Horizontal type take-up frame

A wire take-up, horizontal technology, applied in the field of horizontal take-up, can solve the problems of different wire arrangement requirements, multiple wire reel specifications, and inability to be used universally, and achieve the effect of high wire take-up quality and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

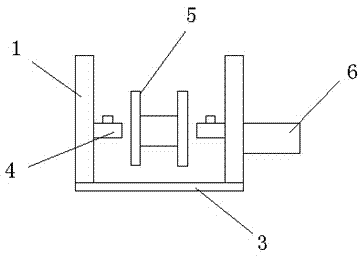

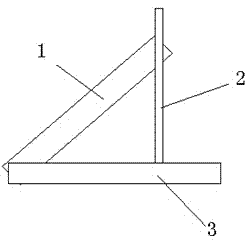

[0011] A horizontal take-up stand, see figure 1 and figure 2 , the wire take-up frame includes an adjustable suspension rod 1, a vertical support rod 2 and a telescopic transmission and locking device 3. The bottom ends of the two mutually parallel vertical support rods are fixed on the horizontal fixed base 4 and are respectively located on the horizontal fixed base. On both sides of the spool, the distance between the two mutually parallel vertical support rods is adapted to the width of the spool 5 . The two vertical support rods are provided with symmetrical adjustable suspension rods, the lower end of the adjustable suspension rod is hinged on the horizontal fixed base, and the upper end is connected with the vertical support rod in an adjustable up and down manner; the connection method is: on the vertical support rod A set of connecting holes is arranged from top to bottom along the axial direction, the upper end of the adjustable suspension rod is provided with conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com