Line winding-up mechanism of spinning type fishing line reel

A technology of a reeling mechanism and a fishing reel, which is applied in the fishing reel, fishing, application, etc., can solve the problems of twisting and deformation of the fishing reel, inability to rotate, and difficult to locate, so as to avoid twisting and deformation, facilitate operation, and avoid interfering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

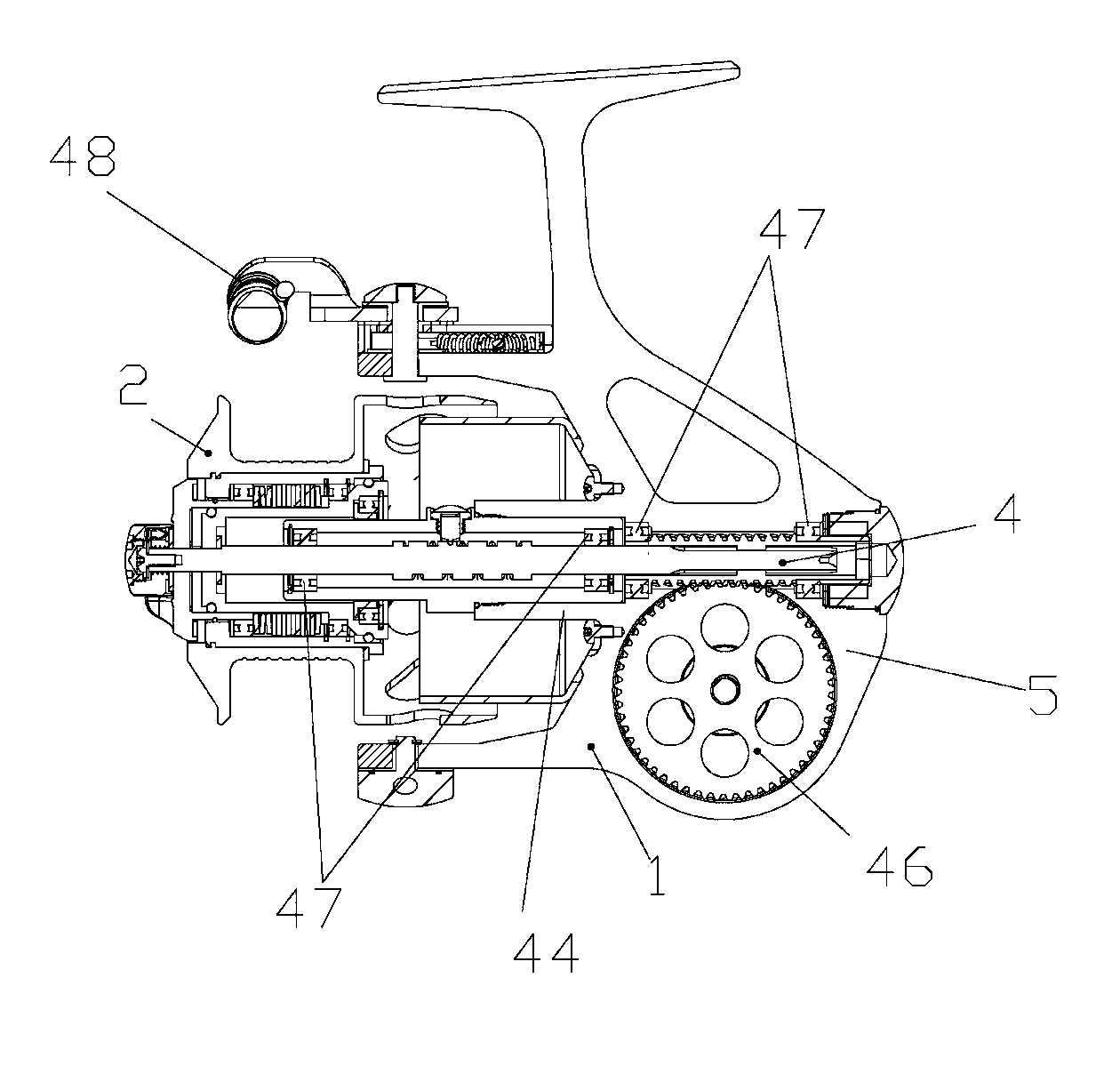

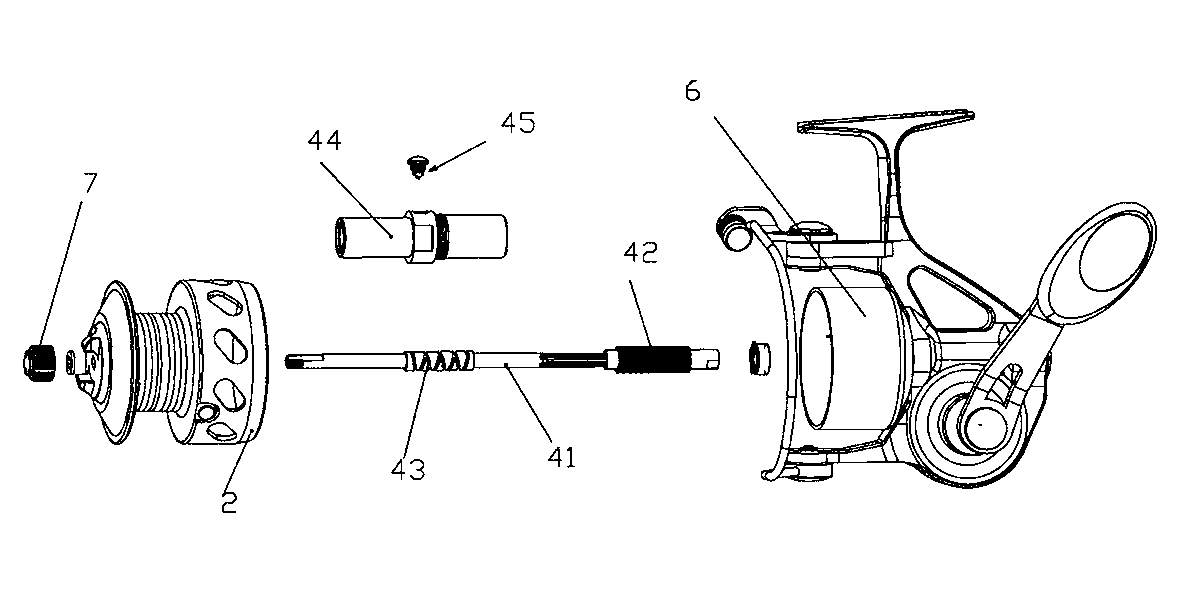

[0012] The present invention will be further described below with reference to the accompanying drawings.

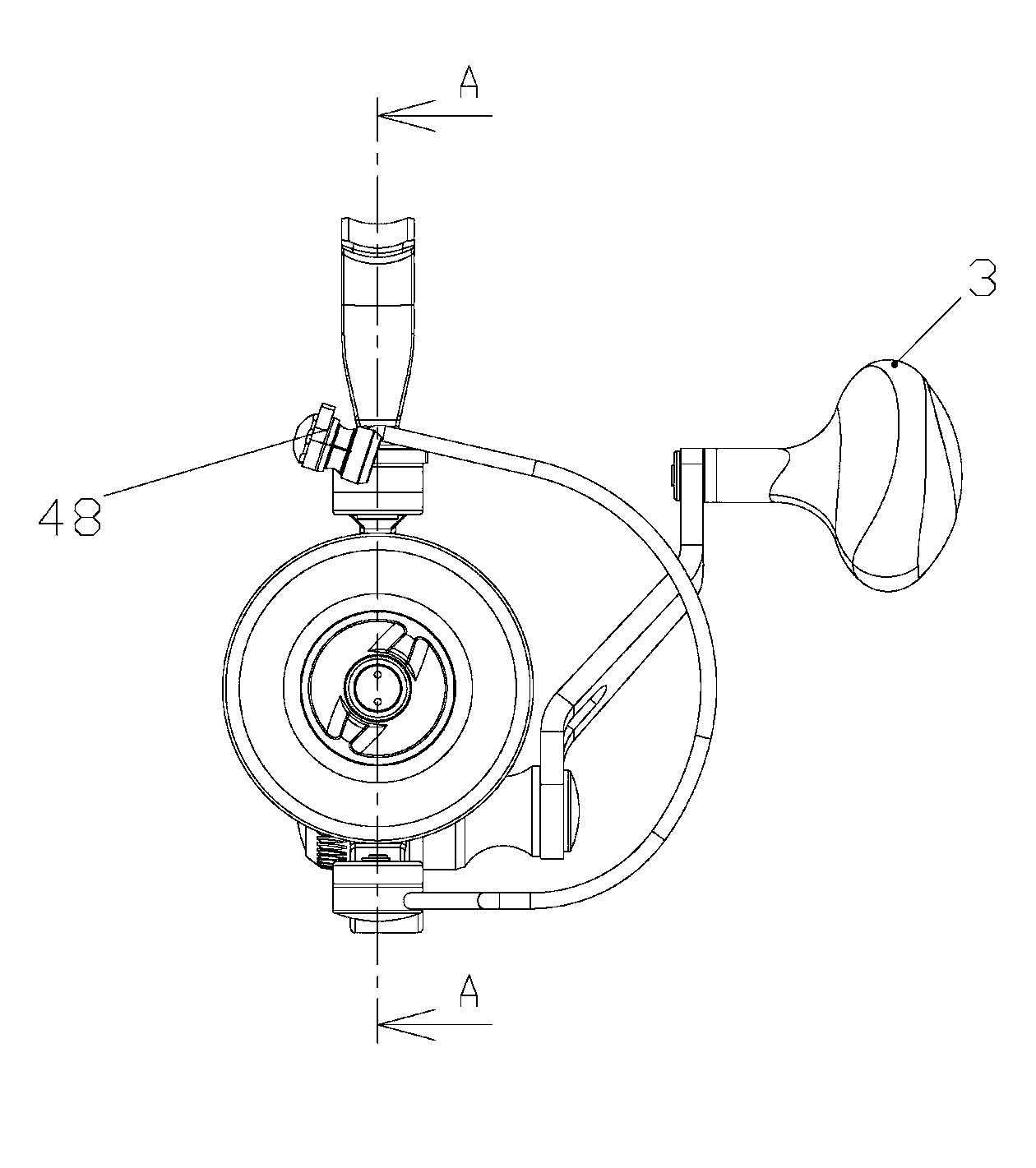

[0013] Such as figure 1 , figure 2 and image 3 As shown, a spinning wheel type fishing reel take-up mechanism includes a main body 1, a throwing reel seat 48 is provided in the middle of the main body 1, a reel 2 is provided at one end of the main body 1, and a handle 3 is provided on one side of the main body 1. The wire wheel 2 is connected to the handle 3 through the transmission device 4, the transmission device 4 includes a main shaft 41 which is installed in the main body 1, one end of the main shaft 41 is sleeved with a driven gear 42, the other end of the main shaft 41 is connected with the wire wheel 2, the main shaft The middle part of 41 is provided with a helical groove 43, and the position corresponding to the helical groove 43 in the middle part of the main shaft 41 is provided with a sleeve 44, and the guide pin 45 hinged with the helical groove 43 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com