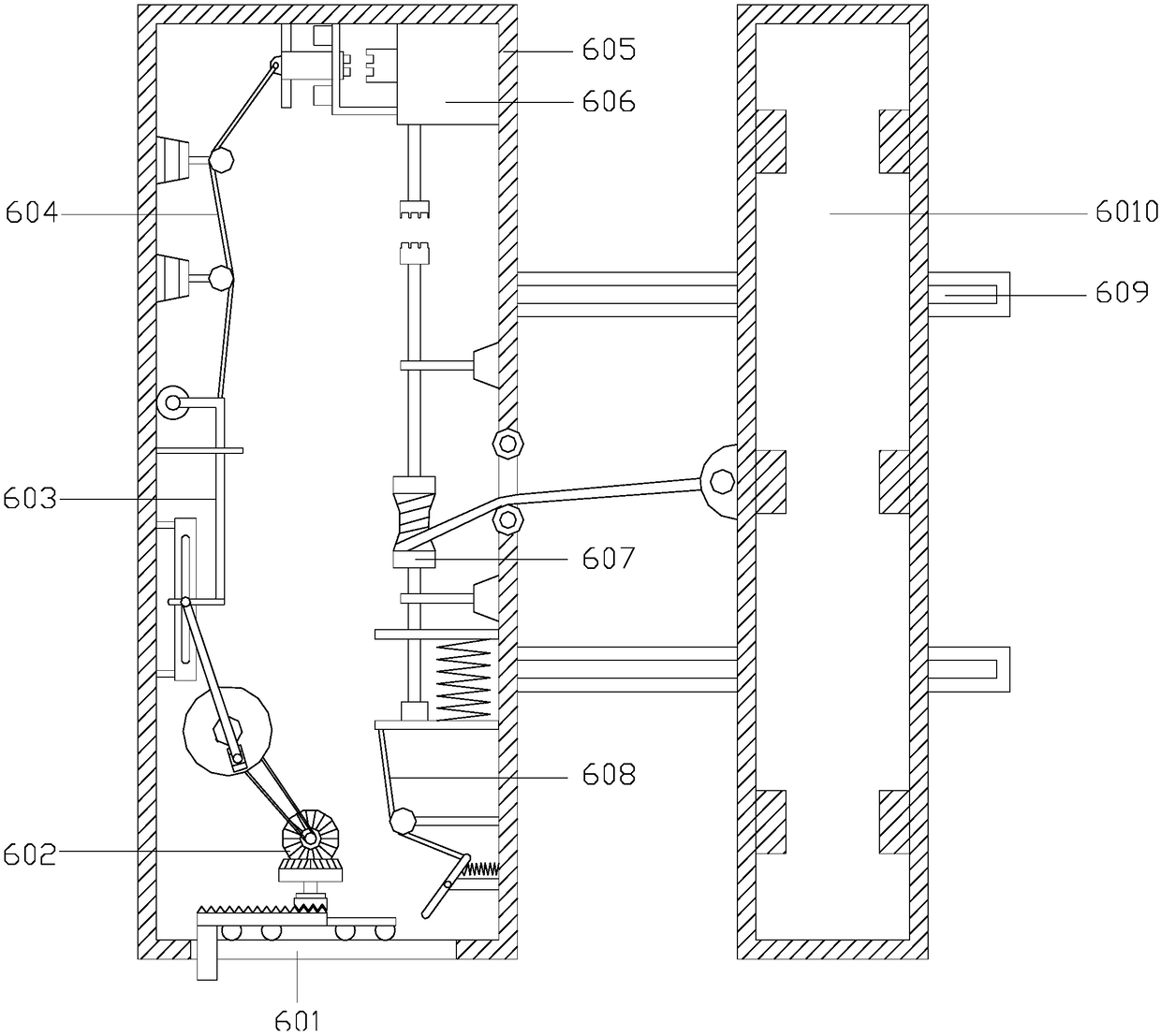

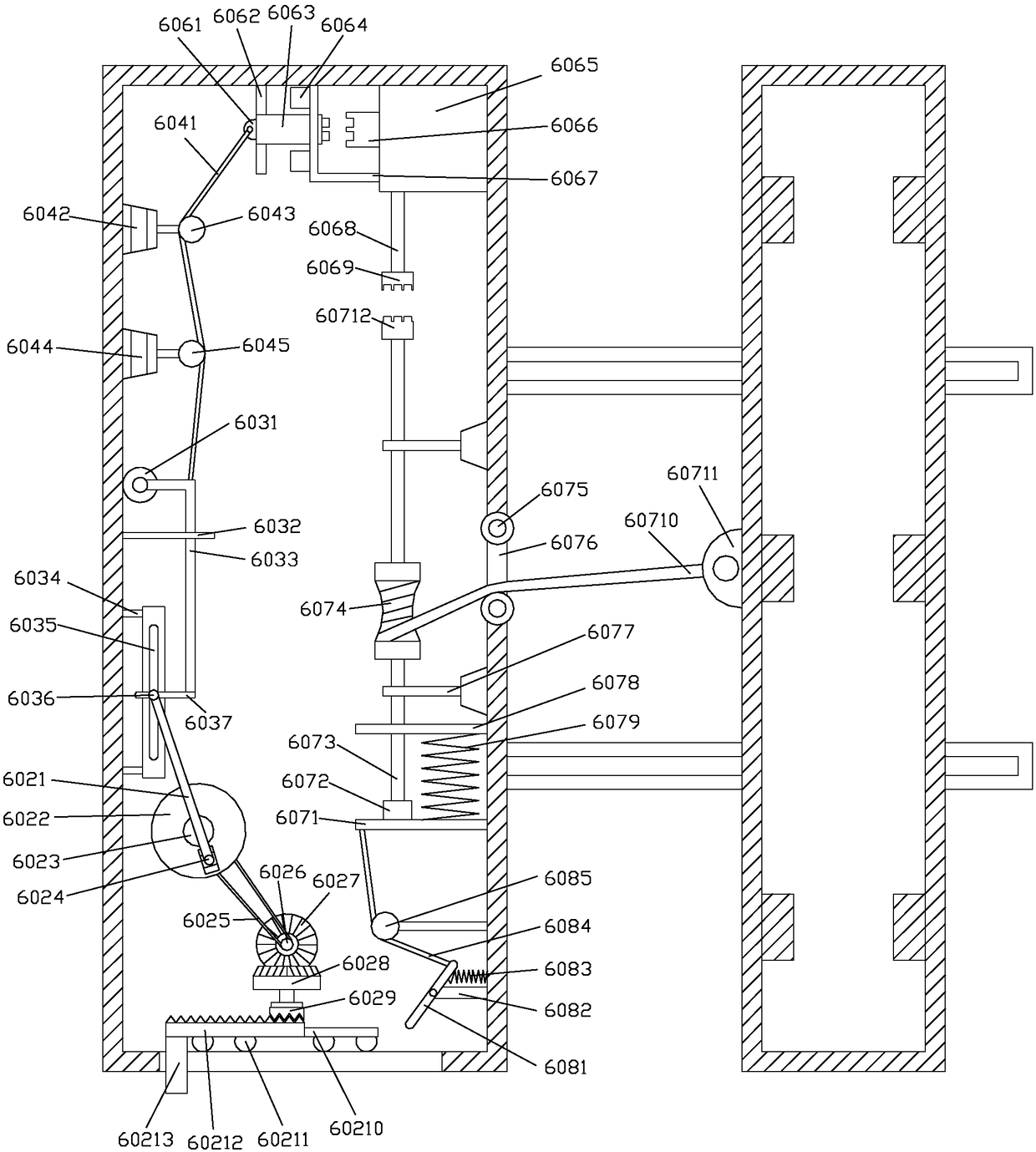

[0027] see Figure 1-Figure 7 , the present invention provides a kind of multifunctional electric power construction machine: its structure comprises wire-feed roller 1, wire-feed frame 2, main conveyer 3, drive motor 4, mounting plate 5, adjusting device 6, fixed bottom plate 7, wire-out frame 8, Outlet roller 9, auxiliary conveyor 10, conveyor belt 11, two mounting plates 5 are installed on both sides of the middle of the fixed bottom plate 7 by welding, and the bottom of the wire inlet frame 2 is installed on the bottom by embedding. The front end of the fixed bottom plate 7, the rear end of the fixed bottom plate 7 is provided with a groove at the bottom of the wire outlet frame 8 which is movable, and the wire outlet roller 9 is installed on the upper end of the wire outlet frame 8 by buckling, and the wire inlet roller 1 Installed on the upper end of the wire inlet frame 2 by buckling, the two sides of the adjustment device 6 are connected with the mounting plate 5 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com